Labeling machines are essential to any business as they allow products to be precisely and efficiently labeled with information like product names, ingredients, and warning labels. However, choosing these machines in the market can be challenging since there are many factors to put into consideration.

This article will explore the key factors to consider when selecting a labeling machine, as well as provide information on the types of labeling machines so your business can make the best decision.

Table of Contents

Overview of the labeling machine market

Selection tips for labeling machines

Types of labeling machines

Conclusion

Overview of the labeling machine market

Massive demand for labeling equipment is causing a surge in the market size. The labeling machine market was worth US $3.4 billion in 2020, and the figure is expected to grow to US $4.9 billion, growing at a compound annual growth rate (CAGR) rate of 4.8% from 2021 to 2031.

The main contributor is the emergence of e-commerce. Many online businesses are coming up, and each of them requires appropriate labels. Using quality inks, prints, and many display options leads to an enormous need for labeling machines.

Selection tips for labeling machines

Rate of application

The rate of the application, or the speed of applying the ink or print on the product, is essential to consider before buying labeling equipment. The machines get ratings in terms of product per minute (PPM).

The higher the PPM rating, the faster it can apply labels. The machine is, therefore, suitable for labeling bulk items. Equipment with a low product-per-minute rate is suitable for small-scale labeling.

Some machines can regulate the speed and halt the application process without the operator stopping the machine. They can, however, be expensive because of their advanced features.

Material compatibility

Businesses need to think about the extent of materials to which the machines can apply the labels. Different materials on which the operator can apply labels include paper, foil, or film.

Businesses should acquire labeling machines that suit the type of material of the product that will be labeled.

Labeling machine configurations

To make the labeling machines offer various labeling options. Modern labeling machinery is programmed in different configurations to accommodate different application methods.

In-line labeling machines have more configurations than semi-automatic machines. Rotary machines have the most configurations to withstand vigorous labeling applications.

Compare machine features

When choosing labeling machines, checking their features, such as roll capacity, product dimensions, standard features, and options, is crucial. Other aspects to weigh include the price and the freight costs.

Awareness of the equipment’s specs makes it easy for businesses to know what type, speed, or function of labeling machine they should acquire.

Machine flexibility

Labeling machines can create different shapes and sizes, allowing one to operate one machine at different production lines. Other machines have fixed parts, therefore saving on acquisition and maintenance costs.

Productivity and operation size

How many products does the business make that require label application? What is the size of the operation plant? These are crucial questions that businesses should ask when buying labeling equipment.

Machines rated for high production and massive operations are suitable for large businesses. Smaller labeling machines are appropriate for low production levels and small-operation plants.

Types of labeling machines

1. Wet glue labeling machine

Wet glue labeling machines are a popular choice for labeling products. The machines use wet glue to apply the label, providing a strong bond that can withstand different packaging and products.

Pros:

- The machine produces labels with high accuracy and precision

- The machines allow for the application of decorative label designs

Cons:

- Wet glue labeling machines require more time to set up and use

- Wet glue labeling machines tend to be more expensive than other labeling machines

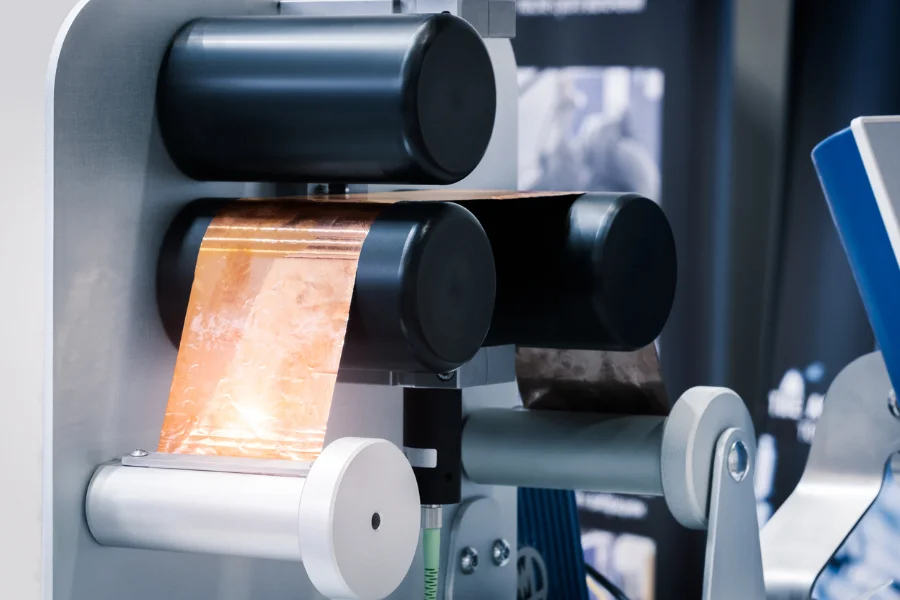

2. Hot melt labeling machines

Hot melt label applicators use hot melt adhesive to attach labels to products. The machine melts the glue for application on the surface, and the label sticks after it cools down. The machines work well for wraparound labels, such as a container body.

