Considered an innovative industrial technology, 3D printers have impressive global market potential. This is because visual graphics and design play key roles in most business campaigns and presentations, which contributes to the rise in global demand for 3D printing.

In 2021, 3D printers gained an annual market value of over USD 13.84 billion globally, and some forecasts show an estimated 20.8% compound annual growth rate (CAGR) from 2022 to 2030. China is currently one of the largest 3D printing markets, but the USA remains the largest base for 3D printers worldwide. While other countries like the UK, France, Germany, South Korea, and Australia continue to invest and drive growth in this industry.

Given the immense value 3D printers offer, this guide will highlight some key factors to consider with regard to 3D printing market opportunities, before giving a summary of the best 3D printers available on the market today.

Table of Contents

What is a 3D Printer and what is it used for?

Is 3D printing hard?

How long does a 3D Printer take?

Can you start a business with a 3D Printer?

The best 3D Printers to buy?

3D Printers target market

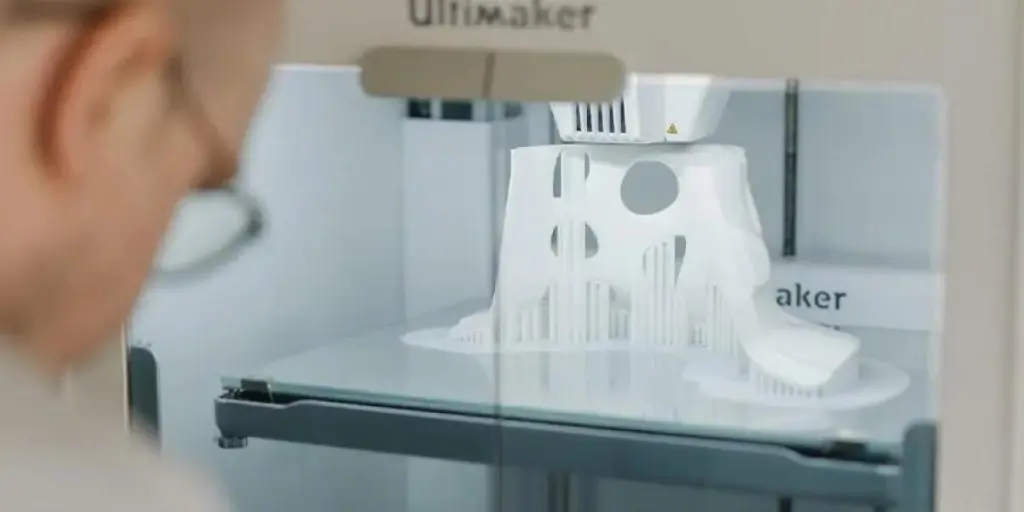

What is a 3D Printer and what is it used for?

A 3D printer is a device that uses computer designs to form shapes and objects. The formation process is achieved by the addition of different layers of material, which continuously build up until a fully realized structure is formed.

3D printing has a wide range of applications and is very useful across many industries like the robotics, aerospace (and astrospace), medical, automotive, and rail industry. Similarly, the technology is commonly utilized in the creation of advertisement materials, prototypes, waxed items, and market products (like toys, shoe designs, phone cases, mugs, etc).

Is 3D printing hard?

A 3D printer with user-friendly features like a touchscreen interface, safety system, easy refilling design, and smart control keys should be easy to operate, for both beginners and experienced operators. However, 3D printing machines with complex set-up processes may seem difficult, particularly for beginners due to their technical complexity —like the operation of the hardware and software systems. However, hands-on training can prepare a user for the technical requirements of a 3D printing machine model.

How long does a 3D Printer take?

A fully functional 3D printer creates a finished 3D object in anywhere from 30 minutes to 24 hours, depending on the size and complexity of the machine model. However, certain 3D printers can take as much as from 3 to 7 days or more to complete one printing cycle. Other factors like the machine’s printing technology and the geometry of objects to be printed can influence the printing time.

