This guide tells you all about laser marking machines; what they are, how they work, the benefits they bring, and their potential applications.

Table of Contents

What is a laser marking machine?

How does a laser marking machine work?

Laser marking machine benefits

Laser marking machine applications

Different laser marking machine processes

What is a laser marking machine?

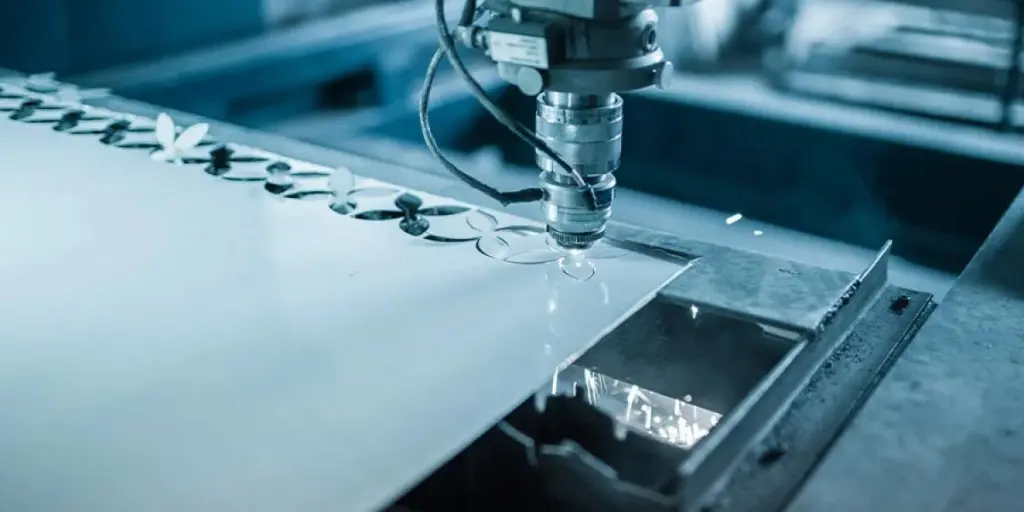

Laser marking uses a laser beam to permanently mark all sorts of objects. The principle behind laser marking is that the laser beam modifies the optical appearance of an object surface through a reaction caused when the laser energy hits the object surface. This can occur through a variety of mechanisms:

1. Ablation of the material (laser engraving); sometimes removing some of the colored surface layer.

2. Melting a metal, thus modifying the surface structure.

3. Slight burning (carbonization) usually of paper, cardboard, wood, or polymers.

4. Transformation (bleaching) of the pigments (industrial laser additives) in a plastic material.

5. Expansion of a polymer, for example by evaporating an additive.

6. Generation of surface features, such as small bubbles for example.

By scanning the laser beam (e.g., with two movable mirrors), it is possible to quickly write letters, symbols, bar codes, and other graphics, using vector or raster scanning. Another method is to use a mask that is imaged on the workpiece (projection marking, mask marking). This method is both simple and fast and can even be used with moving workpieces. However, it is less flexible than scanning.

Laser marking is the marking or labeling of workpieces and materials with a laser beam. We will have a look at the different ways this can happen, such as engraving, removing, staining, annealing, and foaming. Depending on the type of material and the quality you want, each of these procedures has its advantages and disadvantages.

How does a laser marking machine work?

