Table of Contents:

What is a fiber laser cutting machine

What is a fiber laser cutting machine used for

Where are fiber laser cutting machines used

What are the parts of a fiber laser cutting machine

What is the working principle behind a fiber laser cutting machine

How to define the cutting quality of a fiber laser cutting machine

Safe operation of a fiber laser cutting machine

Daily maintenance of a fiber laser cutting machine

How to buy a fiber laser cutting machine from STYLECNC

1. What is a fiber laser cutting machine?

A fiber laser cutting machine is a machine that creates a laser beam from optical fibers, focuses it into a high-power density laser beam, and transmits it to the machine’s cutting head. The super-hot laser beam can melt and pierce metals and a high-speed airflow that’s parallel to the beam blows away the molten pieces. Pretty cool right?

By moving the beam and the workpiece, you can cut steel and other materials with amazing accuracy.

So basically, imagine a laser cutting material instead of a knife. It’s really precise and fast and isn’t limited to cutting pattern restrictions. This is great because it saves material by automatic typesetting, the incision is flat and smooth, and its processing costs are low. It’s so easy and efficient it’s gradually going to improve or replace traditional metal cutting process equipment. The laser cutter head doesn’t come into contact with the workpiece, so no scratches like traditional methods, and. no subsequent processing is required either.

Here are some more benefits; The heat-affected zone and plate deformation are very small and the slit is narrow (0.1mm~0.3mm), therefore, no mechanical stress and no cutting burrs on the notch. High precision machining with good repeatability and no damage to the material surface. Can be NC programmed, can process any plan, and can cut a whole board with a large format without an open mold. On top of all that it’s economical and time-saving.

2. What is a fiber laser cutting machine used for?

Fiber laser cutting machines can cut all kinds of metal materials such as:

Iron

Alloys

Brass

Copper

Titanium

Aluminum

Carbon steel

Structural steel

Stainless steel

3. Where are fiber laser cutting machines used?

Fiber laser cutting machines are used for lots of different tasks in various industries and are now a piece of equipment that loads of businesses can’t live without. Here are some examples of industries that use laser cutters;

Advertising

Sheet metal processing

Chassis cabinet production

Spring sheet production

Subway parts

Elevator manufacturing

Kitchen and kitchenware manufacturing

Fiber laser cutting machines are widely applied in sheet metal processing, advertising sign making, high- and low-voltage electrical cabinets manufacture, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, eyewear industry, spring sheet, circuit boards, electric kettles, medical microelectronics, hardware, knife measuring tools, and lots more.

4. What are the parts of a fiber laser cutting machine?

They consist of three main parts:

The first one is a heavy-duty frame which is normally welded with tubes and sheet metal. This increases the cutter’s longevity, as well as being able to be used for spirit level measurement (Figure 4-1) to make sure the work is precise. Very handy! It is also used to position the workpiece to be cut and it can be moved accurately and precisely according to the control program. It is usually driven by a 2pcs servo motor (Figure 4-2).

The second part is the beam transmission system. This includes all the transmission optics and necessary mechanical components to emit the beam from the laser generator (Figure 4-3) to the workpiece.

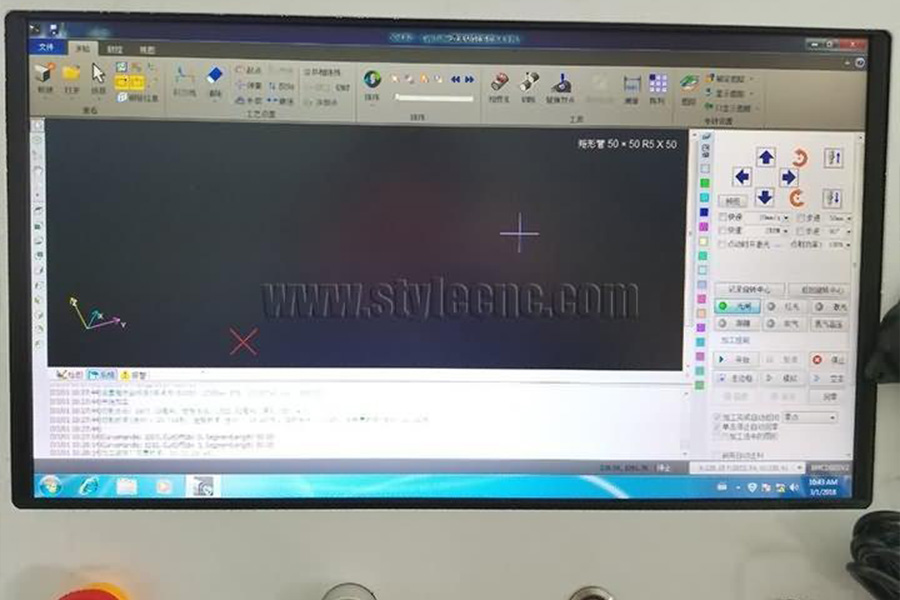

The final part is the CNC control system (Figure 4-4). This allows movement of the X, Y, and Z-axis so it’s super versatile. It also controls the generator output power.

