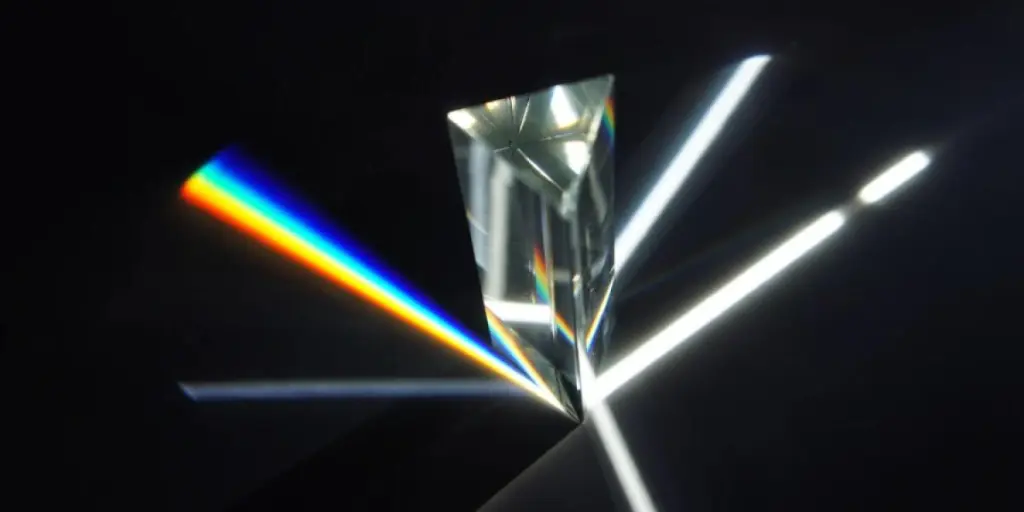

Modern technologies such as optical computing, integrated photonics, and digital holography all require flexible manipulation of light signals in three-dimensional space. In this process, shaping and guiding the flow of light according to the desired application is crucial.

Because the flow of light within a medium is controlled by its refractive index, specific manipulation of the refractive index is required to control the optical paths within the medium. To achieve this, scientists have developed so-called “aperiodic photonic volume elements” (APVEs), which are microscale voxels with specific refractive indices placed at predetermined positions to guide the flow of light in a controlled manner. However, carving these elements requires high precision, and most light shaping materials are limited to 2D configurations or ultimately result in reduced output beam profiles.

Recently, a study published in the photonics journal “APNexus” presented a simple method for producing high-precision APVEs, and demonstrated their use in a range of applications. The research was led by Alexander Jesacher from the Medical University of Innsbruck in Austria, and it overcomes the limitations in light shaping mentioned earlier.

The method uses a technique called “direct laser writing” (DLW), which is a high-speed laser technology that arranges voxels with specific refractive indices in three dimensions inside borosilicate glass to precisely guide light for various applications.

According to reports, the researchers designed an algorithm that stimulates the light passing through the medium to determine the optimal position of the voxels to achieve the necessary accuracy. Based on this, they were able to generate 154,000 to 308,000 voxels in 20 minutes, with each voxel having a volume of approximately 1.75 μm × 7.5 μm × 10 μm. In addition, they used dynamic wavefront control to compensate for any spherical aberration (beam profile distortion) of the laser focused on the substrate during the process. This ensured the consistency of the profile of each voxel at every depth within the medium.

The team developed three types of APVEs to demonstrate the applicability of the method: an intensity shaper for controlling the intensity distribution of the input beam, an RGB multiplexer for controlling the transmission of red, green, and blue spectra in the input beam, and a Hermite-Gaussian (HG) mode sorter for enhancing data transmission speed.

The team used the intensity shaper to convert a Gaussian beam into a microscale smiling arc-shaped light distribution, then used the multiplexer to represent different parts of the smiling arc-shaped distribution in different colors, and finally used the HG mode sorter to convert multiple Gaussian modes transmitted by optical fibers into HG modes. In all cases, the device was able to transmit the input signal without significant loss and achieve a record-breaking diffraction efficiency of up to 80%, setting a new benchmark for APVEs.

This new method opens the door to an ideal low-cost platform for rapid prototyping of highly integrated 3D light shaping devices. In addition to its simplicity, low cost, and high precision, this method may also be extended to other substrates, including nonlinear materials. Its flexibility makes it suitable for designing a wide range of 3D devices for use in fields such as information transmission, optical computing, multimode fiber imaging, nonlinear photonics, and quantum optics.

Source from ofweek.com