Can you start a business with a 3D Printer?

Most innovation-driven businesses are continuously searching for printing experts who can bring their brand vision to life, and this is why the printing business will remain relevant in the mainstream market. So with the right equipment and skills, one can build a successful 3D printing business.

Below are some of the ways to make money through 3D printing

- Offering 3D printing services within your local area.

- Printing innovative marketing products for businesses.

- Selling pre-made 3D printed items on online marketplaces like Etsy.

- Renting out your 3D printed products, and of course there are many more.

The best 3D Printers to buy?

1. Top 3D printer for glass bottles, wood, metals, mugs and phone cases

This is a fully mechanized UV printer programmed to print various kinds of material, whether plastic, leather, wood, acrylic, metal, ceramic, glass, textile, or fabrics. The machine has a built-in auto-cleaning and auto-keep wet system. The high-speed UV printer has up to 3 printheads and can print large objects, up to 40 x 30cm to 100 x 160 cm. The machine utilizes UV-resistant materials like Polycarbonate + Acrylonitrile Styrene Acrylate Alloy, ASA filament, and PETG. This unique printer is capable of creating an embossing 3D effect on any item. It also has an integrated rotary printing device that allows it to form round and spherical objects like mugs or bottles, with a rotary print height of 8 cm to 18 cm.

Features:

- Has 3 print heads that enables the device to print complex patterns

- Has a dual hi-win linear guideway on X-axis

- Auto print head lock is readily available

- Designed with full aluminum suction platform that is equipped with strong air fans (for corrosion and scratch control)

- Has tight tolerances advantage

- Offers a 13 months warranty and lifelong technical support.

Price range: $206.32 – $4,835.11 (has a printing cost of $1 per 1 square meter item)

Pros:

- Offers better printing accuracy.

- Offers longer machine lifespan.

- Offers swift movement and smooth surface finishes.

- Has an anti-corrosion and anti-scratch design.

- Has auto-cleaning and an auto keep wet system.

- Capable of printing complex shapes.

- Offers easy and cheap maintenance.

Cons:

- They are not eco-friendly due to the UV rays.

- Requires close monitoring due to its high-precision rate.

- Some of the material needs to be pre-coated (materials like metal, glass, acrylic etc) to make the color anti-scratch.

- The machine spare parts and ink can only be purchased from the supplier.

2. Top extruder 3D printer

The extruder 3d printing machine is a high-flow filament printer known for its quality printing and extruding powers. It comes complete with cutting-edge designs such as auto leveling, filament sensors, nozzle anti-collision, and more. This machine type is great at producing high-quality extraction and is independently controlled. It has a 200mm/s speed rate and uses filament (materials) such as PLA, PETG, and PBT for its printing process.

Features:

- Great nozzle design with anti-corrosion ability.

- Good filament sensor and auto-leveling ability.

- Highly compatible with a wide range of materials ( filament; 2.85mm PLA, PETG, PBT, etc).

- Has tight tolerances advantage.

- Has a proximal feeder ( proximal feeder is more accurate than a remote feeder).

- Device has a self-developed FGF pellet extruder.

- Has a micro-motor technology that aids heat dissipation.

Price: $6,219.11

Pros:

- High printing capability with a speed of 200mm/s.

- Offer High flow extruding power, up to 20 times ( Max extrusion flow rate can reach 1600g/hour, 360mm³/s).

- High-quality cooling and heating.

- Offers a more stable operation.

- Effective heat dissipation.

Cons:

- Requires close monitoring due to its high flow rate.

- They are expensive to acquire.

