Industrialization across the globe has created a demand for pressure vessels. A pressure vessel is a container designed to hold liquids or gasses at different specified pressures. There are many pressure vessels in the market, which complicates the selection process for businesses.

The article will look at the types of pressure vessels in the market, and it will discuss how to select the perfect pressure vessel to meet your business needs.

Table of Contents

Pressure vessels market

Types of pressure vessels

How to select pressure vessels

Conclusion

Pressure vessels market

Global pressure vessel market is currently valued at USD 47.1 billion. The market is expected to grow at a Compound Annual Growth Rate (CAGR) of 4.8%, crossing the USD 59.5 billion mark by 2027.

Requirements in end-user industries and advancing technologies in industrial machinery in developing economies are factors driving the expansion of the pressure vessel market. The global pressure vessel market is segmented by type, application, heat source, end-user industry, and region.

Asia-Pacific (APAC) is the largest market for pressure vessels and is expected to dominate due to growing industrial requirements for pressure vessels and technological advancements.

Types of pressure vessels

Atmospheric storage vessels

Atmospheric storage vessels store liquids, gasses, or other materials at atmospheric pressure. The pressure within the tank roughly equals the pressure around it. These tanks store and transport oil, gasoline, chemicals, and other substances.

They are made of materials such as steel, concrete, or plastic. The design and construction of atmospheric storage tanks must comply with industry and government standards to ensure safety and reliability.

Low-pressure storage vessels

Low-pressure storage vessels store liquids, gasses, or other materials at a lower than atmospheric pressure. The pressure within the tank is lower than the air around it.

They store liquids under pressure, such as liquefied natural gas (LNG), propane, and other gasses. They are cylindrical or spherical and are made of steel, aluminum, or plastic.

The design and construction ensure safety and reliability and prevent the release of hazardous materials into the environment.

High-pressure storage vessels

High-pressure storage vessels are containers used to store liquids, gasses, or other materials at higher than atmospheric pressure. The pressure inside the tank is greater than the air around it. High-pressure storage vessels store gasses such as hydrogen, natural gas, and other high-pressure gasses and liquids such as compressed air or propane.

High-pressure storage tanks come in various shapes and sizes and can be made of steel, aluminum, or composite materials. The design and construction of high-pressure storage tanks must comply with industry and government standards to ensure safety and reliability and to prevent the release of hazardous materials into the environment.

High-pressure storage tanks are equipped with pressure relief valves to prevent over-pressure situations.

Autoclaves

Autoclaves are pressure vessels used for sterilization and disinfection. They utilize high-pressure steam to kill microorganisms, bacteria, and other pathogens on instruments, materials, and surfaces.

Autoclaves are used in medical facilities, laboratories, and industrial settings to sterilize equipment, tools, and other items. The steam temperature and pressure used in autoclaves are carefully controlled to eliminate all microorganisms effectively.

The vessel consists of a chamber where the items to be sterilized are placed, a door for loading and unloading the chamber, and a control system that monitors and regulates the temperature and pressure.

Reactor vessels

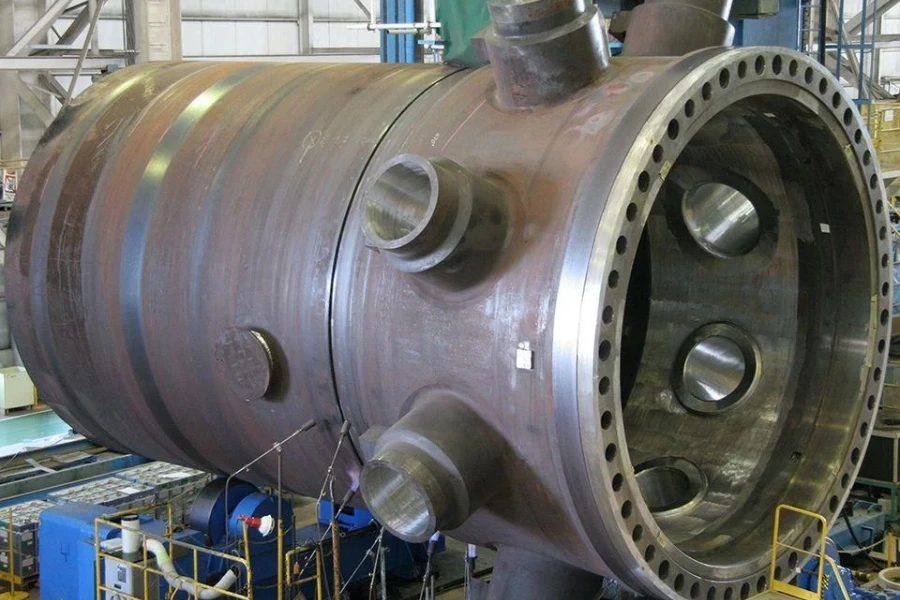

Reactor vessels are specialized containers used for chemical reactions and processes. They are designed to withstand high temperatures and pressures from chemical reactions.

Reactor vessels are made of stainless steel, titanium, glass, or ceramics. They are used in various industries, including chemical synthesis, petrochemical processing, pharmaceutical production, and renewable energy.

Reactor vessels are equipped with various controls and systems, including temperature control systems, pressure control systems, and agitation systems, to regulate the conditions inside the vessel and ensure a safe and controlled reaction.

How to select pressure vessels

Design and operating pressure

Design pressure is the maximum pressure the vessel can withstand without failure. The design pressure must be higher than the maximum operating pressure to allow for fluctuations and safety margins.

Selecting a pressure vessel with a design pressure appropriate for the intended application is essential. Different industries, such as pharmaceutical and petroleum refineries, have different designs and operating pressure requirements. Choosing a pressure vessel that meets your design and operating pressure needs is important.

Size and capacity

The size and shape of the pressure vessel must be appropriate for the intended application and allow for easy installation, operation, and maintenance. During selection, consider the space available to install the pressure vessel and choose a size that fits the space. However, the size and capacity must match your pressure needs.

Material

The material used to construct the pressure vessel must be suitable for the intended application and must be able to withstand the design pressure and temperature. Common materials used for pressure vessels include steel, stainless steel, aluminum, and composite materials.

High-pressure vessels require steel for strength and safety reasons. Choose a pressure vessel with materials that are compatible with your pressure needs.

Safety features

When selecting a pressure vessel, it is important to consider safety features to ensure safe operation and prevent accidents. Common safety features are pressure relief devices, burst discs, pressure gauges, and vacuum relief devices.

Safety features help prevent disasters and mitigate damage when disasters occur. Ensure the pressure vessel selected has the proper safety features.

Budget

When selecting a pressure vessel, it is important to consider the budget to ensure it is cost-effective and fits within the available financial resources. Some budget-related factors to consider when selecting a pressure vessel include material cost and assembly cost. However, the budget should consider the safety and quality of pressure vessels.

Certification

Different countries and regions have different requirements that govern the certification of pressure vessels. Pressure vessels can pose a hazardous danger and must be certified to ensure safety. Ensure your pressure vessel is certified by the relevant authorities for the safety of your business, production site, and human personnel before purchasing.

Conclusion

The demand for pressure vessels is driven by the growth and expansion of various industries that require storage and processing of liquids and gasses at elevated pressures. Some of the industries that have a high demand for pressure vessels include the oil and gas industry, the chemical industry, the food and beverage industry, the pharmaceutical industry, and the power generation industry.

Choosing a pressure vessel will be easier if you follow the considerations outlined in this step-by-step guide. For quality pressure vessels, visit Alibaba.com.