Wood chippers, also known as tree chippers, are machines that cut tree limbs, trunks, and branches down into small, manageable chips. They are also used to dispose of leaves, branches, and hedges, turning them into leaf molds and composts.

Table of Contents

Market share

Types of wood chippers

How to choose a wood chipper

Benefits of using a wood chipper

Final thoughts

Market share

The wood chipper industry’s market value stood at US $387.4 million in 2019, and is forecast to have compound annual growth rate of 2.3% from 2022 to 2027. This growth is largely due to the cutting down of trees and shrubs to make way for urbanization of rural areas worldwide, coupled with an increase in demand for wood across many industries, including those that relate to furniture, paper, and pulp.

Types of wood chippers

There are a few types of wood chippers available for commercial or domestic use. They include:

Electric wood chippers

Quiet and emission-free, electric wood chippers require less maintenance, use less power, and can be used within the convenience of the garage or anywhere with a nearby power outlet. They are ideal for when you only need a chipper for the occasional clean up of the garden, with the only real disadvantage being that it’s restrained by the length of the cord.

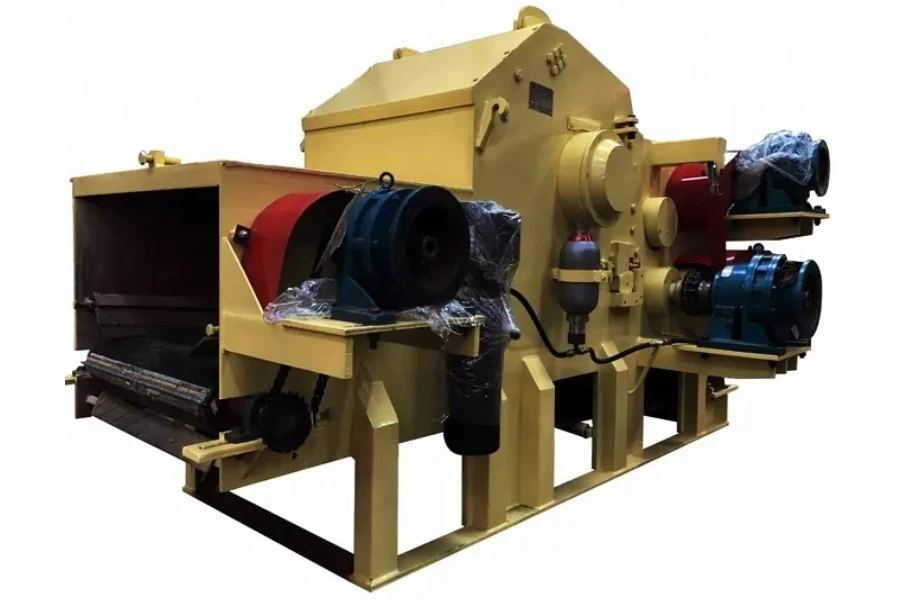

Drum wood chippers

Drum wood chippers are named for the large drum found on their side. Inside is lined with horizontal knives that chip the feed. These chippers work quickly to get rid of huge chunks of waste wood, depositing them out of a shoot for easy clean up.

Petrol wood chippers

Petrol wood chippers, as the name suggests, use petrol to run. They are often more powerful than their electric counterparts, making them ideal for heavy-duty chipping tasks. However, their superior speed, strength, and mobility is often reflected in their price, though they can also be noisier.

