Industrial furnace machinery is utilized in a wide range of industries. The selection of industrial furnace machinery is primarily left for engineers to handle. However, even engineers will need extra guidance to make the perfect pick for the organization.

The cost of industrial furnace machinery is on the high side, but this isn’t the only reason why selecting the perfect machinery is an important consideration. It’s also essential because picking the most suitable machinery will have a positive impact on the general productivity and result of the project at hand.

Table of Contents

Primary industrial furnace machinery

Machinery specifications and features

Step-by-step guide on how to select industrial furnace machinery

Conclusion

Primary industrial furnace machinery

Several furnaces are used in commercial and industrial setups for metal and refinement. These equipment vary based on the materials being processed and the level of refinement being enacted on the material. Here are a few machines used in heat generation to process these materials.

Industrial ovens

An industrial oven is a heated chamber machine for drying, baking, and curing refined materials. These ovens operate at extremely high temperatures to heat, cure, and condition metals during industrial applications.

These ovens are also called commercial ovens. Laboratory, batch, and industrial conveyor ovens are the three fundamental types of industrial ovens. In high-volume production procedures, industrial ovens with conveyors and batches are employed.

Chamber furnaces

The chamber furnace is a piece of essential machinery for metal treatment. They are utilized in almost every form of heat treatment and thermal processing.

Chamber furnaces are frequently used for preheating, tempering, and heat treatment at temperatures ranging from 40 to 1200 degrees Celsius.

Metal melting furnaces

Metal melting furnaces heat solid materials to the point of liquefaction. In addition, thermal processing machinery is frequently used to modify materials’ surface or interior properties by gradually raising their temperature. This increases their malleability and ductility.

Drying ovens

Drying ovens are industrial-heated chambers that extract moisture from processed materials. Their primary applications include evaporations, temperature testing, and sterilizations.

These ovens often feature a fan or turbine that starts the convection process, which warms and dries the items within.

Polymerization ovens

Polymerization ovens, also called curing ovens, are utilized to artificially “grow” these polymers in high-temperature conditions and promote substantial connections between monomers.

Infrared ovens

Due to their high power density and heat transmission, infrared ovens are appropriate for quick heating in many applications. The utility of these ovens during heat application increases the output and conveyor speed rate by 30%.

Conveyors

Conveyor machines are utilized for multiple operations. Most of these operations revolve around preheating, drying, curing, aging, bonding, and forming. In addition, conveyor ovens may be added to existing manufacturing lines and used for continuous processing.

Machinery specifications and features

Here are a few specifications to look out for when shopping for industrial furnace machinery:

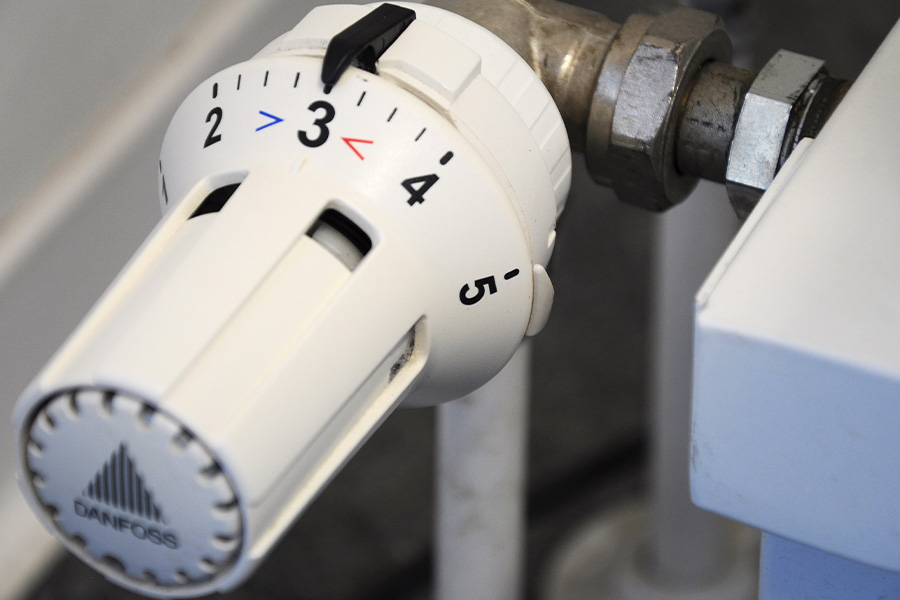

Temperature regulation

Temperature regulators are critical for regulating temperature in many industrial processes. Temperatures that are permitted to drift too high or too low might not only harm the ultimate product but can also impair the production process.

Conversely, an absence of temperature management harms the machinery and employees, affecting the success of the industrial process.

Air filtration

Air filtration is essential in industrial settings to extract contaminants from the environment, improve air quality, and protect personnel health.

Most of the time, replacing the filters three to four times a year is enough. However, if the personnel in the industry have compromised immune systems, the efficacy of the filtration systems must be checked more regularly.

Warranty

Before signing the purchase agreement, all purchasers must evaluate the warranty of each piece of machinery they plan to acquire. Warranties allow business owners to request that the manufacturer resolve any difficulties that arise following their conditions of purchase.

For example, most furnace machinery comes with a 10-year limited components guarantee and 20-year coverage on the heat exchanger, which is the furnace’s heart and the most expensive component to repair or replace.

Variable speed options

Variable speed options provide for precise adjustment of motor output and power consumption. For example, with fans, there would be a significant decrease in the energy necessary for handling the load at a reduced pace or frequency.

In addition to conserving energy, variable speed drives may help decrease maintenance expenses, waste, and noise pollution.

AFUE

The annual fuel utilization efficiency is a vital machine feature to be considered during purchase. The AFUE rating of a gas furnace assesses its energy efficiency.

The percentage is significant because it informs operators how much of the fuel purchased is transformed into heat. AFUE rating for an industrial furnace is comparable to car MPG ratings.

Product size

The size/mass of the primary materials being produced must also be considered during machine selection.

Bigger machines, as expected, can handle a higher mass and improve the rate of production. However, when the budget is restricted, business owners have no other choice than to settle for smaller machines that they can afford.

Applicable material

Some materials can be flammable, explosive or sensitive to light. The machines chosen have to be compatible with the nature of the primary material or else the quality of the final product might be affected.

Step-by-step guide on how to select industrial furnace machinery

Consider production needs

The first requisite of purchasing a machine is to estimate the needed characteristics based on the size of the project and its precision requirements. After this assessment, manufacturers can draw a list of the essential machinery to invest in at this time.

Find a vendor

Manufacturers must opt for vendors capable of understanding the project’s technical requirements to be handled. Only vendors with extensive expertise and solid technical capabilities can immediately guarantee results.

The aim is to get equipment that does not require changes after the first batch exits the furnace, and to avoid modifying the design of the furnace.

Select based on budget

Generally, the budget for all industrial machinery should be 2-5% of the total business regulatory asset value (RAV). However, business owners can decide to go above or below this stated ratio.

Conclusion

No setup can function without machinery to enhance the rate of production. It’s therefore necessary for business owners to invest in viable machines that would be efficient over a long timespan. For those interested in learning more, check out the Industrial furnace machinery product listings on Alibaba.com