After being used for some time, some metal parts or tools will begin to rust. This is because the air and water in the surrounding environment causes oxidation and other problems.

Rust on these metal surfaces will reduce the service life of the metal tools or parts and make using these metal utensils difficult. In order to ensure the good cleanliness and roughness of these metal surfaces, their structure must be de-rusted.

There is a saying in the anti-corrosion industry which shows the importance of rust removal; it states that there are “seven points for rust removal and three points for painting.” But how can one remove rust from a metal surface? And how many easy ways are there to do it?

You can use power tools or chemicals to clean rusted metal tools, or you can use a homemade rust remover to clean rust from metal parts. The below listed options constitute my summary of the 18 best ways to instantly remove rust from metal.

Table of Contents

Laser cleaners for rust removal

Power tools for rust removal

Chemical rust remover

Rust converter

Homemade rust remover

FAQs

Laser cleaners for rust removal

Laser rust removal

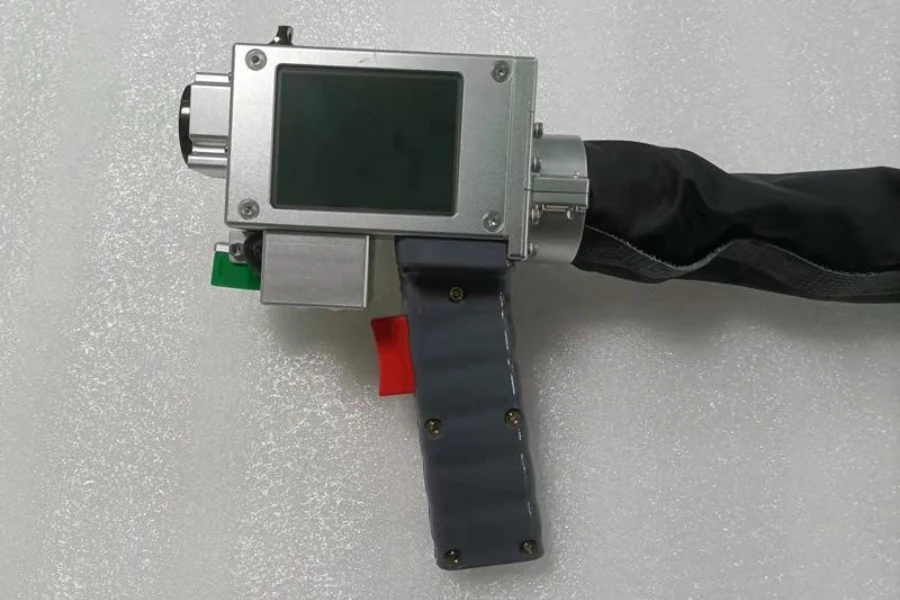

Laser rust removal machines are a type of portable rust cleaning tool that uses a laser beam to remove rust or coating from the metal surface. These machines usually work with a high-speed handheld laser rust removal gun.

Pros

Laser rust removers are highly efficient, fast, low cost, and do not damage the substrate. No water or solvent is required and the waste is easy to collect and does not pollute the environment. They are also safe and reliable, and do not damage the health of their operators.

Laser rust removers have a wide range of applications for removing rust, scale, dirt, and coatings of various thicknesses and compositions. The cleaning process is easy to automate thanks to its long-distance remote control functionality. It can be used for both small-scale and large-scale laser rust removal work.

Cons

The disadvantage of using laser rust removal is that it requires the laser itself, as well as the corresponding supporting equipment. All of this equipment is expensive, making it a significant one-time investment. However, once this is paid there are near no maintenance costs.

Power tools for rust removal

Ultrasonic rust removal

With ultrasonic rust removal, the high-frequency vibration signal announced by the ultrasonic generator is converted into high-frequency mechanical vibrations by the transducer and then propagated into the medium. The small air bubbles in the liquid begin to vibrate under the effect of the sound field. Then, once the sound pressure reaches a certain value, these air bubbles will grow rapidly and then close suddenly, causing a shock wave. This damages the insoluble dirt, loosening it and propelling it into the cleaning solution. During this process, the solid particles are separated, thereby removing rust from the surface of the metal parts.

Sandblaster rust removal

Sandblaster rust removal uses a sandblasting gun to blast small sand particles through compressed air onto the rusted surface of the metal part. This method not only achieves rapid rust removal but also prepares the surface for painting, spraying, electroplating, and other processes.

Sandblasting of the metal part to be treated changes the appearance or shape of the metal surface, as well as improving the mechanical properties and the fatigue resistance of the metal part, increasing its adhesion to the paint, and prolonging the durability of the paint film. It is also conducive to the leveling and decoration of the paint.