As well as these three important parts, there are also other fiber laser cutting machine parts worth learning about.

A. The outside light path

This refers to the refractive mirror which directs the laser where you want it to go. To prevent the beam path from being broken, all mirrors are protected by a protective cover, and a clean pressurized protective gas is introduced to stop the lens from being contaminated. A set of high-quality lenses focus the beam precisely onto an infinitely small area. A 5-inch focal length lens is generally used but 7.5-inch lenses are needed for materials more than 12mm thick.

B. Stabilized voltage supply

This connects the laser generator, frame, and power supply system. It must be stabilized to prevent any interruption of the external power grid and protect the machine from power surges.

C. Fiber laser cutting head

This is made up of several parts including the cavity, focusing lens holder, focusing lens, capacitive sensor, and an auxiliary gas nozzle. The cutting head driving device drives the cutting head along the Z-axis direction according to a program and is composed of a servo motor, a screw rod, or a gear.

D. Water chilling system

This stops the laser generator from becoming too hot (Figure 4-5). A laser is formed by converting electrical energy into light energy. For example, a fiber laser usually has a conversion rate of more than 25%, and the remaining energy is converted into heat. Cooling water removes any excess heat to keep the laser generator working in cold water. The unit also cools the machine’s external light path mirror and focusing lens to maintain stable beam transmission quality, and effectively prevents the lens from overheating which would cause deformation or even bursting.

E. Gas (Figure 4-6).

There are 4 reasons gas is needed. The assist gas reacts with the metal to increase the working capacity. Gas is used to blow away the molten slag, Auxiliary gas cools the area around the cut which stops the material shape from being changed, and most importantly, gas prevents the focusing lens from being damaged by the high temperature of the laser beam. Different gases are used, depending on which metal is being cut.

F. Other equipment for daily use

Air compressor, filter, exhaust fan, etc.,

5. What is the working principle behind a fiber laser cutting machine?

A laser stimulates atoms or molecules to emit light at particular wavelengths and amplifies it, producing a very narrow beam of radiation. Did you know LASER stands for ‘light amplification by stimulated emission of radiation’?

However, unlike ordinary light, laser light (Figure 5-1) is only dependent on spontaneous radiation for a very short time. Since the process is completely determined by one wave of excited photons, the laser has a very pure color, minimal light divergence, high intensity, and high coherence.

Fiber laser cutting is achieved by applying a high-power density laser beam generated by laser focusing. A computer controls the laser to discharge pulses to output a controlled repetition of a high-frequency pulsed laser to form a beam of a certain frequency and pulse width. The pulsed laser beam is conducted and reflected by the optical path and focused by the focusing lens. A subtle, high-energy density light spot is formed on the surface of the workpiece. The focal spot is located near the surface to be processed, and the processed material is instantly melted or gasified at a high temperature. Each high-energy laser pulse instantly sputters a small hole in the surface of the object. Under the control of the computer, the laser processing head and the material to be processed are successively moved and plotted according to a pre-drawn pattern, so that the object can be processed into the desired shape.

6. How to define the cutting quality of a fiber laser cutting machine

How do you know whether a CNC laser cutting machine is of high quality? Well, it depends on four factors, and it’s all about cutting accuracy.

A. The laser generator cohesion size. Following cohesion, the cutting precision will be extremely high if the laser beam is very narrow. The gap will be very small after cutting too. This means that the cutting quality and cutting precision are particularly good.

If the laser generator is wide, the cutting gap will also be wide. In this case, the thicker the workpiece, the bigger the gap.

B. The precision of the frame. Before working, each part of the frame should be checked. The vertical and horizontal parts of the frame must be perfect. If there’s only a 0.1mm deviation of each part, this will get bigger and bigger when the machine is in operation.

C. The shape of the laser beam. If the beam from the laser generator is tapered, the cutting gap will also be tapered. So, the thicker the workpiece, the bigger the gap.

D. The cutting quality is also affected by the material being cut. For example, under the same conditions, there’s a big difference when cutting stainless steel and aluminum. For cutting stainless steel the precision and cutting edge will be much better than for aluminum.

Generally speaking, the fiber laser cutting machine can be defined by the following 5 standards.

