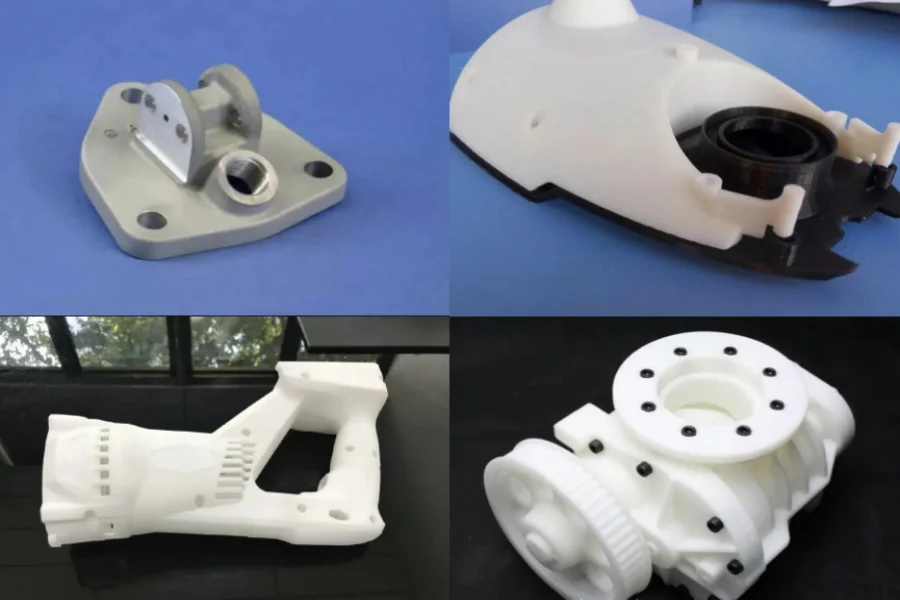

In the production of plastic products, people often have urgent items with short construction periods and high requirements! The traditional plastic molding process goes through many steps (including batching, molding, machining, jointing, decoration, and assembly) to get finished products. If you are in urgent need of high-precision plastic products, try SLA 3D printing technology (also known as stereolithography), which has been widely used in various industries in the manufacturing field because of its characteristics of fast molding speed, high precision, heat resistance, moisture resistance, and wide range of printing shapes: shape and interior decoration of automobiles and scooters; shape and structure design and mold manufacturing of household appliances and communications; rapid manufacturing of toys and shoe molds in the light industry; design of medical devices, surgical simulation and preparation of human bones and joints; design and manufacture of defense weapon parts, precision casting, jewelry, and other industries.

Principle of SLA 3D Printing Technology

1. CAD is used to design a 3D solid model, write a discrete program for slicing a model, and develop a scanning path. The generated data will accurately control the motion of the laser scanner and the lifting platform.

2. Through the reflection of the galvanometer, the laser beam irradiates the liquid-photosensitive resin surface according to the designed scanning path to solidify a layer of resin in the specific area on the surface and process the resin layer to form a section of the part.

3. The printing platform is lifted and lowered for a certain distance. The curing layer is covered with another layer of liquid resin to scan the second layer. The second curing layer is firmly bonded to the previous curing layer so that the three-dimensional workpiece prototype is formed layer by layer.

4. After removing the prototype from the resin, it is solidified and then polished, plated, painted, or colored finally to obtain the required product.

Technical Advantages of SLA 3D Printing

1. UV curing molding is the earliest rapid prototyping manufacturing process with high maturity and has been tested for a long time.

2. The prototype is directly made from the CAD digital model with fast processing speed, short production cycles, and no need for cutting tools and molds.

3. It can process prototypes and molds with complex structures and shapes or is difficult to form by traditional means.

4. It makes the CAD digital model intuitive and reduces the cost of error repair.

5. It provides samples for experiments and can verify and check the results of computer simulation calculations.

6. Compared with the 3D printing molding process of hot-melt materials (such as FDM), SLA molding accuracy is high, and the surface is flat.

While SLA 3D printing technology has been applied in more and more industries, more and more excellent talents and enterprises have joined the 3D printing industry, constantly promoting the development of the 3D printing industry towards more efficiency and convenience.

Anhui Xitai New Energy Technology Co., Ltd. (Xitai New Energy) began to enter the 3D printing industry in 2015 and established a 3D printing equipment production base in Anhui in 2018. It focuses on the R&D, production, and sales of industrial-grade FDM hot-melt molding 3D printing equipment, industrial-grade SLA light-curing 3D printing equipment, and specific metal material 3D printing equipment.

Xitai New Energy has more than thirty software copyrights, three invention patents, and fifteen utility model patents. It has successively passed the certification of ISO9001 quality management system, ISO14001 environmental management system, EU CE safety, RoSH hazardous substances directive, etc.

Its products and processing services are used widely in personalized and customized services such as industrial model mold manufacturing, aerospace special-shaped parts manufacturing, biomedicine, construction engineering simulation, etc. It has significant advantages of high efficiency, high quality, and convenience in the rapid manufacturing service of irregular and complex parts.

Xitai New Energy integrates 3D printing and traditional manufacturing, focusing on actual enterprise production and application services. Adhering to the tenet of Innovation, Development, Focus, and Progress, Xitai New Energy is committed to becoming a high-quality supplier of 3D printing equipment and materials in China. Through 3D printing equipment and products with independent intellectual property rights, comprehensive technology, and technical strength, it provides users with integrated solutions for industrial 3D printing equipment.

3D printing is deeply integrating with traditional manufacturing in value-added creation, gradually evolving along the direction of small and medium-sized batch production and manufacturing and becoming a supplement to the current manufacturing modes.

Source from ofweek.com