Fashion designers have been using cloth-cutting machines to create quality fabrics for many years. What makes cloth-cutting machines a better choice for many fashion designers are the speed and the ability of the machines to cut fabrics in different shapes and sizes. Buying cloth-cutting machines is a bit tricky because there are so many of these machines available in the market. Before choosing to invest your money in any of them, it is important to know their capabilities as well as their pros and cons.

This article will focus on the tips for selecting the right cloth-cutting machines and the different types of these machines. Additionally, it will look at the market share and size of the cloth-cutting machine market.

Table of Contents

Overview of cloth-cutting machine

Types of cloth-cutting machines

Tips for selecting the right cloth-cutting machines

Conclusion

Overview of cloth-cutting machine

The demand for cloth-cutting machinery is on a steady to rapid rise globally. This is due to the increased need for ensuring accuracy in garment cutting and minimizing the wastage of materials. Also, the textile industry has been greatly shaped by the development and advancements in the technology of fabric-cutting equipment. This has resulted in a prolific expansion of the overall cloth-cutting machinery market.

Based on a report by Future Market Research, the global cloth-cutting machinery market was estimated to have surpassed USD 5 billion by 2022. It was further projected to expand at a compound annual growth rate (CAGR) of 9% to reach USD 7 billion by 2032. The growth is ascribed to the worldwide surge in textile industries and the subsequent rise of the need for textile products.

The market segments include machine type, cutting type, product type, fabric type, end-use, and regions. Fabric cutting by use of laser technology has increased in demand in countries like China and India. The North American region is expected to lead the cloth-cutting machinery market. As for the Asia Pacific, rapid modernization is anticipated to drive the use of cloth-cutting machines. Also, some key manufacturers like Tukatech Inc and FK Group Srl are developing their machines to gain a competitive advantage in the global market.

Types of cloth-cutting machines

1. Manual cloth-cutting machine

Manual cloth-cutting machines are controlled and operated by hands. Traditionally, the cutting process was done with knives, drills, or scissors. Nonetheless, there has been advancement in manual cutting to enhance efficiency. For instance, in the use of die-cutting machines, the fabric is put between the mat and the die and cut as it is fed through the machine.

Pros

– They are easily portable.

– They are simple in nature and thus are easy to use.

– They have enhanced safety for the user.

Cons

– They are limited to small-scale tasks as fabric handling is difficult.

– They are slow or cannot cut heavy garments.

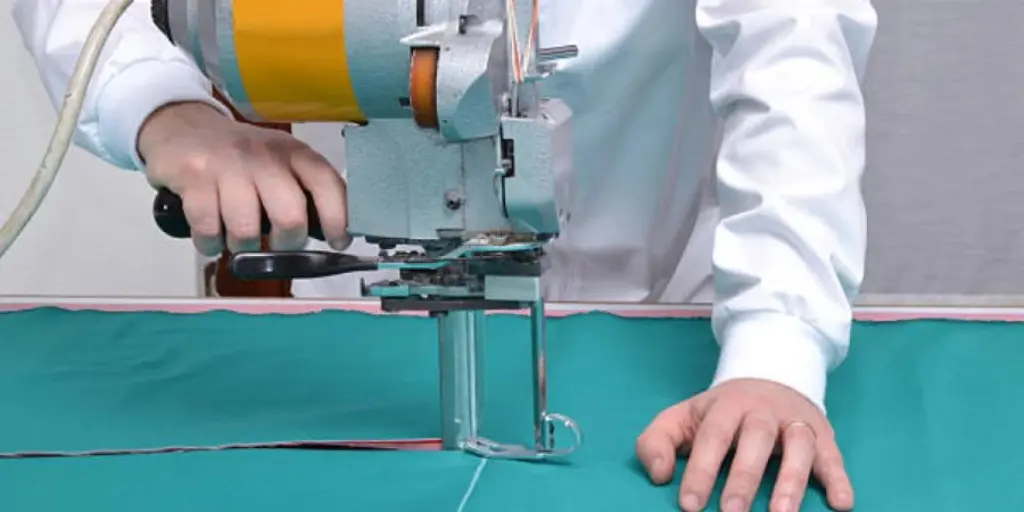

2. Semi-automatic cloth-cutting machine

Semi-automatic cloth-cutting machines are mechanized and operate both in automatic mode and manual mode depending on the processes. These specific processes often use magnetic or electronic tracers to follow the defined patterns. The fabric cutters produce almost similar results of accuracy while operating in both automatic and manual modes.

Pros

– They have improved productivity compared to manual machines.

– They have higher speed and accuracy levels due to additional features.

– They can be used without a power supply.

Cons

– The heavier the fabric, the more difficult it becomes to cut using these machines.

– In the case of fabric blocks, wastage is higher.

3. Fully automatic cloth-cutting machine

Fully automatic cloth-cutting machines have various types of cutting techniques. Firstly, the computerized cutting method is used in high-volume fabric production lines. The machines cut layers of fabric based on the command prompt by the computer system. The auto spreader positions the fabrics on the cutting table prior to cutting. Secondly, instead of using blades, laser rays controlled by a computer are used to cut the cloth.

Pros

– There is minimum or no wastage of fabric material.

– High precision and speed minimize the cost of cutting.

– They are flexible and produce quality cuts.

Cons

– They are relatively expensive to acquire.

– Some of these machines are huge and thus use a lot of space.

4. Vibrating knife cloth-cutting machine

Vibrating knife cloth-cutting machines are used to cut flexible fabric materials. They use an up-and-down high-frequency motion of the blade for cutting. These machines are quite fast, achieve high accuracy, and have no limitations in cutting patterns. On top of that, they can load and unload materials.

Pros

– The finished products are clean, neat, and have smooth edges.

– They produce accurate fabric pieces.

