There are a wide range of feed processing machines available on the market today. These can vary from small farm or home pelleting machines for pets, poultry, fish and small animals, to large industrial machines that handle the full process with a high production output. If you are exploring the market for feed pelleting machines, this article will help you to find a machine that best matches your needs.

Table of Contents

The growth of the feed processing market

What to consider when selecting a pelleting machine

Different types of feed pelleting machines

Target market for feed pelleting machines

Final words

The growth of the feed processing market

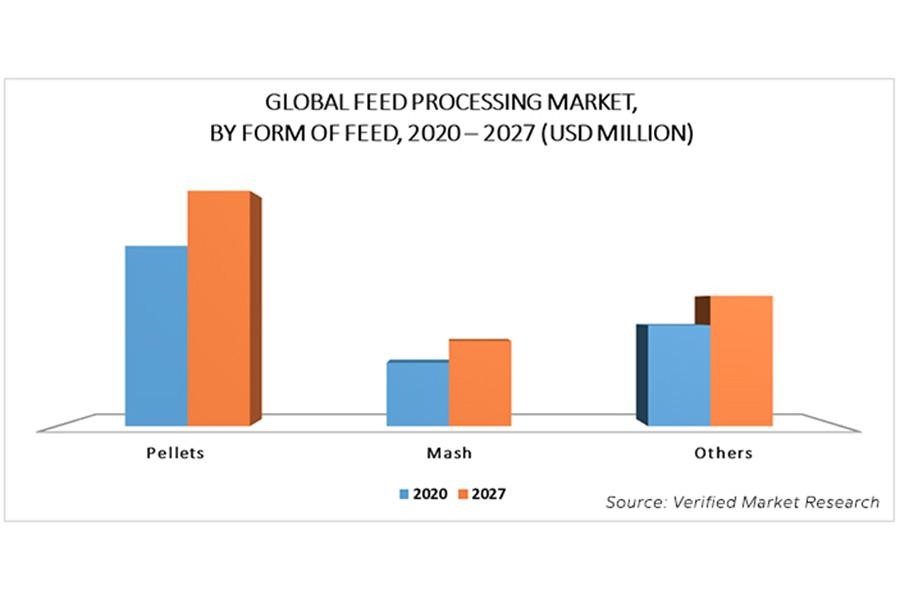

In 2021, the global feed processing market was valued at $20.86 billion and is projected to grow at a compound annual growth rate (CAGR) of 4.4% to around $26.62 billion by 2027. Increased feed costs are partially driving this growth together with a better awareness of the more balanced and healthier feed combinations that pelleting can provide. Feed pellets allow for measured mixed nutrients, easy transportation and storage and less wastage, and as a result the market is expected to grow faster than mash feed or other types.

To meet this growth, the global demand for feed processing machines is also projected to grow from a 2020 value of $4.08 billion to $5.6 billion by 2027, at a comparable CAGR of 4.5%. Of the different feed processing machines available, including grinding, mixing and pelleting machines, pelleting machines currently hold around 40% of the market and are expected to continue to grow steadily.

What to consider when selecting a pelleting machine

Producing animal feed pellets is a process that covers cleaning, grinding, mixing, pelleting, cooling, and packing. Each step of the process typically requires a separate machine. For low volume processing these can be individual machines arranged in sequence, assembled so that each machine feeds its output into the next machine, usually via a conveyor belt into a hopper. In large scale production, a single machine may cover several parts of the process.

