Wood lathe machines are used to hold a piece of wood, turn it, and process it. They are commonly used in woodworking industries to make different patterns and shapes on wood. Wood lathes play an essential role in industrial wood sculpture. The application of wood lathes is enormous in the manufacturing industry and the furniture industry.

Table of Contents

Wood lathes: market share and demand

Key factors to consider when purchasing a wood lathe

Types of wood lathe machines

Target market for wood lathe machines

Wood lathes: market share and demand

The size of the woodworking machinery industry in 2021 was $4.62 billion. Emerging trends include consumers preferring prefabricated wooden houses to stone houses. As a result, the demand for wooden prefabricated houses will boost the sale of wood lathe machines. More specifically, cross-laminated timber is preferred because it has fewer emissions of C02. Also, wood lathes reduce material usage and are efficient.

Key factors to consider when purchasing a wood lathe

Before a business buys a wood lathe, there are several factors it should consider.

Size and weight

The size and weight of the wood lathe will determine the size of projects a business can handle. Mini lathes have 10” between the centers. They are suitable for small projects such as small sculptures. Big lathes such as the full-size lathe will have 40” between the centers and are ideal for table legs and other large projects. Regarding weight, a mini lathe will weigh between 20 and 30 lbs. The midi lathe weighs 1000 lbs, while the full-size lathe weighs 1500 lbs. Businesses should consider the size and weight of wood lathes based on the orders they are handling.

Base

A sturdy base is essential when turning material because it will minimize vibration when the wood is spinning. Having an unstable base could make woodturning unsafe for the operator, so businesses should consider a heavy solid base made of cast iron.

Power and speed

The power and speed of a wood lathe are determined by its motor. Some motors produce ⅛ hp while other motors can generate 3 hp. The more the power of a motor, the larger the workpiece it can work on.

Tailstock and headstock

The headstock spindle is threaded to allow use with accessories such as chucks. A business should ensure that this thread is standard in the event of upgrading the lathe. The tailstock is a rotating spin that ensures the workpiece is at the center. It should be locked securely before working on a workpiece.

Security

Security refers to safety while working around a wood lathe machine. For instance, it should be possible to secure the workpiece on the spindles firmly, and a power switch should be easily accessible in case there is a need to turn off the machine. In addition to this, safety glasses and earmuffs are essential for the eyes and ears protection of the operator.

Tool rest

The tool rest is essential when turning the tool as it provides tool adjustment to the turner. When it is being moved, the machine has to be locked in position. The tool rest should be 10”-long and preferably made of cast iron to minimize vibration.

Accessories

Accessories of the wood lathe include a tool rest, faceplates, chucks, and dust chutes. A business should consider whether the wood lathe machine they intend to buy offers these accessories or whether they are purchased separately.

Types of wood lathe machines

There are several types of wood lathe machines from which a business can choose.

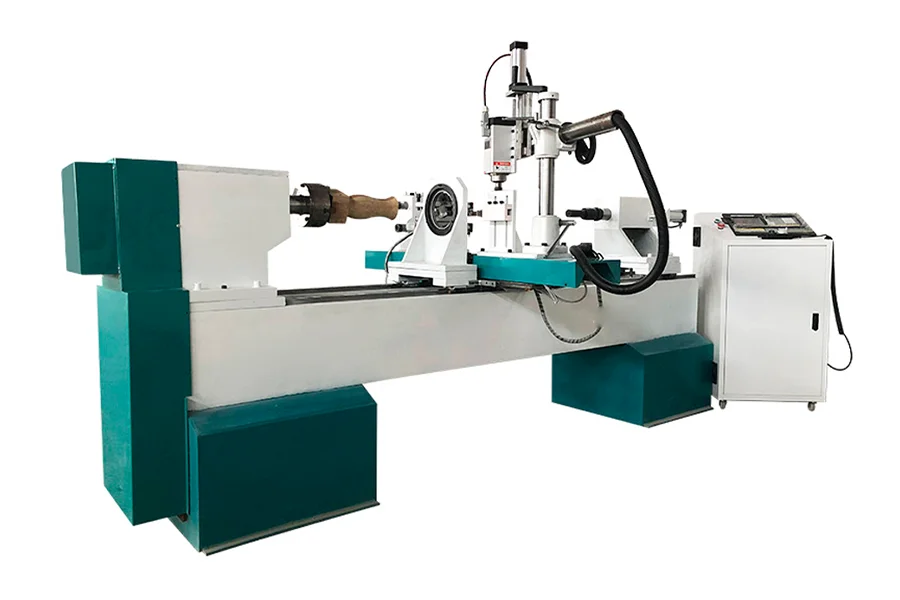

Full-size wood lathe

As the name suggests, the full-size wood lathe is the largest type of wood lathe.

