A rice mill is a unique facility where raw paddy is processed into rice. Rice mill machines are used in the rice milling process to remove any impurities in rice with ease. There are many types of rice mills available in the market today, which can make it hard to identify the best option. Nonetheless, it is important to buy the right machine as that will determine the quality of the final product.

So read on to learn about the market potential for rice mills, as well as the different types of rice mills available and how to select the right one.

Table of Contents

Market share for rice mills

Types of rice mill machines

Your guide to selecting rice mills

Summary

Market share for rice mills

The major players involved in the rice milling machinery market have invested in developing the technological components of the machines. This move has focused on reducing the size of the equipment while increasing efficiency. The healthy competition among these producers has led to the growth in demand for rice milling machinery. Some of these manufacturers include AG Growth International Inc, Satake Corporation, Fowler Westrup, and Yamanoto.

A report by Future Market Insights values the global milling machine market at USD 1,176.43 million in 2023. There will be further expansion at a compound annual growth rate (CAGR) of 2.3% to reach USD 1,476.81 million by 2033. This is due to the rapidly growing rice market which will in turn result in an increase in demand for rice milling machinery.

Regionally, China, Japan, the UK, and South Korea are expected to register significant market share values of USD 275.72 million, USD 76.47 million, USD 64.70 million, and USD 48.33 million respectively. Their respective CAGR up to 2033 will be 9%, 9.5%, 5.1%, and 10.6%. Considering the product type, the horizontal roller segment holds the largest market share and will grow at a CAGR of 2.9%. Additionally, based on application, the pre-cleaning equipment has the highest market share and will expand at a CAGR of 3.3% during the forecasted period.

Types of rice mill machines

1. Fraction-type rice milling machine

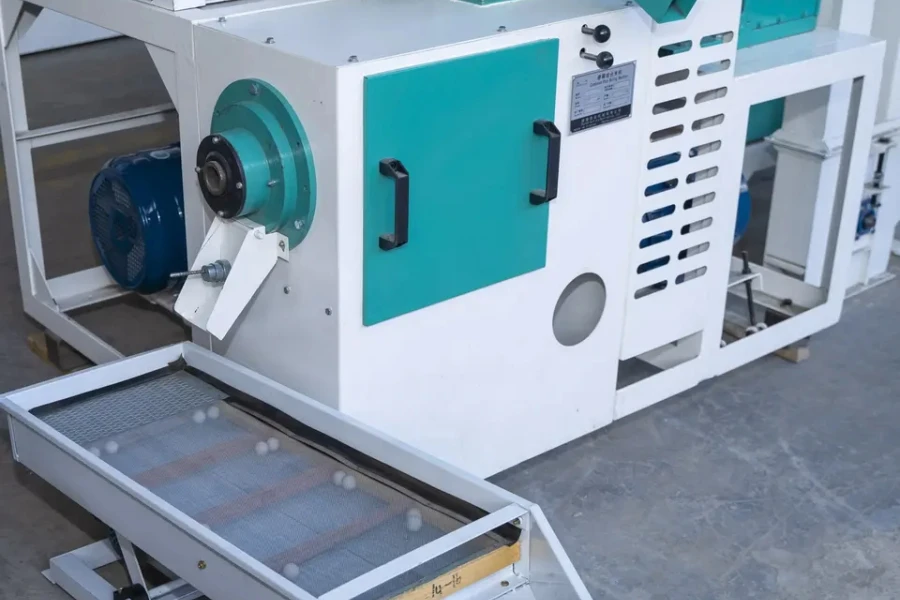

The fraction-type rice milling machine relies on the strong friction of an iron roller to process brown rice into white. It is also commonly referred to as a pressure-type rice milling machine. The machine processes rice by the action of advancing and flipping off the iron roller. This movement causes strong collision, squeezing, and friction between rice particles. Then in the whiting chamber, there are components that separate the endosperm and cotyledon of brown rice to attain white rice.

2. Grind rice milling machine

The grind rice milling machine removes the bran layers by grinding and cutting rice grains using the emery roller at high speeds ranging from 10 to 16 grains per second. This results in lower rice breakage and increases the output of white rice. There are two types of rice milling machines: vertical and horizontal types.

Your guide to selecting rice mills

1. Cost

Buyers should begin by determining the approximate cost of setting up rice mills. The cost is dependent on various factors like the level of technology, capacity, raw materials, land availability, and personnel hired. Generally, simple rice millers are the most common due to their affordability and cost-effectiveness. The average price for simple rice processing machines is approximately USD 500. On the other hand, there are more advanced rice millers for large-scale and commercial purposes that cost more. This is because they offer more features like minimized rice breakage. Their average cost starts as low as USD 700.

2. Production rate

The production rate of the rice milling process depends on the performance of the processed rice recovery and quality. This is also referred to as the milling potential which is affected by the type of rice, pre-milling processes, and the quality of the rice. For polished white rice, the machine milling rates average about 72% of rough rice weight. Most rice millers produce about 20% byproducts of rough rice weight. These include broken rice and rice hulls. Rice germ averages about 8%. Buyers should opt for the most efficient rice millers that ensure the highest rice quality.

3. Power equipment

The rice milling industry uses various types of energy to produce power during rice processing. These energy sources include thermal, mechanical, electrical, and human energy. Electricity is the main source of power used to run rice millers. Some of the components that require power include boilers, pumps, blowers, motors and transmission systems. Buyers should select rice millers that use easily available power. The machines should consume less power while producing quality rice. Modern rice milling equipment is estimated to consume an energy of about 9.54*10^5 J/kg. This energy consumption results in a broken husks percentage range of 10-20%.

4. Execution type

The execution type divides the rice milling machines based on their mechanical milling properties. The two types include grind rice and fraction-type milling machines. The fraction-type rice miller uses the friction of the iron roller to produce white rice. On the other hand, the grind rice miller gets rid of the bran layer by cutting and grinding the rice grains. Grind rice milling equipment is faster than fraction-type rice millers. It has a roller line speed of about 15 m/ sec which results in less broken rice. Notably, these machines can easily grind rice with harder layers as compared to the fraction-type rice milling equipment.

5. Speed

Considering the speed of rice milling machines, an engine rotation speed of 1,237 rpm gives an average stripping efficiency of 46.3%. This determines how fast the rice grain cortex is ground, divided, peeled and eventually whitened. Buyers should know that an optimum speed rice milling machine will produce about 50-72% head rice (whole kernels), 5-10% large broken, and 10-15% small broken kernels. Also, sometimes, the slow speed of rice milling may be due to dirty rice.

Summary

The rapid upgrades in agricultural machinery have made machines that deal with rice processing more advanced. As a result, buyers need to know the basic functionality of rice milling machines. This will greatly help them in the choice of the most appropriate rice milling equipment for their production lines. The above guide outlines the essential considerations to be taken into account by buyers when investing in the most suitable rice milling machinery. To read more, or to acquire high-efficiency rice milling equipment, visit Alibaba.com.