Quartz sand is usually used for this sandblasting method. It is made from high-quality natural quartz sand ore, which is refined through mechanical crushing, washing, screening, drying, secondary screening, and other processes. Quartz sand features high mechanical strength, no impurities, compression and wear resistance, good chemical stability, uniform particles, high efficiency, and recyclability.

High-pressure water gun for rust removal

Under normal circumstances, it is best to use a high-pressure water gun to rinse and remove rust from metal surfaces. Usually, the power-driven pump completes a suction and discharge process for water, converting this ordinary water into high-pressure and low-flow water. Then, it sends the water to the high-pressure pipeline, ensuring it reaches the high-pressure nozzle with a certain amount of energy. The high-pressure water gun cleaning components then suck sand into the sandblasting head and mix it with the high-speed and high-pressure water column. The high-speed and high-pressure water column mixes the sand while shooting it onto the metal surface. In this way, the high-pressure water gun combines the sand’s friction and the force of the high-pressure water flow to easily remove paint or rust.

Angle grinders for rust removal

Abrasive rust removal requires a lot of manual labor. However, it is a very effective technique.

An angle grinder is one such tool that can be used for his method. It is also an easily accessible tool since grinders use steel wool, which can be bought at any local store. If the metal part is large and there is a lot of rust, however, a power sander may be more helpful. Start with coarser grains and work your way up to finer grains to minimize the damage to the metal part. Other hand tools, like screwdrivers, can help you scrape away rust, but be sure to use fine-grit sandpaper to remove any scratches once you’re done.

Chemical rust remover

If you do not wish to use tools, you can opt for chemicals to dissolve rust. However, these chemicals are usually made with oxalic or phosphoric acid, which can damage your skin. For this reason, you need to be very careful when using them and always wear gloves when handling chemical products. Additionally, be sure to follow the product’s specific usage instructions, as applications may vary from product to product.

Most chemical removers take a fair amount of time to work and often require a brush afterwards. These products can also be a bit expensive, which is why chemical rust remover is most often used for small-scale rust removal.

Rust converter

Instead of removing rust, converters work by reacting with existing rust to stop further oxidation. Rust converters look like spray paint and are used as a primer for new paint coats on metal. For this reason, rust converters are a good choice if you plan to paint your metal tools or parts.

NOTE: When using chemical rust removers or rust converters, make sure you are outside in a well-ventilated area.

Homemade rust remover

Citric acid rust remover

To make this homemade rust remover, go to your local supermarket and buy a small box of citric acid powder. Pour some acid into a plastic container and add some hot water — creating just enough liquid to cover the metal tool or part. Dip the part or tool into the mixture and watch the bubbles rise. Leave the tool or part in the mixture overnight, rinsing it with water in the morning to finally remove rust from the metal.

Diesel rust remover

For this homemade rust remover, buy a liter of diesel (not a fuel additive). Pour the diesel into a container and put the rusted tool or part in it. Let the part or tool sit in the diesel for about 24 hours. After this period has passed, remove the part or tool and scrub with a brass brush. Then wipe the tool or part with a clean rag. Don’t forget to save the diesel for future use, as you may need to remove rust again in the future. Put the diesel in a tightly closed jar for safekeeping.

Vinegar rust remover

White vinegar reacts with rust, dissolving it from the metal part or tool. The reason vinegar is so effective as a rust remover is because the acetic acid in vinegar reacts and forms iron III acetate, which is a water-soluble substance. This means that vinegar can remove rust from water but not from tools or parts, so you’ll need to brush or wipe off the rust.

To use a vinegar rust remover, just soak the metal tool or part in white vinegar for a few hours and then brush off the rusty paste. If the rust seems springy and doesn’t come off easily, dip some aluminum foil in the vinegar and then brush the rust away using that. You can also remove the rust more easily by using a metal brush or steel wool.

How long do I soak metal in vinegar to remove rust?

If you’re using regular vinegar, the process will still work but it will take longer to achieve the desired results — possibly around 24 hours. The good news is that after those 24 hours, you probably won’t need to do a lot of scrubbing to remove rust.

Lime & salt rust remover

When using a lime and salt rust remover, coat the rusted area generously with salt and sprinkle some lime over the coating. Leave it for as much time as you can, but a general rule is to let the mixture set for a minimum of 2 hours before wiping it off. I recommend brushing off the mixture with a lime rind. This way, you will effectively remove the rust without causing further damage to the metal. Feel free to use lemon instead of lime.

