Your excavator is a big investment. You will want to get the best performance from it, and the maximum life out of it. The key to keeping any excavating machine working well is regular preventative and periodic maintenance, and this is as true for small ‘backyard’ machines as for large industrial machines. This article explores the important parts of your machine to maintain and how to go about it.

Table of Contents

Why maintain?

Scheduled and preventative maintenance

Be familiar with your machine

Upper Structure

Undercarriage

Arm and Attachments

Final thoughts

Why maintain?

Regular maintenance is the single most important task in keeping your excavator running well, and neglected parts can mean a sudden breakdown and expensive repair. Many failures can be anticipated and prevented with a good maintenance regime and is well worth the effort.

Scheduled and preventative maintenance

For any type of excavating machine, the manufacturer will recommend that you conduct a periodic scheduled maintenance. The machine operating manual will provide guidance on when key parts need inspecting and changing. The engine oil and filter, additives, coolants and hydraulic fluid will all need to be changed at regular intervals as stated in the manual, and the machine should be inspected by a professional mechanic, trained in your type of excavator. Maintenance intervals are determined by operating hours, rather than by calendar, e.g. every 1000 hours of operation rather than every 3-6 months.

However, regular scheduled maintenance by a trained mechanic is only part of the solution, and there is plenty that an operator can do on a regular basis. Each day before starting the machine, and when stopping the machine for the day, there are checks that can be done and some simple actions that can save problems later. Create a checklist of things to check, keep a good record of maintenance conducted, when have parts been changed, when oils and filters were changed, what signs of wear and potential replacements can be seen.

Be familiar with your machine

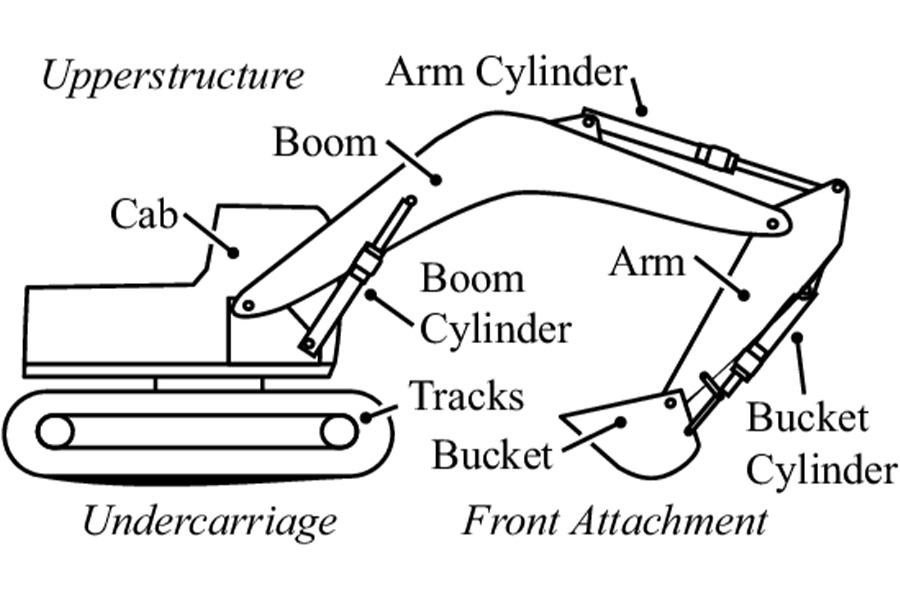

It is important to know your machine well. Even if you are not a mechanic, it is useful to understand the main parts of your excavator, what they do and how to keep them running smoothly. Your excavating machine can be described in three main parts: the upper structure (the engine, gearbox, fuel system, drivers cab and controls); the undercarriage (swing and track); and front attachment (the load bearing extension, boom, arm and bucket/attachments).

Each of these main components breaks down into more detailed parts with their own aspects of maintenance. We will look at each of these in turn, what to check, what problems to look for, how to properly maintain them.

Upper Structure

The upper structure is the main body of the excavator and holds the engine and fuel system, cooling system, gearbox, and driver’s cab and controls.