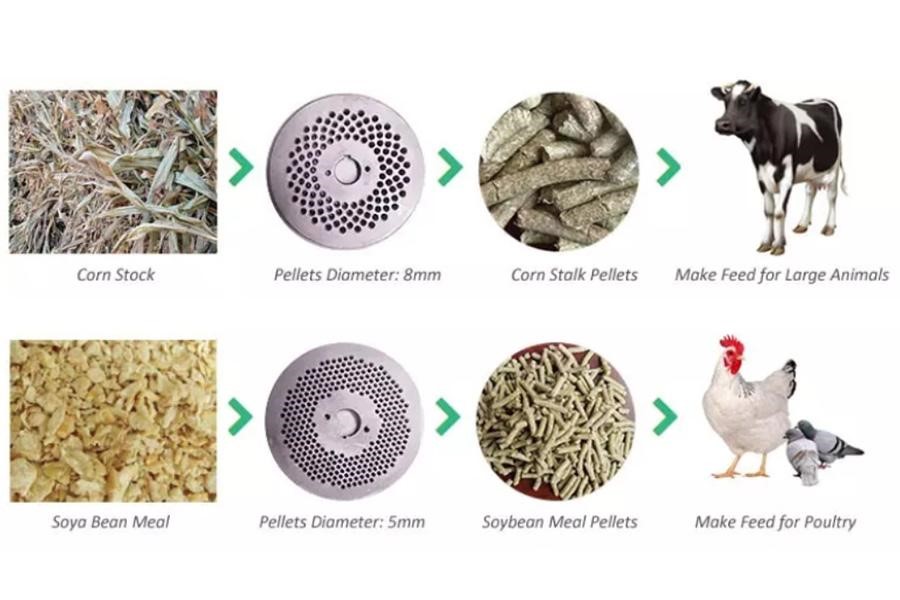

Because pelleting machines fit within the wider feed production process, the feed mix arrives at the pelleting machine with a predetermined nutritional balance and moisture level. The pelleting machine then takes the pre-ground and pre-mixed food contents, heats them, and then presses the mix through small sized openings, which are then cut at a determined length into granulated pellets. The pellets are then cooled and dried, which extends their storage life and readies them for packing and shipping.

The width of a pellet is determined by the gap sizes in a die, which is calibrated to make specific animal feeds. Different animal pellet feeds include poultry, bird and fish feeds for industry, small and large pet feeds, and other large animal feeds for cattle, sheep, goats and pigs. Most machines can be adapted to process different kinds of feed mixes and different sizes of pellet for the chosen animal feed.

The process of pressing the mix through the measured openings in the die is called extrusion, and feed pelleting machines are sometimes called feed extrusion machines. In the following section we look at the different feed pelleting, or extrusion, machines available, from the smaller machines that tackle the pelletizing only, to the larger industrial machines that handle the entire process as a production line.

