It may be challenging to identify and purchase a computer numerical control (CNC) [LCH1] wood router that suits the market’s needs. Besides knowing how to distinguish quality machines from their less reliable counterparts, there are also different types and models of machines to consider.

In order to ensure you choose the best option for you or your customers, this guide will highlight the different CNC wood routers available. It will also offer some useful tips to keep in mind when shopping for a new machine, as well as a brief overview of the market for CNC wood routers.

Table of Contents

CNC wood routers: market share and demand

Key tips to consider before buying a CNC wood router

Types of CNC wood routers on the market

Target market and market growth for CNC wood routers

CNC wood routers: market share and demand

The CNC wood router market was valued at US $649.9 million in 2020. Of this, China held the largest share at 34%. This was followed closely by North America, which had an 18% share, while Europe’s market share came in at 13%.

Even though the pandemic impacted the import and export of wood routers in 2020, it is projected that sales will recover, due to their ease of use and their ability to replace several other types of machines, specifically boring machines, spindle molders, and panel saws.

Key tips to consider when buying a CNC wood router

The size of the machine bed

The bed size of the CNC wood router should be sufficient enough that it remains stable to ensure the machine can operate accurately. In addition, the size of the machine bed will determine the types of materials that can be processed. Small wood routers tend to have dimensions of 2 ft x 3 ft, making them suitable for smaller pieces of wood, while more extensive machine beds of 4 ft x 4 ft and even 2100mm x 4500mm [LCH3] allow for processing of larger wood panels.

How the tools are changed

There are versions of the CNC wood routers that change tools manually or automatically. The advantage of having a machine capable of automatically changing the tools is that this increases overall efficiency when working. Besides this, wear and tear is generally reduced, while the machine’s service life is extended.

The machine’s transmission mode

There are two transmission modes for CNC routers: the rack drive and the screw drive. The screw drive is slow and very precise. It has a high environmental requirement and short service life. On the other hand, the rack drive is faster than the screw drive, yet still offers high precision of 0.1 mm.

The machine’s motor

The speed of the motor will have a direct impact on the machine’s efficiency. CNC wood routers either use a stepper motor or a servo motor. The stepper motor is easy to use and reliable. It has a low operation cost and has a simple structure. On the other hand, the servo motor has a long service life, provides high precision, and is fast. Businesses that need to process a lot of wood should therefore opt for the servo motor over the stepper motor.

The router spindle

Because the router spindle always gets heated while in operation they tend to have two cooling mechanisms: air-cooled spindles and water-cooled spindles. Air-cooled spindles are suitable for places that don’t have easy access to water. They use fans to cool the spindle, they come with a low maintenance cost, and they are simple to operate. Water-cooled spindles, on the other hand, can cool the spindle while in operation, and they are less noisy, as well as being highly efficient at cooling.

The router control system

The router control system refers to how the machine moves or operates. The Gantry router uses a rail system to move the spindle, while the spindle for the firm or fixed bridge router is held in place, and does not require any control system.

Spindle power

This refers to the revolutions per minute (rpm[LCH4] ) of a spindle. When choosing the power of the spindle one should consider the material being milled by the machine. For a machine that will mill wood or aluminum materials, an rpm of 24,000 and power of 1kW will be sufficient. For steel, an rpm of 15,000 – 18,000 and power of 1kW would be enough.

Types of CNC wood routers on the market

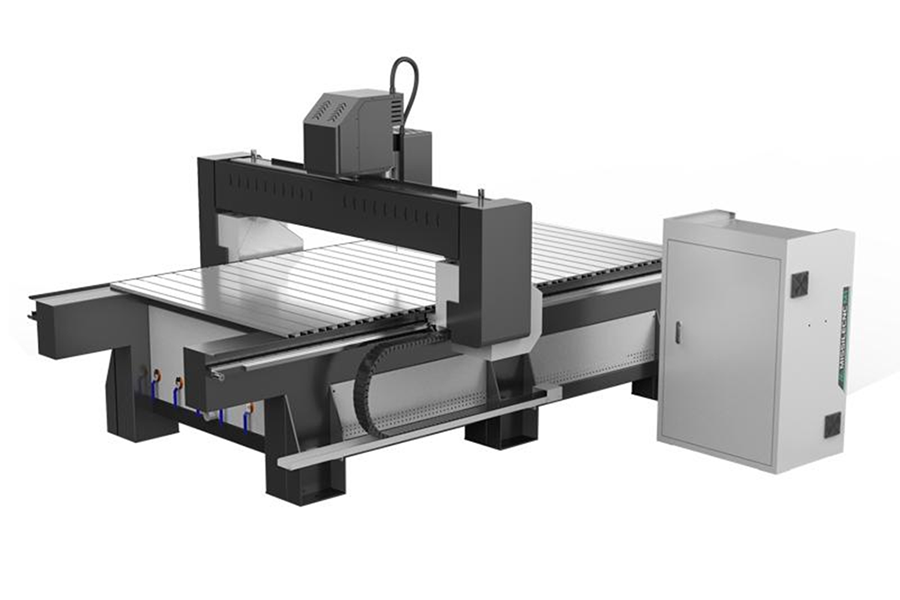

Gantry style CNC wood router

The Gantry style CNC wood router has a movable component that carries the spindle as it engraves the wood.

Features:

● The spindle is attached to a movable component to allow it to engrave the wood.

● It cuts using the X-Y coordinate system.

Pros:

● It can be adjusted to fit different sizes of wood.

● The machines are light and easy to move around.

Cons:

● It may be less accurate because the gantry can be misaligned.

● It’s more complex to operate than other routers, and hard to maintain.

Fixed bridge CNC wood router

The firm or fixed bridge CNC wood router features an immovable bridge to rest the spindle.

Features:

● It has a cast iron fixed bridge.

● It has independently controlled vacuum zones for each table.

● It has over 14 inches of Z-axis clearance.

Pros:

● It is very accurate.

● It is easy to operate and maintain.

Cons:

● The machines are heavy.

Target market and market growth for CNC wood routers

The CNC wood router market is expected to grow to US$ 832.4 million by 2028, with a compound annual growth rate of 3.6%. The Asia Pacific region is expected to have the greatest demand for CNC wood routers. This is because of increased industrialization in this region, and robust economic growth. Europe will be the second-largest market for CNC wood routers because of steady demand for new technologies.

Conclusion

CNC wood routers are forecast as a high-growth industry with the potential to transform how things are produced globally. Given that there are many things to consider when selecting a CNC wood router, this guide highlighted some key considerations for companies that want to venture into this market. Being well-equipped with knowledge of CNC routers before investing, one can be sure to make the best possible decision. For those who want to take the next step, explore the following list of CNC wood routers for more details.

Gгeat article, exactly what I wantеd to find.