Like all other industries, the food industry is constantly changing. The trends can be straightforward or complex, covering everything from how the facility operates to how the food is prepared. Industries experience growth, can scale, and produce better results when they adopt cutting-edge technologies. Discover the latest developments in this space and take measures accordingly.

Table of Contents

An overview of the food machinery market

Top developments in the food machinery sector

Innovative solutions for long-term success

An overview of the food machinery market

The global food processing market was valued at USD 45.01 billion in 2019 and is projected to reach USD 62.98 billion by 2027, showing a CAGR of 4.4%. The food manufacturing and processing equipment are semi-automatic and automatic; however, there is an increasing demand for the latter. This is because it is efficient, saves time and money, and has a high production capacity.

The rising demand for processed foods such as poultry, meat, and bakery items, among others, is driving the machinery market. Furthermore, the expansion of food manufacturing facilities in Asia and Africa has fueled the growth of the food processing machinery market. Scroll further to explore the eight trends shaping the food processing industry.

Top developments in the food machinery sector

Increased dependence on automation and IoT connectivity

Although the food industry has a history of being conservative in adopting new technology solutions, updating to new technologies will be a priority. The implementation of new tools in the industry will continue to grow as these processes increase productivity, optimize workflow, improve margins, and remove existing barriers.

As the food industry is experiencing a significant labor shortage in the wake of the pandemic, there will be an increased shift toward automation. This shortage has put pressure on technology solution providers to devise innovative strategies for providing quality customer service while employing fewer people on-site. The role of robotics will be critical in mitigating labor shortages and increasing efficiency.

More businesses are embracing robotic technology as the cost has fallen slightly since 2018, and the ROI has made a lot of financial sense. The pandemic accelerated automation growth, with robotic orders increasing by 56% in 2020 over the previous year. For the first time in history, a non-automotive sector outpaced the automotive industry in terms of orders. However, the costs remain high and are still the most significant barrier to full-scale implementation.

Cobots: Cobots, or collaborative robots, are the newest trend in food industry automation. They are inexpensive and convenient because they do not use industrial-level electricity. They are also in high demand, with most of those planning to buy robots choosing a cobot. These machines boost productivity, improve worker safety, and lower operating costs. They can also be programmed to perform various tasks, such as processing, packaging, and distribution.

Machine vision: Machine vision is another popular automation tool that uses lasers to verify packaging dimensions. This technology can also perform quality assurance to detect issues such as open or irregular packaging. If the machine vision detects such issues on a line, the item will be moved to another line and thus will not go out for delivery. This technology offers quick, efficient, and reliable solutions.

Innovative drainage systems

Improved safety and sanitation are always top priorities in food and beverage processing facilities. Modern drainage systems provide advanced sanitary solutions to prevent standing water and bacteria growth. The latest drain system is made of durable, food-grade stainless steel, making it resistant to temperature, corrosion, odor, and bacteria.

Modern drainage systems are also built to withstand heavy forklift traffic and high flow rates. The best part is that slot drains are easy to clean and maintain because they have automated cleaning options.

Updating outdated processing techniques

The food industry can never abandon tried and tested processing techniques, so they are constantly updating and modernizing them. Fermentation is one process that has seen a significant revival due to the high demand for fermented beverages and foods.

The ancient fermentation method involved mixing fruits with salt and wild rice in containers and leaving them to ferment in small batches. This process was refined over time to eliminate undesirable ingredients.

With precision temperature controls, cutting-edge analysis tools, and other devices, technology is now making large-batch fermentation simpler and faster, helping to meet the growing demand while prioritizing safety and quality.

Food waste reduction

Because a large portion of food produced globally is lost or wasted, reducing food waste is a pressing issue in food service industries. Large corporations are looking for ways to make food waste reduction a standard operating procedure, lowering costs and reducing environmental impact.

Food monitoring systems will help producers and restaurants keep track of their inputs and cut down on food waste. Others focus on zero-waste solutions—businesses look to reuse food waste to generate value and increase customer interest in sustainability. 3D food printing solutions, for example, use food waste to print edible food products in food joints and restaurants.