Different types of feed pelleting machines

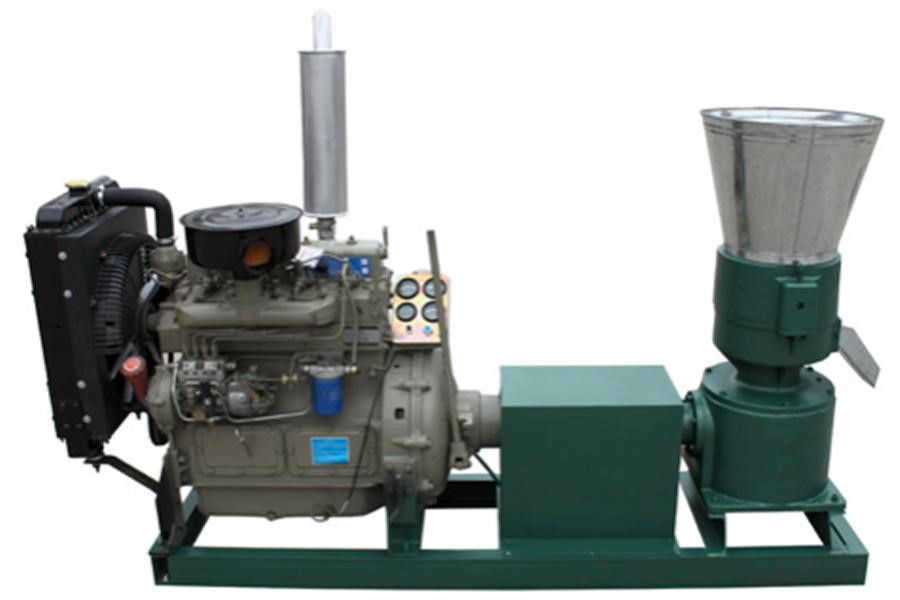

In general, pellet machines are classified into either flat die or ring die pellet machines. Both work by compressing the feed mix through holes in the die and are then cut to the required length. Flat die pellet machines are smaller, simpler to maintain, but have a lower production capacity, so tend to be more suitable for home and small farm use. Ring die pellet machines are larger, more complex, and more expensive and preferred for high capacity production.

Flat die pelleting machines

Flat die machines use a flat die with slots running through it. The premix feed is introduced to the top of the die in powder form, the die rotates, and a roller presses the mix through the openings in the die. As the feed is pressed through, the pellets are cut to the correct length.

Advantages of flat die machines

- They have a simple structure, and are small, light, and portable

- They cost less than a ring die pelleting machine

- They are easy to operate and maintain

- The pelletizing process can be monitored easily, and faults can be addressed early

- They are popular with farmers, small businesses, and home users

Disadvantages

- They have a low capacity from 100kg per hour to 1,000kg per hour

- Flat dies wear and need replacing regularly (although they can be flipped over, which extends their life)

- The production capacity is on the lower end of the scale

Ring die pelleting machines

In ring die machines, the die is tube-like, with radial slots around it. The premix powder is fed to the middle of the die and then spread evenly around the outer edges. Rollers then compress the mix through the die holes, and cutters chop the pellets to the designated length.

Advantages of ring die machines

- They have high capacity production from 800kg per hour to 20t per hour

- They have relatively lower power consumption per unit

- There’s less wear between roller and die so less frequent replacement

- Operation and maintenance is easy

- They process consistent and uniform pellets

Disadvantages

- There’s less pressure between roller and ring die so it takes more effort to adjust the clearance

- Much higher cost per unit than flat die pelleting machines

- They take up more space as they are large and heavy

Building a complete production line

Because the pelleting machine is only a part of the broader feed process, there are solutions available that provide the entire process. Various machines can be combined to form a full production line for high capacity throughput, from around 0.5 tons up to 10 tons or more.

As these are intended for a large-scale production process, they are designed and calibrated for one food type, with typical feeds being poultry, fish feed, dog and cat food, or larger livestock such as cattle. When building a large-scale production line, it is typically advised to purchase and arrange machines from a single supplier so that the machines will work well together.

Target markets for feed pelleting machines

Globally, poultry meat production is growing, with 66% of that increase in the Asia Pacific region. The global poultry feed market is projected to grow at a CAGR of 4.2% through 2027, with a continuing high demand across the Asia Pacific region, particularly in China and India. This will lead to an increased use of high quality feed for the growing poultry population, and more focus on feed pelleting. The fish feed market is projected to grow at 9.9% CAGR through to 2027. The US is currently leading the demand for fish feed followed by Europe and the Asia Pacific region, but this region is expected to grow faster due to a growing population and increasing aquaculture industry.

Compared to poultry and fish feed, the ruminant feed industry (dairy and beef cattle, sheep, and goats) is projecting a slower growth, with a CAGR of 3.2%. The global pet feed market is projected to grow at a CAGR of 4.4%, with the US currently holding almost 50% of the market, and 40% of that being for dog food. Europe is looking at a potential growth of 4.5% CAGR followed by a slower Asia Pacific at 3% CAGR.

Final words

The market opportunity for feed pellet production is largely driven by the increased interest in higher nutritional meals to promote better animal health, and the easier storage and transportation that pelleted feed provides. The demand for pelleting machines will therefore also grow, and for those looking to get into the feed machine market there will be plenty of opportunity. However, as pelleting comes later in the feed processing cycle, it would also be important to consider the wider process as well. For more information on pelleting and other feed processing machines, and to explore the models available on the market today, check out Alibaba.com.