A. The quality of the cutting edge.

B. The size of the cutting edge slag.

C. The trimming, both perpendicularity and inclined.

D. The cutting edge fillet size.

E. Flatness.

7. Safe operation of a fiber laser cutting machine

Users must be trained by professionals before operating laser cutting machines independently. Based on our experience, here are 13 ways to ensure the safe operation of a fiber laser cutting machine.

A. Read the safety rules that come with your machine. Read all instructions first and start the laser strictly according to the laser start-up procedure.

B. Familiarize yourself with the machine structure and parts, and learn the operating system procedures.

C. Wear protective glasses or a visor when using the fiber laser beam.

D. Check beforehand if your material is suitable for cutting with a fiber laser otherwise it may produce smoke and be a safety risk.

E. When operating, never hand it over to others who aren’t trained, or leave it running. If you need to leave, turn off the machine.

F. Keep a fire extinguisher nearby. Turn off the machine when not in use. Don’t keep paper, leather, or other flammable materials near the laser cutter.

G. If there are any operating problems, stop the machine immediately and troubleshoot, or inform qualified engineers.

H. Keep the laser, frame, and surrounding area clean, orderly, and free of oil. Keep workpieces, metal sheets, and any scrap stacked tidily.

I. When using gas, be careful not to squash or pinch the welding wires to prevent leakage accidents. Always comply with recommended gas cylinder monitoring procedures. Don’t expose cylinders to sunlight or heat sources. When opening the bottle valve, always stand to the side of the bottle connector.

J. Observe high-pressure safety regulations when servicing. Keep to maintenance schedules, such as servicing after every 40 hours of operation or weekly, and every 1000 hours of operation or every six months, whichever comes first. Perform all maintenance in accordance with the regulations and recommended procedures.

K. After switching on the machine, manually start the machine at low speed in X and Y directions to check for any abnormality.

L. After a new part program is entered, it should be tested, and its operation checked.

M. When working, pay attention to the position of the machine frame to avoid the machine getting out of the effective range or two machines colliding and causing accidents.

8. Daily maintenance of a fiber laser cutting machine

The frame (Figure 8-1)

A. Before starting the machine, carefully check the laser working gas and cutting gas pressures. If the gas pressure is not right, replace the tank promptly.

B. Check if the X-axis zero point, Y-axis zero point, Z-axis zero point, or laser preparation status, etc., are damaged (check indicator).

C. Check for any looseness of the zero point, X-axis, Y-axis, and Z-axis limit switches, and the screws in the impact block, and whether the limit switch of each axis is sensitive.

D. Check whether the circulating water level in the chiller is sufficient. If not, top it up before operating the machine.

E. Check for any leakage in the external light path circulating water circuit. Leakage must be fixed straight away, otherwise, the life of the optical lens is affected.

F. After finishing cutting, check the lens of the focusing lens for damage.

G. Check whether the outer light path bellows are burned or damaged.

H. After finishing work, clean up the cutting waste and the working area, and keep the area tidy and clean. Thoroughly clean the equipment to ensure that all parts are clean and free of dirt.

I. After switching the machine off, open the air reservoir drain valve at the bottom of the air compressor and close it after the wastewater is discharged.

J. Before leaving, press the shutdown button to shut the machine off and turn off the power to the entire machine.

WEYO

The laser generator (Figure 8-2)

A quick daily check of the laser generator is vital before starting up the machine too:

1. Check the cooling water pressure is between 3.5-5 Pa.

2. Check that the temperature of the cooling water is the required temperature required for your laser generator.

3. Check the oil level in the laser generator vacuum pump. If too low, top it up to the correct level.

4. Check for any leakage from the oil, water, and gas lines of the laser generator, and whether the vacuum pump or the pneumatic components in the resonator are leaking.

9. How to buy a fiber laser cutting machine from STYLECNC

A. Consult: the most suitable fiber laser cutting machines will be recommended to you after we discuss your requirements, such as the metal materials you want to cut and the maximum size of the metal materials (length x width x depth).

B. Quotation: We will happily supply you with a detailed quote for your recommended machine, including the best quality and most competitive price.

C. Process evaluation: We will carefully evaluate and discuss all the details (including technical parameters, specifications, and business terms) to get it right for you, and prevent any misunderstanding.

D. Placing Your Order: You will be sent a PI ( Proforma Invoice) before both parties sign a sales contract.

E. Production: We will arrange production as soon as we receive your signed sales contract and deposit and will keep you updated during production.

F. Quality Control: The whole production process is subject to regular inspections and extremely strict quality control. The completed laser metal cutting machine will be tested thoroughly before leaving the factory.

G. Delivery: We will arrange delivery as previously agreed after confirmation from the buyer.

H. Customs Clearance: We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance process.

Source from Stylecnc

Disclaimer: The information set forth above is provided by Stylecnc independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.