Printing involves producing text and images on a substrate using templates or master forms. The first printing technique, woodblock printing, revolutionized printing processes as technology continued advancing. These printing methods are no longer popular because of technological changes and the effectiveness of the techniques.

Today, there are various printing techniques, each used on different substrates. This article will examine the most popular printing process businesses adopt. We will also discuss other options that commercial printing enterprises are using. Keep reading to learn more.

Table of Contents

Global printing market size

Most common printing process display

4 other popular printing process display

Conclusion

Overview of the global printing market

The global printing market is estimated to be worth US $344.19 billion in 2023. It is projected to grow at a compound annual growth rate (CAGR) of 3.1% to US $388.33 billion by 2027. The upward growth emerges from businesses adopting digital inkjet printers that produce high-quality prints on substrates. Most of the revenue from printing comes from printing newspapers, plates, textiles, billboards, and packaging.

Based on the type of technology, the report reveals that flexography, rotogravure, digital and offset printing are major contributors to the market’s major growth. Therefore, businesses entering the printing sector can adopt these methods to meet the needs of their customers.

Most common printing process display

Offset printing

Offset printing is a common printing technique that produces high-quality prints on materials. It involves transferring a printed image or offset from a plate to a rubber blanket on surfaces through direct contact.

The printing process begins with the prepress stage, where digital files are broken down by color separation and laser-edged or coated to aluminum plates.

Each plate is loaded onto a roller known as a plate cylinder. The cylinder rotates with each revolution dampening the non-image area of the plate with water from the dampening system.

An oil-based ink then passes through a series of rollers onto the plate’s image area. The image is then offset onto another cylinder with a rubber blanket. Adding this process results in a clear and sharper image; hence, the name offset printing.

Paper is loaded onto the start of the press and separated by air jets to ensure that only one piece travels at a time. Then, the paper goes through the blanket and impression cylinders. Here, it receives the printed image before passing it on to the next unit to receive the next color.

After the page has traveled through each unit, it is piled at the end of the press with a thin layer of powder. This process helps separate each page so the printed image can dry without marking the pages above and below.

Although offset printing has a high cost in the initial setup, it is suitable for printing huge volumes. The price per unit eventually drops as the number of materials to print goes up.

4 other popular printing process displays

1. Screen printing

Screen printing is also a significant printing process that most businesses use today. The process begins with a setup where one mixes ink according to the requirements of an artwork.

The screen printing machine pushes the ink along using a squeegee and squelches it back through the screen into the T-shirt. Ultimately, it results in a lovely thick block color with beautiful detail.

However, it requires putting one color at a time. It, therefore, changes how one prepares artwork for printing. One must think about reducing the number of colors. Setting up the screen is a time-consuming and costly process.

For screen printing to be economical, businesses should get the least number of colors to make the setup easy. After setting up one color, it reduces the printing cost per T-shirt.

Who does screen printing suit? Screen printing works well for clients or businesses with a massive stock volume with one or two colors in their design. If the T-shirt design has multiple colors, digital printing is the right option.

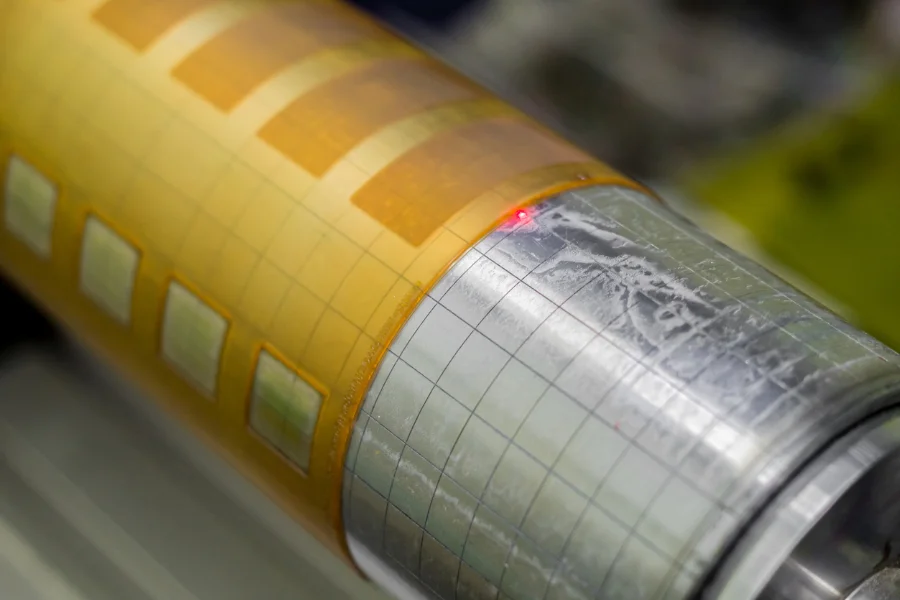

2. Flexography

Flexographic printing is a popular printing process in the world today. It mimics a high-output version of rubber stamping, only that one uses a large flexible plate that transfers designs to materials.

A flexographic printing machine has four components that make the printing process possible. They include a fountain roller, anilox roller, plate cylinder, and impression cylinder. The ink to apply on a material sits in an inkwell. The fountain roller picks it up and transfers it to the anilox roller.

An anilox roller with tiny cells on it picks up the ink from the fountain roller. More cells per ink result in more ink coverage on a substrate. It then transfers the ink to the plate cylinder. The plate cylinder is where the image design is situated.

The material to apply the print design goes between the plate cylinder and the impression cylinder. The impressions cylinder squeezes the substrate against the plate to create a beautiful design.

Flexography is a versatile printing process that works superbly on paper and corrugated boxes. Its water-based, fast-drying, eco-friendly ink is also suitable for applying print on water bottles, plastic labels, and cartons.

3. Digital printing

Digital printing is another popular printing process. This new technology is fast, full-color, and requires no setup. It is a game-changer and makes things straightforward for small businesses, startups, or people who want one custom T-shirt.

Digital printing uses a full CMYK process similar to printing a photo with printers at home. It is sustainable because it only uses the ink required, minimizing waste.

There is also no limit to what one can do with colors, unlike screen printing, which requires putting up one color at a time. Businesses also do not have to worry about print designs because one can create colorful, vibrant designs.

The procedure is versatile and is not affected by the purpose of the print design number of T-shirts. Businesses needing to print small volumes, loads of colors like a photo, or print-on-demand services can opt for digital printing.

4. LED UV printing

LED UV printing is also a popular method that produces quality prints on substrates and takes less time to complete the application process.

The machine uses UV light rays to dry the ink while printing text or images on materials. Drying the ink is known as UV curing.

Ink instantly dries and does not sink into a substrate such as textile or paper—the UV printing process results in a sharp and clear image with vibrant colors.

The printing technique is also sustainable as it consumes less power than other techniques. It is also not limited to the kind of material to print. It can apply print designs on brochures, mugs, and phone covers. Its instant ink-drying capability makes its colors pop, transforming ordinary materials into luxury products.

Conclusion

Businesses venturing into printing should pick the best technique based on the current trends. This will help businesses produce quality prints and satisfy their customer’s needs.

This article discusses popular printing processes in the market. Some include offset, screen, digital, flexographic, and LED UV printing.

Also read: Screen Printing vs. Digital Printing: Which One Is Better?