Pros:

- The application process is fast and efficient

- Produces a strong bond that holds up well with different types of packaging and products

Cons:

- The machine needs time for the glue to heat up

- The adhesive is difficult to remove if there is a mistake

3. Heat seal label applicators

These machines use heat to melt an adhesive on the back of a label, which then adheres to the product or packaging.

Pros:

- The label application process is fast and efficient

- They apply labels to the products with high speed and accuracy

Cons:

- If the heat seal temperature is too high, it may damage the product or packaging

- The machine is not suitable for application on products with dents or intricate shapes

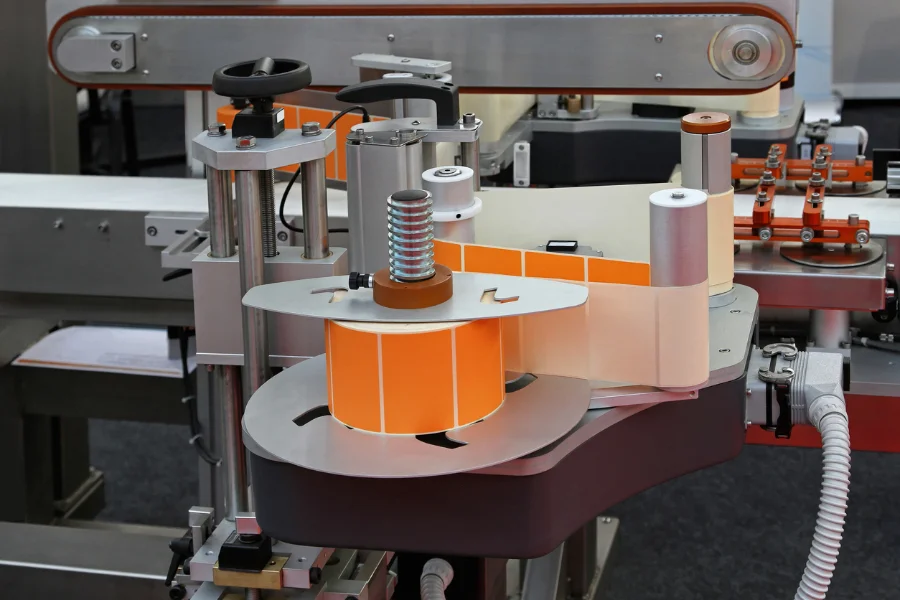

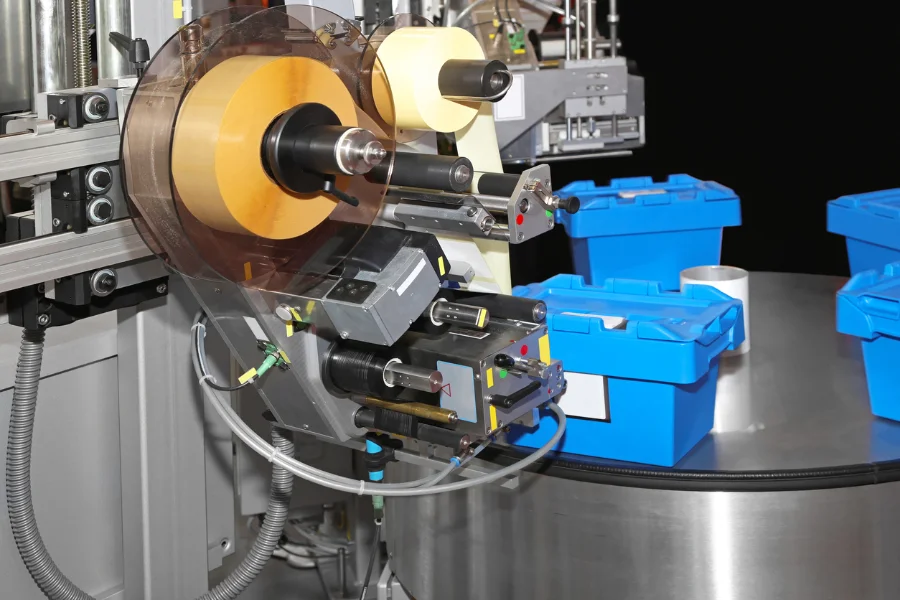

4. Print and apply labeling machines

Print and apply machines are automated labeling machines that print the labels on demand and then apply them on the products or packages as they pass through the production line. They print information such as product names, descriptions, barcodes, and prices of products.

Pros:

- The machines are designed to work quickly, applying labels at a high speed

- The automated nature of print labels reduces the risks of making errors or mistakes

- They are flexible, meaning one can use them on various applications

Cons:

- Print and apply machines depend on computers and other electronic components, which can fail or break down, disrupting the production process and resulting in downtime

- The label type is limited to certain types of labels

Conclusion

By adhering to these points, businesses can know what type of labeling machines to procure. Choosing the right equipment will help the businesses to adhere to industry-specific labeling standards and improve their brand image.

Here is another helpful article to read on the latest packaging machinery industry trends to look out for.