Laser technology basics

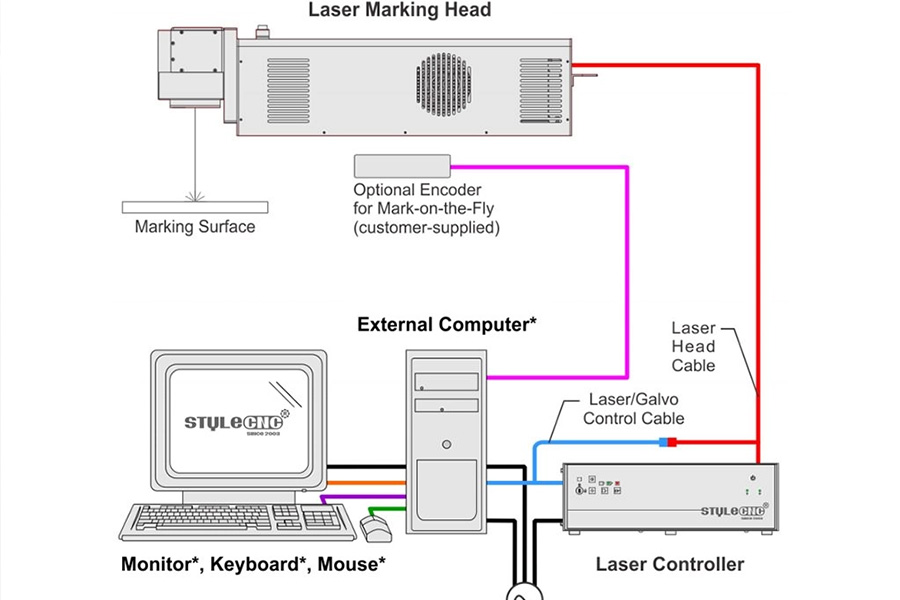

All lasers consist of three principal components:

1. An energy source, usually known as an external pump source.

2. An active laser medium.

3. Two or more mirrors that form the resonator.

1. The pump source guides external energy to the laser and can be optical, electrical, or chemical depending on the active medium.

2. The active laser medium is the material in which the laser action takes place. Depending on the design, it can be a gas mixture (CO2 laser), solid crystals (YAG laser), or optical fibers doped with rare earth metal elements (fiber laser). When energy is pumped into the active medium, it is partially transformed into radiation energy.

3. The resonator builds up the light energy in the laser beam. It’s formed by placing two or more mirrors facing each other so that the light emitted between them is reflected back and forth. One of the mirrors is a one-way mirror. The active laser medium radiation is amplified in the resonator. Only a certain amount of radiation can leave the resonator through the one-way mirror. This is laser radiation.

Laser marking machine benefits

High-precision marking with consistent quality

Thanks to the high precision of laser marking, even very delicate graphics, 1-point fonts, and really small geometries will be clearly legible. At the same time, marking with a laser marker ensures continuous high-quality results.

High marking speed

Laser marking is one of the fastest marking processes available in the market. This results in high productivity and cost benefits for your business. Depending on the material structure and size, different laser sources (e.g., fiber lasers) or laser machines (e.g., galvo lasers) can be used for even faster speeds.

Long-lasting marking

Laser etching is permanent, so will only ever need doing once, and is resistant to abrasion, heat, and chemicals like acids. Depending on the laser parameter settings, certain materials can also be marked without damaging the surface.

Laser marking machine applications

Laser marking machines have a huge variety of applications:

1. Adding part numbers, bar codes, use-by dates, etc., on food packaging, bottles, etc.

2. Adding traceable information for quality control.

3. Marking printed circuit boards (PCBs), electronic components, and cables.

4. Printing logos, bar codes, and other information on products.

Compared with other marking technologies such as ink jet printing and mechanical marking, laser marking has lots of advantages, including very high processing speeds, low operational costs (no use of consumables), constant high quality, long-lasting results, it’s clean, there’s no contamination, and it can mark tiny features while being very flexible.

Plastic materials, wood, cardboard, paper, leather, and acrylic are often marked with relatively low-power CO2 lasers. However, these lasers are less suitable for metallic surfaces due to their low absorption at long wavelengths. Different laser wavelengths can be obtained with lamp- or diode-pumped Nd:YAG lasers (typically Q-switched) or with fiber lasers, which are more appropriate for metallic surfaces. The power of lasers used for marking is generally between 10 to 100 W. Shorter wavelengths such as 532 nm, obtained by frequency doubling of YAG lasers, can be advantageous, but are expensive. For marking metals like gold, which has an absorption spectrum of around 350-416 nm, short laser wavelengths are essential.

