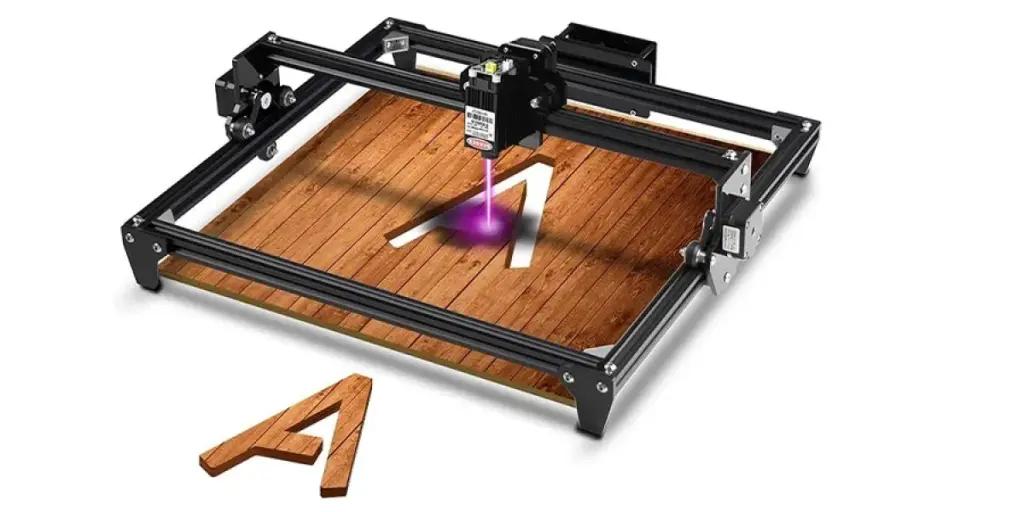

Engraving refers to a type of printing done on metal plates. Lines are cut on the metal where the ink will be held. A laser engraving machine uses laser technology to engrave on a metal surface or any other surface. They are widespread in industries that want to label/mark manufactured items and are known for their precision and smooth finishes. This article will look at everything businesses should know about laser engraving machines.

Table of Contents

Demand and market share for laser engraving machines

Factors to consider when buying a laser engraving machine

Types of laser engraving machines

The target market for laser engraving machines

Demand and market share for laser engraving machines

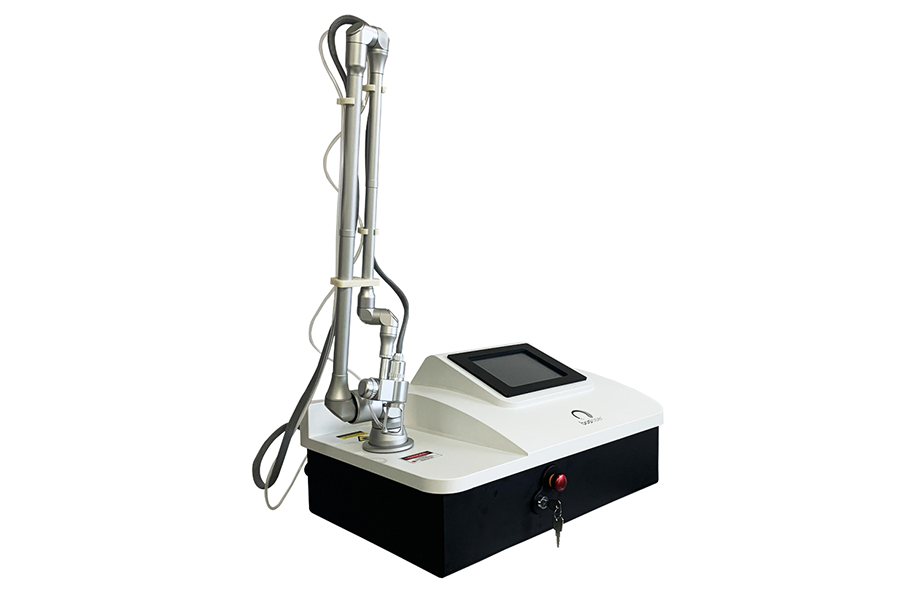

In 2020, the global market share of laser engraving machines was US$ 2.76 billion. The adoption of laser engraving machines is driven partly because of the benefits they offer in the automation of industries. The most notable of these is the medical field, which has recently experienced an upward surge in laser engraving technologies. Their reliability, effectiveness, and uniqueness of production are reasons that will drive their adoption even further.

