When forming sheet metal, the bending angle and the setup time are of the essence. Manufacturing companies can quickly and easily create sheet metals by automating the necessary processes to achieve the desired shapes.

For fabrication operations, sheet metal folders can significantly reduce labor, save time, and perform accurate processes, thereby boosting your potential in the market. However, determining which folding machine to pick is crucial to ensure an ergonomic operation. This guide will look at the various types of sheet metal folders that businesses should look out for and the factors to consider.

Table of Contents

Sheet metal folding machines on the global market

Tips to consider when selecting a sheet metal folder

Different types of sheet metal folding machines

Target market for folders

Final word

Sheet metal folding machines on the global market

The sheet metal machine market was valued at US$ 262.2 billion in 2019. It is projected to rise to US$ 408.31 billion by 2028, growing at a compound annual growth rate (CAGR) of 4.70%. Growth in this market is being driven by increasing demand in end-user industries such as construction, aerospace, military and defense, automotive, medical devices, oil and gas, and electronics.

In addition, rapid industrialization is also a major factor fueling the demand for sheet metal folding machines. As a result, more metal fabrication facilities are adopting the use of CNC machine tools to ensure enhanced operational efficiency and improved product quality.

Tips to consider when selecting a sheet metal folder

Applicable material size

Sheet metal folding comprises an extensive list of materials. Therefore, making a suitable selection of a machine means deciding on its folding length, width, and capacity.

The thickness of the sheet metal will depend on its intended purpose. Similarly, the width capacity of the folding machine should be about 80% of your production needs.

Otherwise, if you’re unrealistic in your machine folding thickness selection, you may end up with one that is too large for your core production.

Workpiece

When buying a sheet metal folder, you should first consider the workpiece. You should know the bed length and tonnage capacity. When doing your research, check the manufacturers’ performance graphs of the folders to better understand the machine’s capability.

Additionally, pay attention to details such as:

– Shape configurations (U, L, V)

– Motorized folding beam

– Back gauges length (the bigger the length, the better the performance)

– Tooling divide and clearance

Lastly, a folder machine, just like a press brake, is ideal if you want to fold large volumes of sheet metal.

Accuracy and material damage prevention

During the folding process, the blanking and hemming beam cutters do not move against the material, thus resulting in less or no surface damage. Another point of caution is the edges—they’re more exposed to damage when the sheet goes under the machine. To avoid damaging the edges, make sure you select a folder that guarantees the safety of the edges.

Finally, you should choose a machine whose bending radius for sheet metal folding is not too large or too small. A small bending radius can cause cracking or other distortions; a large bending radius can result in rebound. An ideal folder should secure an extremely accurate radius bend with almost zero tooling changes and a fast setup time.

Safety

This is a vital part of decision-making. The latest metal folding machines have LED function lights for visual functions and a 3-switch control foot pedal. The pedal stops the machine whenever it detects foreign materials during the folding process.

Further, sheet metal folding machines are highly automated to reduce the risk level to operators.

Different types of sheet metal folding machines

Manual sheet metal folding machines

Manual sheet metal folding machines operate primarily by folding the plate through the upper and lower blades into the required workpieces.

Features:

– Hinged base where the folded plates slide through

– Bending beam with a manual crowning system

– Folding beam angle

– Manual folding beam adjustment

– Clamping beam geometry

Pros:

– User-customized length

– Best suited for projects with a tight budget

– Suitable for short-term site folding processes

– Usable in any environment

– Convenient transportation

– Lightweight

– Fast cycle times and simple operation

– Consistent quality and shape of the parts produced

Cons:

– Possible deflection during plate bending

– Requires regular attention to the bearing and lubrication position

– Over-utilization could damage the blade

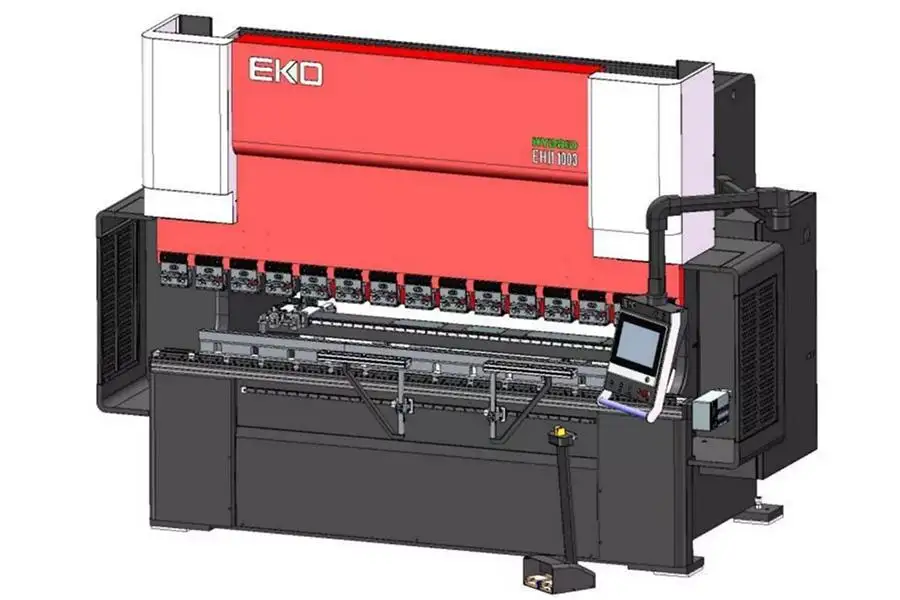

Hydraulic metal folders

Hydraulic metal folders use pumps and hydraulic cylinders as their motor to compress the metal into the die on the bending beam, completing the shape.

Features:

– Bending beam powered by hydraulic cylinders

– Valve system

– Hydraulic-operated clamping and bending beam for effective heavy-duty operation

– Switch control for beam operation

– Manual adjustment for folding angle

– Adopts torsion axis synchronization

Pros:

– Faster for an increased production rate

– Reduced costs as it can be used in-house

– Reduced metal wastage

– Versatile—can bend different materials and thicknesses

Cons:

– Possible fluid leaking if not properly tightened

– High temperatures can lead to the degradation of the fluid, depositing a sludge at the bottom of the cylinder

Computer-controlled sheet folders

Computer-controlled sheet folders’ upper ram compresses the metal sheet slightly while the hemming beam rotates upward to drive the sheet to be bent into shape.

Features:

– Electric drive design

– Motorized back gauge system

– Modifiable tool configuration

Pros:

– Durable

– Greater precision standards and attention to detail

– Higher volume production for faster turnarounds

– Improved workplace safety

– Optimal usage of materials

Cons:

– Expensive for operations on a tight budget

– Requires computer literacy to operate

Target market for folders

Sheet metal fabrication is largely used for industrial and consumer parts production as well as in specialist industries, including automotive, commercial airlines, HVAC, and electronics. Among these industrial verticals, the construction industry is expected to account for a significant share of the global revenue.

North America continues to dominate the sheet metal market to meet the high demand for this product from different end-user industries within this region. However, Asia-Pacific is expected to grow significantly owing to the different manufacturing environments in emerging countries within the region. Emerging economies such as India and China are also projected to contribute to consistent growth due to the increasing demand for automobiles.

Final word

The sheet metal machinery is consistently growing, making the fabrication process a walk in the park. Several factors, as aforementioned, have greatly contributed to the innovative designs of metal folders to improve the outlook and strength of the end product. Depending on your needs, implementing this technology will come in handy when boosting your production. Visit Alibaba.com to choose the sheet metal folders available.