Features:

- It has a lathe speed of between 300 to 500 rpm.

- It has an in-built tool rest, a functional headstock for increased rotation, and a tailstock for precision.

- It has a wide DBC (distance between centers) of 45” and SOB (swing overboard) of 15”.

Pros:

- It is suitable for working on big projects/workpieces.

- It has a powerful motor.

- It can work on a wide variety of projects.

Cons:

- The precision of the work depends on the skills of the operator.

- There is a lot of idle time in between operations on a workpiece.

- It is expensive.

Midi wood lathe

The midi wood lathe falls between the full-size and mini wood lathes.

Features:

- It has a benchtop wood lathe design.

- It has an SOB of 12” and a DBC of between 12” and 20”.

Pros:

- It can work on larger workpieces without occupying more space.

- It is cheaper than the full-size wood lathe.

- It is easy to use.

Cons:

- It cannot be used for complex designs.

- It is not compatible with some of the mini lathes.

Mini wood lathe

The mini wood lathe is the smallest type of wood lathe.

Features:

- It has an adjustable speed between that ranges from 700 to 3200 rpm.

- It comes with accessories such as chucks, dust chutes, faceplates, and 2 tool rests (4 ½” and 7”).

Pros:

- It is suitable for starting wood lathing.

- It is best for micro-projects (projects under 6”).

- It is cheap to acquire and maintain.

Cons:

- Its projects cannot be further refined on other types of lathes.

- It is only limited to small projects.

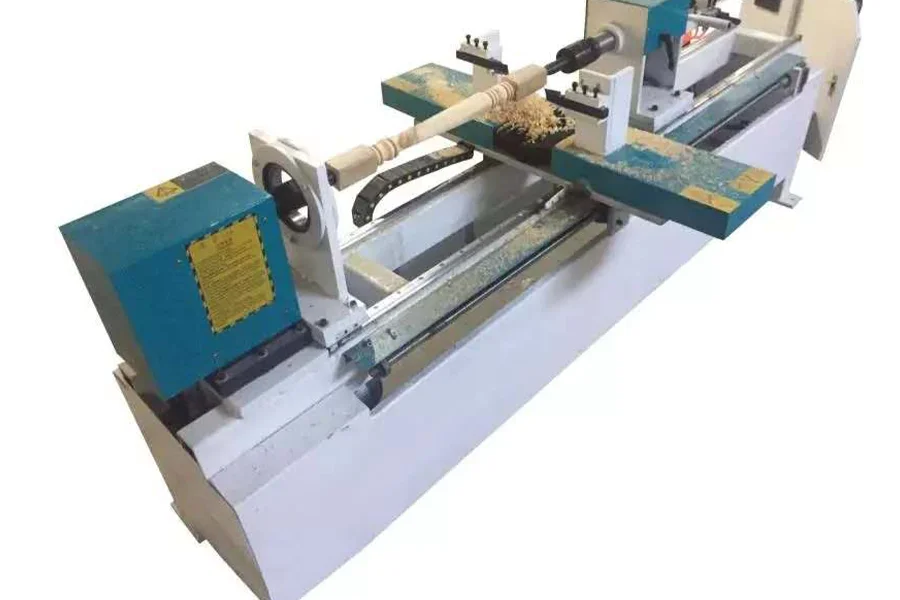

Center wood lathe

The center wood lathe is the most common wood lathe used.

Features:

- It has a drive center that transfers power from the motor to the workpiece.

- It has a gear shaft that accurately grasps the main shaft speed.

Pros:

- It is very accurate.

- It can invert the workpiece without failure in concentricity.

- It supports different operations without failure in concentricity.

Cons:

- It has an imperfect cutting rate if a revolving center is not used.

- It lacks stiffness.

- It becomes monotonous to use over time.

Target market for wood lathe machines

The woodworking machinery industry is projected to grow to $6.05 billion by 2028, with a compound annual growth rate of 3.9%. The North American region holds the largest share of wood lathes (34%), followed by the Asia Pacific region (30%), with 50% of purchases being midi lathe machines. The Asia Pacific region is expected to exhibit the largest growth rate due to increased population, households, and changes in consumers’ needs. The North American region will experience substantial growth as well.

Conclusion

The wood lathe industry can be lucrative but only to the businesses that know how to invest. This is why this guide has explained the factors to be considered when buying lathe machines and the types of lathe machines available. Besides this, the wood lathe machines section on Alibaba.com can help offer further information.