Many textile production companies use yarn in their day-to-day activities. The textiles usually come on huge cylindrical spools – or packages – which are wound using a winding machine, a cotton yarn winding machine, or a yarn winder.

Winding machines are not only used for winding textiles but also for paper, film, cord, string, and even rope.

Table of Contents

Market share

Types of winding

Ways of driving in a winding machine

How to select a winding machine

Types of winding machines

Final thoughts

Market share

The cotton yarn winding machine market is big business. Over 70% of this business is held by five global manufacturers, of which Asia is home to around 60%, making it the largest market in the world. In 2020, the global cotton yarn machine industry market size was US $960 million, and by the end of 2027, it is expected to reach US $1042.1 million, a CAGR of 1.2%.

Types of winding

There are different uses for winding machines, and there are different types of winding machines. They Include:

Precision winding

This winding machine windss yarn in close, parallel, and at a decreasing angle ensuring that the yarn is densely packed. However, this type of winding means that the textile is very tightly packed and less stable, making the unwinding process more difficult.

Non-precision winding

In this type of winding, the textile is wound via a single thread at a helix angle to ensure greater stable and less dense. This winding process means that the textile is relatively stable and the rate of unwinding is high.

Ways of driving in a winding machine

Some of the ways of driving in a winding machine include:

Surface contact driving

In this process, the grooved drum comes in contact with the package, which is in turn rotated by a motor. Therefore, when the drum is rotated, the package rotates too. As the diameter of the package increases, the speed remains the same.

Direct package driving at a constant speed

Here, the package is placed in a spindle that is rotated by a motor. The package gets motion directly from the motor, and the rate is directly proportional to the diameter.

Direct package driving at variable speed

In this method, the package is placed on the spindle and rotated by a motor. However, the rotational speed of the package increases according to its diameter.

How to select a winding machine

Weight of coil

The dimensions of the coil, together with its weight, need to be considered when choosing a winding machine. If the coil weighs more, the speed at which it rotates on the package will be reduced and vice versa. It is essential to have a machine that can hold the coil’s weight.

Wire diameter (0.01-4.5mm)

Wires have different diameters, and these affect the winding process. Larger wire diameters mean longer rotation times, thus reducing the winding speed and increasing production time.

Coil dimension

A winding machine must use a compatible coil for that specific machine i.e. if the machine is designed for a large coil dimension, the wire must also be of a large dimension. Therefore, you must also consider what coil dimension you require prior to purchase.

Coil winding method

When choosing a winding machine, the method used to wind the coils must also be considered, adjusted according to the desired rate of production. Coils can either wind at high speed with low torque or at a low speed with high torque.

Types of winding machines

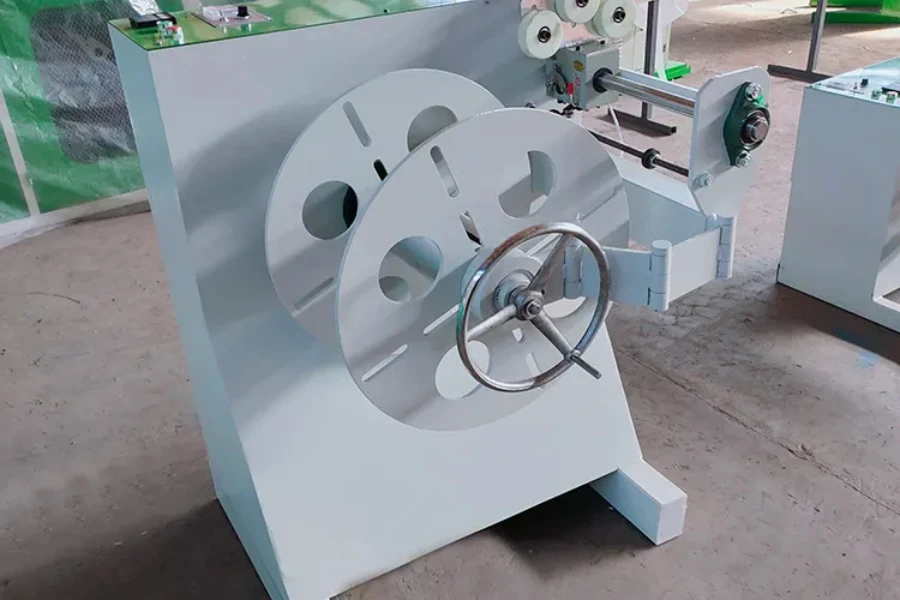

Spool winding machines

A spool is a cylindrical device on which flexible materials can be wound. A spool winding machine rolls material, mostly yarn, into spools using a high-speed inflow twister. This high-production machine can twist the twine and spool at the same time.

Paper winding machines

A paper winding machine is used for rolling various types of paper and cardboard, such as baking paper, silicon paper, gift wrap paper, and wax paper. It can wind the paper without needing a core to hold the roll together and has a magnetic powder system that accurately controls the length of the spool.

Film winding machines

A film winding machine can wind or stretch or cling film-type materials and divide them into smaller finished rolls. It is an automatic machine that loads and changes the paper core, cuts and loads the finished product, and slices and banks.

Rope winding machines

Rope winding machines are used to wind different types of rope, including materials such as cotton, manila, nylon, sisal, and even synthetic hemp. They are high-production machine and easy to maintain, using a length counter and automatic stop to set the spool’s length. Each machine has a different motor depending on the type of material that is used.

Foil winding machines

A foil winding machine is a machine that is specially designed for winding foil coils that are used in reactors. Highly automated, they usually wind copper or aluminum into oval, rectangular, or circular shapes. The head and tail chuck are interlocked in order to ensure a matching winding motion.

Final thoughts

There are many types of winding machines used across several types of textile industries. For a business to be profitable, the right winding machine must be selected for the specific purpose. Visit Alibaba.com to browse the winding machines mentioned above.