Engine maintenance

Diesel engines are reliable and hard working, and the typical choice for construction and agricultural machines. In most countries they must now conform to EPA standards for emissions and use ultra-low sulfur fuels, and so many excavators in the market will now specify an EPA certified engine. However, sulfur in fuel adds lubrication, so with lower sulfur fuel it is even more important to maintain engine oil levels. Each day when operating, look for dripping oil and oil leaks, check the oil level and top up if necessary. If you need to top up daily then there is probably a leak that needs fixing. Check the operating manual for any recommendations on additives and maintain additive ratios.

Fuel system

Because many of the machines in the market have EPA Euro 5 engines, using ultra-low sulfur diesel to reduce exhaust emissions, it is important to use the right fuel for your excavator. Check for leaks in fuel lines and gaskets and top up fuel as required. Some fuels may benefit from a lubricating additive, so check with the manual and/or the manufacturer for guidelines. Additives offer several benefits, from reducing corrosion and biocontamination, to boosting the cetane number.

Cooling System

Check the cooling system, radiator, oil cooler and condenser regularly, as neglect can lead to engine damage. Top up water and coolant, and replace the air filter during scheduled maintenance.

Gearbox

The gearbox does need a regular oil change and is often overlooked. Gearbox oil is typically changed at around the 1,000-hour mark, but check the manufacturer’s manual for their recommended service and oil change intervals.

Cab and Controls

Keep the cab clean daily, sweep out mud and dirt and wipe instrumentation and equipment. If your excavator is equipped with a controller system, this can provide important information on fluid temperatures and coolant levels. These measures can warn of possible problems, and some controllers may even be programmed to shut down the machine to prevent damage if warning messages are not heeded.

Undercarriage

The undercarriage on an excavator includes the tracks and assembly that move the excavator from place to place, and also the rotating / swing assembly that rotates the cab and upper structure through 360 degrees.

Daily, at the end of your work and when shutting down the excavator for the day, use a high pressure hose to clean out dirt and debris from the tracks and undercarriage. This will prevent any buildup and clogging in the undercarriage that will otherwise lead to premature wear and breakage, and parts replacement.

Once the undercarriage is clean you can more easily inspect it for excessive or uneven wear, damaged or missing parts. Especially check the following areas to ensure optimum track performance:

- Check for loose or missing bolts on the tracks and tighten as necessary.

- Check for bent shoes on the tracks, as a bent shoe can cause adjoining shoes to also bend.

- Replace bent or damaged rock guards and guides on the bottom of the tracks.

- Inspect the sprocket and drive at the rear of the tracks for oil leaks, and make sure no bolts are loose or missing.

- Adjust the track tension as necessary to avoid excess wear. Refer to the operating manual for recommended tension.

Arm and Attachments

The extending arm and attachments are usually in two sections, with the first section commonly called the boom, and the second section the arm, or stick. The usual attachment is the bucket, but can be replaced with other specialized fittings. Each section is controlled by hydraulic cylinders to extend and contract, push and pull.

Hydraulics

There are typically three hydraulic cylinders on a simple two section assembly, on the main boom, on the upper arm (stick), and between the upper arm and the bucket (or other attachment). Look for any leaks around the cylinders or below them. Check hydraulic oil levels on a daily basis and top up when necessary. Check the operating manual and change the hydraulic fluid and filter during a scheduled service. Although guides may differ for different machines on when to change the oil, most manufacturers would suggest changing the hydraulic fluid between 2,000-4,000 hours use.

Bushings and Pins

The bushings and pins allow hinged movement up the length of the arm and need to be greased daily to avoid unnecessary friction and wear and tear. Refer to the manual for each grease point and check manufacturer’s recommendations on quantity and grade of grease, but between one to three shots of grease is usually sufficient.

Bucket / attachments

Conduct a daily visual check of the bucket / attachments, looking for any cracks, worn or damaged pins or teeth and check that hydraulic hoses are tightly fitted and intact. Replace as necessary as damaged parts can reduce productivity.

Final thoughts

Ultimately, the key to good maintenance is to understand your machine and main components, and to be preventative rather than reactive. This article has covered each key part of your excavator and what you can do daily and periodically to watch for signs of potential failure, as well as some basics that are just good sense. Create a checklist of things to do and things to look for each day, when you first start the machine and when you shut it down at the end of the day. Keep records of maintenance and parts changed. Keep your machine clean, inside and out, as this will make checking for leaks and wear much easier. Remember, a good maintenance regime is well worth the effort and can help prevent costly breakdowns.