3. Top high-value 3D printer

This 2020 model fully enclosed 3D printer is a precision-driven and low-noise 3D printer that creates fully realistic 3D objects. The device is very compatible with any kind of filament (PLA, PETG, PBT, etc). The 3.2-inch touch and color screen makes controlling the machine very easy, and it’s possible to carry out offline printing via SD card, and USB connection. The machine has a speed range of 30-250mm/s and is very compatible with materials such as TPU, La, Nylon, and ABS for its printing process. The printer is considered a high-value product due to its exclusive design —they include: tech-aided functionality, high-precision level, hardware configurations, and an efficient body design (including its industrial-grade tank chain design). This is arguably one of the best high-value 3D printers available in the market.

Features:

- Compatible with Windows, Linus and MAC operating systems.

- Has a 3.2-inch touch and color screen.

- 3-storeyed high-quality aluminum materials used for the heating platform.

- They can be used with a wide range of materials.

- Has a good tolerance rate.

- Super large molding size of 600 x 600 x 1000mm.

- This device has an inbuilt automatic leveling aid.

Price range: $2,053.29 – $2,250.72

Pros:

- Low noise operation.

- Easy to control with its touch screen technology.

- High level of precision.

- Well-distributed heating and revolving speed.

- Suitable for all kinds of filament ( TPU, La, Nylon, ABS).

- Aeronautical aluminum platform for heating, with excellent corrosion resistance.

- No warping nor out-of-shape printing.

- Low print failure rate.

Cons:

- The machine is weighty and will be difficult to move around.

- The machine requires close attention due to its high precision and speed level.

4. Top 3D printer for mini filament printing

ABS PLA 3d Printing Mini Filament Extruding Machine is an effective printer for home or laboratory use. The machine boasts a robotic control system (PLC control system), comes at an affordable price tag, and can produce different diameters of filament (from 1.5mm-3.0mm).

Features:

- Produces different raw materials: ABS PLA PA HIPS PET.

- Can effectively produce different diameters of filament from 1.5mm-3.0mm.

- The machine has a PLC full-automatic control system.

- This device has an inbuilt automatic leveling aid.

Price range: $500.08 (min order: 1 set) – $ 480.08 (min order: 5 set)

Pros:

- Has a low energy consumption rate (around 0.5kw per hour).

- Has a low maintenance cost.

- It’s an independently operated machine.

- It is environmentally-friendly.

- Has an economical price range.

Cons:

- Not suitable for industrial use.

- Not suitable for high-volume printing.

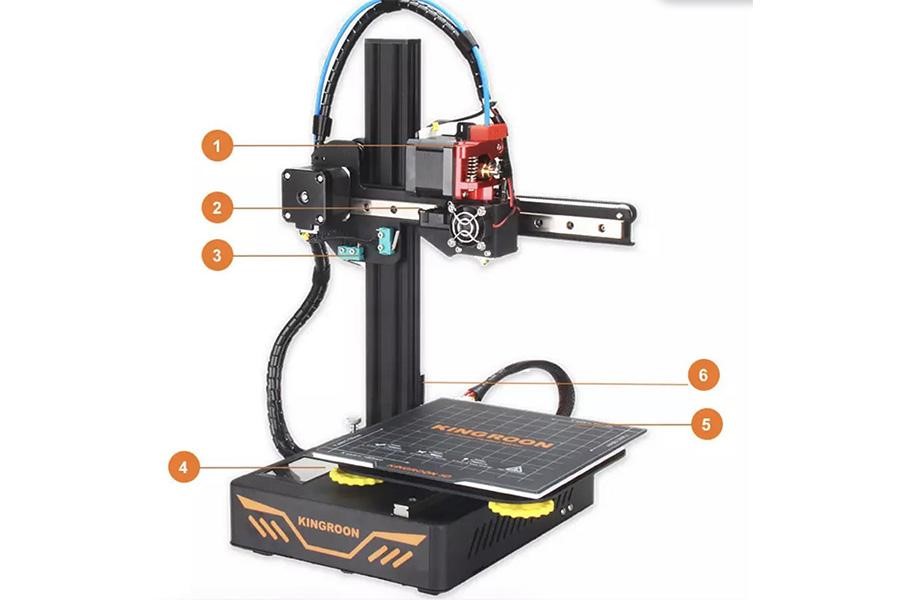

5. Top high-speed 3D printer

This standard FDM 3D metal printer has a unique compact design with a fast printing speed and a great design for portability, and it is compatible with different material types ( like ABS, PLA, TPU, PETG, and WOOD). The machine is fully enclosed in a metal frame (with a single extruder). Key highlights include a 180x180x180 mm inbuilt volume, a 0.4 mm diameter nozzle, auto leveling design, and high precision power with dual guide rails.