An increase in plant-based products

In the last 15 years, plant-based diets have increased by 300% in America, and plant-based products are expected to grow in popularity in the coming years. The global retail market is projected to grow from USD 29.4 billion in 2020 to USD 162 billion by 2030.

As consumer preferences evolve, manufacturing technologies will need to adapt as well. While many companies have implemented solutions to meet the growing demand for plant-based foods, new techniques are needed to develop and process foods efficiently.

Furthermore, culture-based proteins, while not yet mainstream, are gaining traction and are an excellent plant-based protein alternative.

Sustainable and smart packaging

As more people become concerned about climate change, there will be greater demand for products that leave minimal footprints. Many manufacturers are responding by becoming more eco-conscious and aiming to replace fossil-fuel-derived energy with renewable energy.

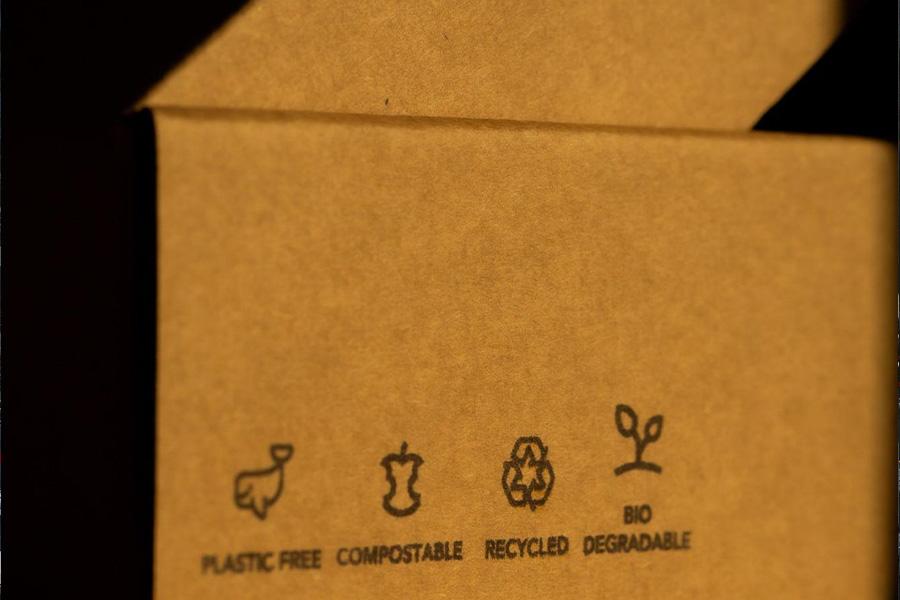

One trend that will continue to grow and expand is sustainable packaging, where the preference will be to reduce plastic and replace it with recyclable, biodegradable alternatives.

Many EU countries have banned single-use plastics, and others will follow suit gradually. Some businesses provide edible packaging made from food-grade polymers, such as seaweed that is safe for consumption. On the other hand, biodegradable packaging is made of polymer-derived plastic that degrades naturally over time.

Nano packaging is the most recent type of smart packaging, which uses nanotechnology to detect microbial changes in foods. This technology is used to determine whether the food is safe or at risk of spoiling.

Forward osmosis

Concentration techniques are used to keep foods fresh enough till they reach consumers. The CSIRO organization in Australia has developed a new preservation technique that uses membrane technology to concentrate liquids in a process known as forward osmosis.

Forward osmosis is a gentler process that concentrates foods with less energy and no heat. This helps the food retain its nutrients, such as vitamins and proteins, throughout the manufacturing process. When compared to traditional concentration methods, this results in higher-quality products.

Transparency and advanced food safety

There have been numerous cases of food-related recalls in recent years, particularly for poultry, meat, and lettuce, for reasons such as E. coli and other safety concerns. Because these staple food items have been repeatedly recalled, consumers and manufacturers have a sense of uncertainty and distrust. To challenge these notions, many companies are transparent and directly address the consumers about what is going on with their products. Open communication is paramount in gaining consumers’ trust and respect.

Innovative solutions for long-term success

Each year, food technology evolves, having a significant and long-term impact on the market. Sustainability innovation will grow in tandem with automation and waste reduction practices.

Furthermore, labor shortages will pave the way for robots, resulting in durable changes in food manufacturing and retail.