Factors to consider when buying a laser engraving machine

Throughput of the engraving machine

It refers to parts processed per hour. The speed with which the engraving machine works will directly affect business sales, whether the volume of work is low or high. This, in turn, gives the business an edge in that it can offer lower prices to its customers.

Table size of processing

The table size determines the size of the object engraved. A smaller table size translates to smaller objects engraved, while a more extensive table will allow bigger objects to be engraved. The table sizes range from 300mm x 200mm while larger tables can be as big as 1600mm x 900mm. Depending on the object size businesses want to engrave, they can choose a suitable engraving machine.

Applicable material of the engraving machine

Engraving machines can work with several materials. Plastic, paper, metal, acrylic, and wood can be used during engraving. Businesses should consider the material they will be engraving before purchasing because engravers specialize in different materials.

Brand of key components

Before businesses purchase an engraving machine, they should consider well-established and reputable brands. This is to find quality and market-approved engraving machines. Besides this, a clear on-site demonstration of the engraver should be made to businesses to ascertain its effectiveness. Key components such as a working laser source and laser head, both manufactured by Aurora, and system configurations should work well.

Cost

The cost of acquiring an engraver determines what a business can and can not buy. Their prices vary from US$ 1,200 for a 100W laser engraving machine to US$ 15,000 for a 1000W metal engraving machine. In addition to cost, maintenance of the machine is critical as well. The frequency of care may have a considerable impact on a business. Because of this, businesses can look at whether the maintenance of the machine is something that is learnable or strictly requires a professional.

Availability of support features such as warranty

They are helpful, especially for engraving machines, because of the cost of operating one. Having a warranty is essential as it alleviates repair costs for some time. It also helps the business have a reliable source for maintenance and repair should it be required.

Types of laser engraving machines

There are several types of laser engraving machines based on their mode of operation. They are listed below.

Etching

Laser etching occurs when the laser beam comes into contact with the material and melts it.

Features:

- It uses high heat to melt the surface.

- The heated part expands and forms a raised mark.

- Has depths of no more than 0.001′.

Pros:

- It is faster than deep laser engravers.

- It provides more precise markings.

Cons:

- It can produce hazardous fumes.

- It requires specialized skills.

- It is costly to acquire and maintain.

Deep engraving

In deep engraving, a laser beam is used to make cavities on metals and other materials. The engraves are pretty deep, and the laser beam used is stronger.

Features:

- The laser produces a lot of heat, vaporizing the metal.

- Engraves are visible.

- The material is vaporized with each pulse of laser heat.

Pros:

- It offers a fast process.

- It produces reliable and clear engraves on the material.

Cons:

- It consumes a lot of energy, which translates to higher operational costs.

- It produces permanent cavities. In case of errors, the whole work has to be redone.

Ablation

Ablation refers to the removal of some material from a local area using a laser. It can lead to the removal of marks or the creation of permanent marks.

Features:

- C02 and fiberglass are used in the creation of the laser beam.

- It uses a fume extraction system to remove fumes so that the laser beam is not obstructed.

Pros:

- It has good monodispersity.

- It has a good particle size control mechanism.

Cons:

- Tumors can grow on the ablation margin.

- There can be inconsistency in the complete ablation.

The target market for laser engraving machines

Laser engraving machines are expected to grow at a CAGR of 7.5% until 2029. This will bring its market share to US$ 5.3 billion.

North America and Canada are expected to see substantial growth in their laser engraving machines markets because of strict health regulations on medical engraving equipment and surgical equipment. The Asia Pacific region will have the largest share of the global laser engraving machines market and is expected to continue dominating.

Conclusion

Engraving is an art that has been around for some decades. Known for the permanent marks that they leave, laser engraving machines have grown in popularity in many industries. Businesses can choose between etching, ablation, and engraving laser machines depending on the application required.