Features:

- 2.8 inch LCD touch screen (with 8 different language integration).

- Fast heating capability of up to 110 degrees in 8 minutes.

- Has the ability to print large objects up to 180x180x180 mm.

- Built with an auto leveling design.

- Has a high precision level with dual linear rails at the X & Y axis.

- Interface allows external connections (USB port, TF card, and USB Stick).

Price range: $129.01 – $144.01

Pros:

- Low noise, with an ultra-silent driver.

- Has high-quality cooling fans.

- Very compatible with filaments (ABS, PLA, TPU, PETG, and WOOD).

- Can print large-size objects.

- High printing speed and easily portable.

Cons:

- It is human-operated and requires lots of attention.

- Not environmentally friendly.

6. Top high precision 3D printer

The Artillery 3D Printer is a software-driven 3D device with smart technology integrations and a TFT controller that allows for high strength and high productivity. This is an exclusive high-end 3D printer featuring heat bed protection, automatic bed leveling, and ultra quiet design. The machine is designed for large-size printing, and for achieving smooth lining and finishes. This machine has a sensor design that detects a power failure and filament run-outs —it can trigger an alarm to alert the controller of situations of filament runouts. The machine is highly efficient and built with a power recovery system.

<alt=“A standard Artillery 3D printer”>

Features:

- High precision and refined design.

- Ultra-quiet printing ability.

- Touchscreen control.

- Tempered glass printing platform.

- Power interruption/filament runout detection.

- Synchronized dual Z-axis design and patented coupler.

Price range: $280.02 – $315.03

Pros:

- Large-size printing capacity.

- Offers convenient maintenance.

- Offers a large space for creative platforms.

- Easy to control using the high-definition color touch screen.

- Versatile functionality.

- Integrated Alarm system.

- Power recovery system.

- Offers ultra-quiet stepper driver and quiet printing.

Cons:

- Not environmentally-friendly due to the ray lights.

- Requires close monitoring and human control.

7. Top industrial 3D printer for ABS, HIPS, and PETG

The 3D Drucker is a fully functional industrial printer that is conveniently controlled by its 5.0-inch colorful touch LCD screen. This exclusive machine offers high performance and accuracy. Its printing head is compatible with nearly all kinds of filaments, which includes PLA, ABS, PLA composites (Carbon fiber, Wood, Copper, Brass, Magnetic ), PHA, PVA, Hips, Nylon, TPE & TPU (FleX), and PETG. It can retain heat due to its enclosed setting, and this is particularly good for ABS printing. The built-in UPS (Uninterruptible Power System) helps to retain machine memory for 24 hours after the power goes off.

Features:

- Adjustable Print speed range 0 – 200mm.

- Available 5.0-inch colorful touch LCD screen.

- 10mm thick aluminum heated bed, its max temperature can heat 110 degrees.

- Self-patent nozzle with a maximum temperature of 275 degree.

- UPS (Uninterruptible Power System) integration.

- Has a filament sensor that detects when a filament is present.

- Good automation and independent control.

Price range: $2500 – $3000

Pros:

- Easy to operate with the LCD touch screen.

- Offers convenient maintenance.

- Makes printing strong filaments like ABS and Nylon very easy.

- Easy to control using the high definition color touch screen.

- Can store memory up to 24 hours after power outage with the UPS system.

- Integrated Alarm system.

- Power recovery system.

- Offers ultra-quiet stepper driver and quiet printing.