– They have a wider range of applicability that goes from light to heavier fabrics.

Cons

– This technique has a high workload.

– There are difficulties when cutting cloth directly from lay.

Tips for selecting the right cloth-cutting machines

1. Size

The available working space determines the size of the cloth-cutting machine to be acquired. A basic cloth-cutting machine is about 10 inches. Not every room or available space can accommodate larger fabric cutters. A manual cloth cutter would be ideal for a relatively small working space. The large computerized fabric-cutting machines require a factory setting to fit well and leave room for operators and fabric materials. The size of the blade for a cutting machine should be considered too. Some industrial automatic fabric-cutting machines have a machine blade size of up to 1,000 mm.

2. Precision

When precision is maximized in fabric cutting, there is the prevention of recurrent cutting operations. Generally, an ideal fabric cutter can accurately cut to shape 1-6 layers of fabric. The adoption of various cloth-cutting machines in the textile and fashion industry has increased cutting perfection while reducing modification times for close sizes and styles. Higher precision means a reduction in material wastage in the cutting process. This capability greatly improves garment quality due to the appealing appearance of the finished products.

3. Cost

Like in other vocations and industries, the cost is an equally important consideration in the selection of the right fabric-cutting equipment. The quality of a cloth cutter determines its cost. Quality is ascribed to the capabilities and efficiency of the machine in question. For instance, entry-level models of laser fabric cutters cost around USD 5,000 and upwards for high-end industrial ones. Some businesses would prefer electric machines but they may not afford them. Therefore, based on buyers’ production needs, they should stick to the budget while purchasing fabric-cutting equipment. The budget should include the initial purchase price, the accessories cost, and the potential maintenance cost.

4. Ease of use

Ease of use is tied to the fabric cutting objectives of a buyer and the complexity of the cloth-cutting machines. Potential designers will need simple cutting machines as they are easy to learn and use. They will instead advance their choices of cutting machines as they improve their skill set in various cutting techniques. Buyers experienced in textile production and fashion design might have stumbled on basic cloth-cutting equipment. However, they will need to use more advanced cutting equipment for their garments to handle the high levels of workflow.

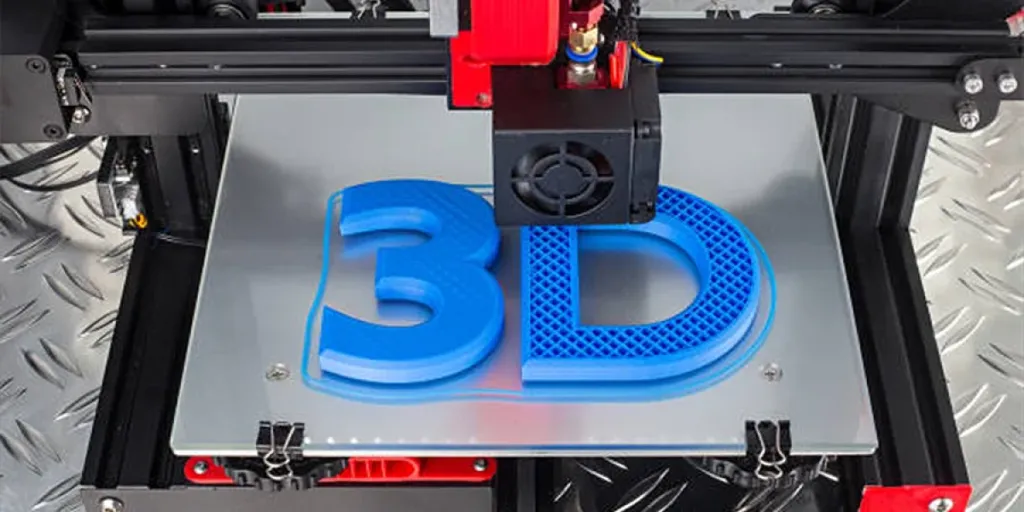

5. Software

The ideal fabric-cutting equipment that is likely to satisfy buyers’ needs uses advanced software. This makes the machine’s operations more intuitive. Notably, the right software guides the buyers in most of the cloth-cutting process. It also enables them to achieve the desired designs within a minimum time. For instance, some professional laser cutting machines use computer-aided design (CAD) technology.

6. Type

Different brands may produce different types of fabric-cutting machines. These machines include the Cricut Maker 3, Silhouette Cameo 4, and Sizzix Big Shot Plus. Most of these machines come in manual or automatic modes. Based on their budgets, buyers can select the most appropriate machine suited to their production lines. Nonetheless, beginners should go for manual options because they are easier to use. Later, they will use more complex machines based on their production levels.

7. Speed

The speed of fabric-cutting machines is vital in the event of bulk cutting in a production line. On average, CNC fabric cutters operate at a speed of 80 m/min with a cutting height of up to 8 cm. They also have a width availability range of 1.6 to 2.6 m. High-speed & high-ply cutting generally improves productivity. Buyers should be aware that mass production requires automation to handle large volumes of fabric materials in less space and time.

8. Applicable material

Cloth-cutting machines can cut various types of garments. Generally, the common fabrics include cotton, felt, denim, lace, fleece, and polyester silk. Buyers should note that not all cutting machines can be used on all these cloth materials. As a result, they should select machines based on the fabrics they deal in. For instance, buyers who intend to deal in Alcantara, acrylic, and softshell textiles should opt to use laser fabric-cutting machines.

Conclusion

It is quite challenging for buyers to arrive at the right choice of cloth-cutting equipment. Buyers should however take their needs into account when seeking to invest in fabric cutters. Regardless of the machine type (manual or automatic), fabric cutters have many benefits, including quicker results with optimum precision.Consider the differentiating factors mentioned above and find quality cloth-cutting machines on Alibaba.com.