Metals

Stainless steel, aluminum, gold, silver, titanium, bronze, platinum, or copper can all be permanently marked.

Lasers have been used for several years now, particularly in engraving and marking metals. It’s not only soft metals like aluminum that can be marked; steel or very hard alloys can also be marked accurately, legibly, and quickly using a laser. With metals such as steel alloys, it’s even possible to implement corrosion-resistant markings without damaging the surface structure using annealing marking. Products made of metal are marked with lasers throughout a huge range of industries.

Plastics

Polycarbonate (PC), Polyamide (PA), Polyethylene (PE), Polypropylene (PP), Acrylonitrile butadiene styrene copolymer (ABS), Polyimide (PI), Polystyrene (PS), Polymethyl methacrylate (PMMA), Polyester (PES).

Plastics can be marked or engraved with lasers through several methods. You can mark many different commercially used plastics with a fiber laser, including polycarbonate, ABS, polyamide, and many more. The finish will be permanent, quick, and high-quality. Thanks to the low set-up times and flexibility a marking laser offers, you can even small batch sizes economically.

Organic materials

Organic materials require only a tiny amount of laser energy to provide them with permanent, clear markings. The experts have developed Laser Marking systems that perfectly address this requirement. Systems whose intensity can be controlled to keep heat generation within the desired limits.

Glass and ceramics

Materials such as glass and ceramics are difficult to safely mark using traditional methods. For this purpose, STYLECNC has developed a technology able to apply high-contrast, crack-free markings to glass and ceramics. Imagine, virtually no breakages or wasted products.

Different laser marking machine processes

Annealing marking

Annealing marking is a special type of laser etching for metals. The laser beam slowly heats the metal causing an oxidation process underneath the material surface, resulting in a color change on the metal surface. Nothing is removed and the surface isn’t damaged, so it’s ideal for applications where rust can build up.

Laser engraving

During laser engraving, the laser beam simply melts the material, and high-pressure gas, usually Nitrogen, is used to blow the molten metal out of the kerf. The impression in the surface is the engraving.

Laser removal

During removal, the laser beam removes any topcoats applied to the substrate. A contrast is produced as a result of the different colors of the topcoat and the substrate. Common materials that are laser marked by this method include anodized aluminum, coated metals, foils, films, or laminates. It can also be used to remove paint.

Foaming

This is used on polymer materials. During foaming, the laser beam melts the material. The melting process produces gas bubbles in the material, which reflect the light diffusely. The marking will then be lighter than the areas that have not been etched. This type of laser marking is used mainly for dark plastics.

Carbonizing

Carbonizing enables strong contrasts on bright surfaces. During the carbonizing process the high-energy laser causes the upper layer of the material to evaporate and oxygen, hydrogen, or a combination of both gases is emitted. Carbon-carbon bonds are formed and what is left is a darkened (carbonized) area.

Carbonizing can be used for polymers or biopolymers such as wood or leather. Since carbonizing always leads to dark marks, the contrast on dark materials won’t be great.

Color engraving

Color engraving is a marking process that uses a MOPA fiber laser source to add color to a metal surface such as stainless steel, titanium, etc. MOPA refers to a configuration consisting of a master laser (or seed laser) and an optical amplifier to boost the output power. The surface is basically stained with the color you want.

3D marking

This is used to mark 3D shapes and objects rather than flat surfaces. An optical expanded beam lens is controlled via a computer in the optical axis direction in a high-speed reciprocating motion. Dynamic adjustment of the focal length of the laser beam creates focal spots in different locations on the surface and keeps the marking uniform and precise.

Source from Stylecnc

Disclaimer: The information set forth above is provided by Stylecnc independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.