- Requires little or zero supervision due to its auto power-off integration.

- High resolution and speed.

- Suitable for industrial use.

Cons:

- Limited data storage ability (can only retain data for 24 hours after power outage).

- The machine requires human assistance to kickstart its printing process.

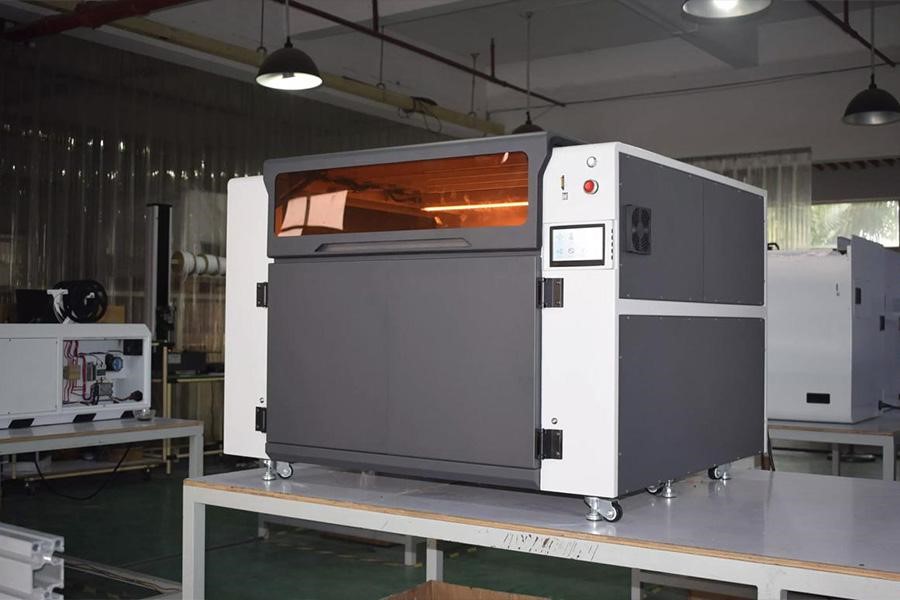

8. Top FDM printing machine

This highly effective FDM printing machine is speed-driven and can convert 2D files into 3D files using direct printing with zero pressure. The machine boasts a strong heat dissipation capacity and faster-curing speed. This machine is designed to meet various kinds of printing needs and can carry out large-size printing. Additionally, the high-precision linear guide rail silent transmission, and automatic leveling, help to ensure printing accuracy and printing sound quality.

Features:

- The device offers a strong heat dissipation capacity and faster-curing speed.

- FDM filament printing helps to prevent material waste and also minimizes noise.

- Has a high-precision linear guide drive that makes the parts more compact.

- The linear guide rail silent transmission for an increased machine functionality.

Price range: $3900.34 – $4,500.39

Pros:

- Can conveniently convert 2D file to 3D file via direct printing with zero pressure.

- Low noise printing.

- It has the potential to handle large size printing.

- The automatic leveling ensures printing accuracy and good sound quality.

- Heat insulation due to its enclosed body cavity.

Cons:

- They are not eco-friendly, due to the Ultraviolet light transmission.

- Excessive heat generation due to the enclosed body cavity.

- The machine operation key requires WiFi (internet connection ) to work effectively.

- The machine requires proper training to operate it.

3D printers target market

3D printers have huge market potential. The technology, which is otherwise known as additive manufacturing, is changing the way businesses and organizations operate and industries like medical, automotive, manufacturing, energy, and aerospace are utilizing this technology for innovative purposes.

The main market for 3D printing is businesses looking to create new prototypes for their products and companies looking to create parts or products on-demand. Similarly, 3D printers market target would include companies that produce artificial body parts, or businesses that manufacture objects for home use or market sales. With this in mind, any of the aforementioned high precision, high performance 3d printers would make a great inventory item for any business aiming to capitalize on this growing demand.