Baking soda rust remover

Baking soda is an easy-to-use and effective rust remover for metal parts and tools. First, clean and dry the tool or part. Then, add some baking soda to water and mix until achieving a thick paste that you can spread on the rusted metal surface. Apply the paste and then let it set before scrubbing it off carefully with a brush. For smaller surfaces, you can use a toothbrush to remove the paste. Finally, rinse the part or tool with clean water and dry.

Potatoes and dish soap for rust removal

Another homemade rust remover consists in using potatoes and dish soap. First, cut the potato in half and wipe the cut end of one half with some dish soap. Then, rub this half of the potato against the metal and let it sit for a few hours. Generally, solvents react well with potatoes and rust to remove rust easily, so if you don’t have dish soap you can also use baking soda and water. Mix the soda and water with the potato and follow the same procedure as you would with dish soap to remove the rust from the metal part or tool.

Oxalic acid rust remover

When using an oxalic acid rust remover, you need to be careful and take precautions. First, make sure you have a pair of gloves, some protective clothing, and goggles at the ready. In addition, do not smoke when near the rust remover or inhale the fumes from the acid.

The first step here is to wash the rusted part or tool with a cleaning solution, then rinse well and let it dry completely. Next, mix five teaspoons of oxalic acid with about 300 milliliters of warm water. Once done, soak the part or tool in the acid mixture for about 20 minutes and then scrub the rusted parts with a brass brush. Finally, rinse the tool or part with clean water and allow it to dry.

Lemon juice rust remover

Lemon juice is very acidic and removes rust quickly. All you need to do is rub your rusty tools or parts with some salt, add lemon juice on top, and then let it sit for a few minutes. Don’t let the lemon juice stay on the tool or part for too long or it will damage it further. This is a great natural rust inhibitor that leaves your tools and parts smelling like citrus fruit. If you want to make the lemon juice even more effective, simply add some vinegar to the mix.

Coca-Cola rust remover

Have you ever wondered if Coca-Cola can remove rust? The answer is yes, it can because Coca-Cola contains phosphoric acid. This is a common ingredient in many rust removal products since it effectively removes rust.

For this homemade rust remover, all you need to do is soak the rusted tool or part in Coke for a few minutes and watch to see if the rust loosens and falls off the metal. Coca-Cola can be used to remove rust from a variety of metal objects, including nuts, bolts, battery terminals, and even cutlery. The only downside to this method is that it is a sticky process, meaning you must clean the metal part or tool well once finished.

Soda and Ketchup rust remover

For this easy and affordable rust remover, all you have to do is mix water with washing soda. Then, spray the rusted metal with the soda water and brush the rusty surface with ketchup. Next, let the ketchup and soda sit on the rusty area for 120 minutes and then rinse with water to reveal the clean metal surface underneath.

Toothpaste rust remover

Everyone has toothpaste at home, making toothpaste rust remover an inexpensive way to remove rust from tools or parts. To use this method, put the toothpaste on a piece of fabric and rub the part or tool, focusing on the rusted patch. Next, leave the paste on the metal for about 10 minutes and then rinse. For the best results, use a white toothpaste, not a gel variety.

FAQs

What is rust?

Rust refers to the oxides produced on the surface of metals (including alloys). Rust is formed by the redox reactions between metal and oxygen, with different conditions producing different forms of rust. Rust is mainly composed of ferric oxide hydrate Fe2O3·nH2O and ferric hydroxide (FeO(OH), Fe(OH)3).

Aluminum can become oxidized, but it is usually not called rust because aluminum oxidation is very slow. Aluminum undergoes a process known as passivation, where the oxygen forms a dense aluminum oxide film on the surface. Iron, on the other hand can become completely oxidized to rust after enough time in the presence of sufficient oxygen and water.

Why does metal rust?

Rusting is the chemical reaction that is the oxidation of metals. The most common rust phenomenon is when iron products have been exposed to air for a long period of time, which can cause an oxidation reaction between the iron and oxygen. Another common rust phenomenon is when iron becomes eroded by the oxygen in water to then become oxides.

How to remove rust?

You can use various tools to blast or soak rust off a metal surface. Of course, the best way remains laser rust removal, as this method is not only fast and clean, but also prevents further damaging the metal surface. After removing rust, the metal surface must always be treated, coated with a layer of lead, and then painted or plated with other metals that do not easily rust.

How to prevent metal from rusting?

Covering a metal surface with a protective layer is a common and important method used to prevent the rusting of iron products. Keeping metal surfaces clean and dry is also a great way to prevent rust. Of course, there are also ways to use metal alloys to change a metal’s internal structure and increase its rust resistance.

Source from stylecnc.com

Disclaimer: The information set forth above is provided by stylecnc independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.