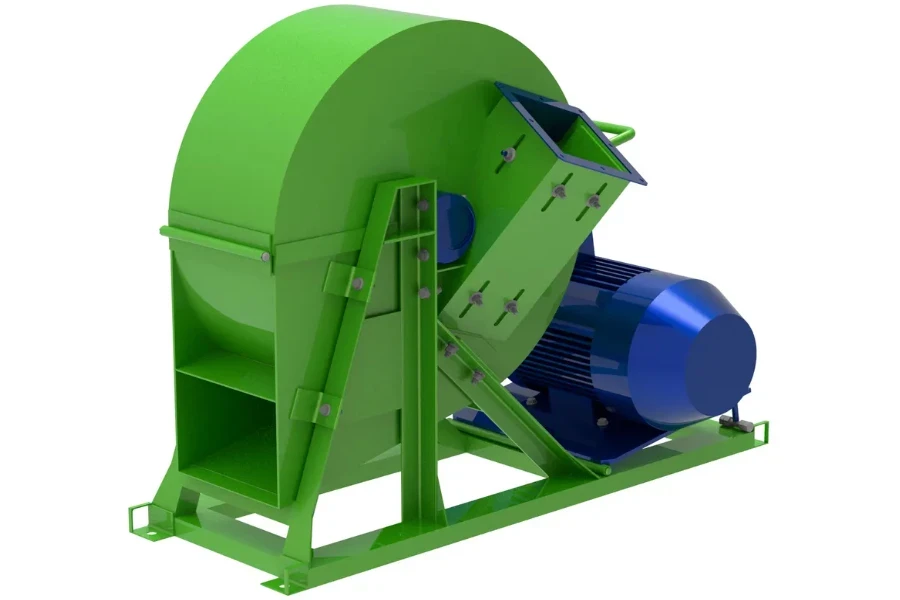

Screw chippers

Screw wood chippers are quite common and have varied designs. These types of chippers use a conically-shaped blade that rotates and cuts easily through the feed. Because the blade rotates parallel to the opening, the spiral motion pulls the wood in before depositing out of an elevated shoot, doing the hard work for you.

Disc chippers

Disc wood chippers are considered the original chipper design. Its chipping mechanism is made up of blades mounted on a steel disc, and its rotational design makes them best suited for long logs, cut-offs, and slabs. Disc chippers produce uniform chips.

How to choose a wood chipper

Some factors to consider when choosing a wood chipper include the following;

Feed capacity

The feed capacity is the limit of wood that the chipper can chip. Smaller machines can only chip pieces with a small diameter, while commercial-sized chippers can chip larger pieces. Your decision as to which you need will be dependent on the type of wood you need chipped.

Power

The horsepower of the wood chipper chosen should be able to produce the needed chips. This mainly depends on the kind of wood being chipped and the chipper’s drum.

Required storage

It is essential to consider how you intend to store your chipper, as inferred by available storage space. Chippers come in a variety of sizes: some are big, bulky, and approaching the size of trucks, while others are smaller and more mobile – think the size of a desk.

Spare parts

When purchasing any machine, whether a car or wood chipper, it is essential to consider your access to spare parts. Wood chippers are costly, and after heavy use, the parts can wear out, therefore, it’s important that you can source spare parts easily if and when needed.

Blade quality

The chipper blade is arguably the most important part of the machine as it’s the part that gets the work done. If the blade is of poor quality, you’ll get poor-quality chips and a subpar chipping experience overall.

Clearance size

The amount of chips or pulp to be cleared after you’re done chipping is also an important factor to consider. Your machine needs to be able to clear what you ask of it, and failure to do so will obviously be a huge loss and a waste of time.

Benefits of using a wood chipper

Finally, some of the benefits of a wood chipper include:

They promote recycling

Wood chippers often create mulch that can be used to nurture and protect plants without using additional fertilizers. Therefore, they make for an excellent money-saving way to dispose of materials that would otherwise end up in a landfill or be burned, producing toxic emissions and posing a potential fire hazard.

They make materials easy to transport

Tree discards can often be particularly hard to transport, therefore, wood chippers excel in helping to make waste materials more manageable.

They quickly remove unwanted waste

Chipping wood is an easy and fast way to clear waste, simply by chipping waste materials and then reusing them.

Final thoughts

Wood chippers are helpful tools, especially when you have an excess of tree limbs or other natural materials you need to dispose of. If you are looking for a great selection of the latest models, including all of the varieties listed above, look no further than the extensive range on Alibaba.com.