Machinery automation is one of the many trends in the manufacturing sector expected to disrupt the industry. Automation helps to enhance efficiency, increase production precision, and reduce downtime, among other perks.

This article discusses how machinery automation will change the manufacturing sector. Keep reading.

Table of Contents

Automation market overview

What is automation in manufacturing?

How automation will change the manufacturing industry

Conclusion

Automation market overview

Machinery technology is evolving, signifying that the process of manufacturing is changing. Many factories are focusing on using advanced equipment to make production faster and easier.

The global industrial automation market size is estimated to be worth $205.86 billion in 2022. Its valuation is projected to be worth $395.09 billion in 2029, exhibiting a CAGR of 9.8%

The driving factor for the growth of the automation market size is the availability of wireless 5G network connectivity. High demand for automating systems has also grown because of the adoption of industry 4.0 in many factories.

With a high global demand for products and raw materials, the rate of production has to increase. Manufacturers can not only depend on human workers and robotics, hence opting for automatic machines in their plants. In this article, we look at how manufacturing is changing with the adoption of automation.

What is automation in manufacturing?

In manufacturing, automation is replacing or enhancing human labor with machines in the production process. The main aim of automation is to improve efficiency by increasing the rate and lowering the cost of production.

There are three types of automation.

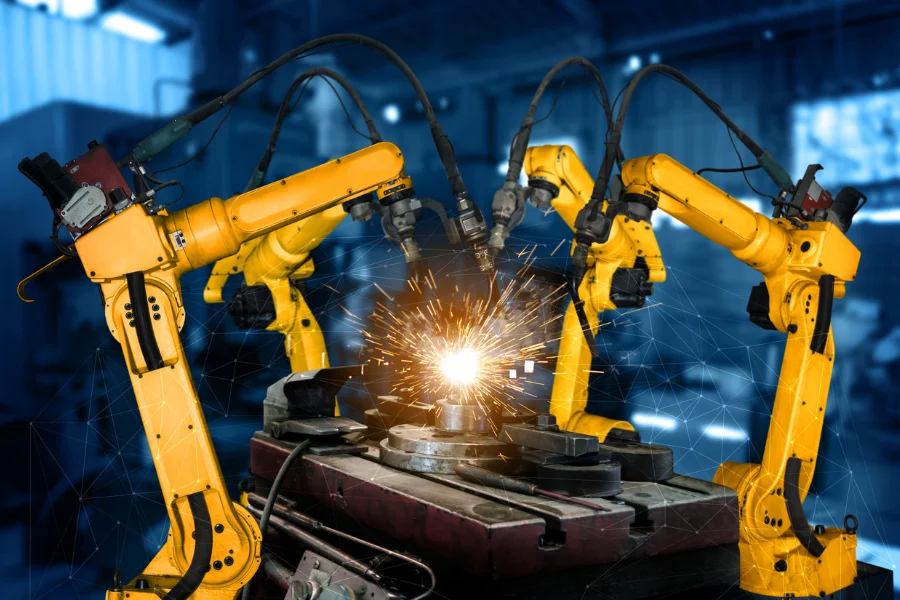

Fixed automation

Fixed automation, also called hard automation, does only one task, such as a welding machine. Most of its programming is contained within the individual machines. The speed and sequence of processes are determined by the equipment or the production line.

After a production run is complete, a changeover in the production process is not possible. If any changes are needed, technicians will require to shut down the whole production line and manually swap the equipment. It would thus lead to a high cost and lengthy downtime.

Programmable automation

Programmable automation can produce several dozens to thousands of units at a time. On top of that, this type of automation enables the manufacture of different types of parts and products.

Programming is required for batch production and may take a long time. Manufacturers can also install new programs to make new products.

Flexible automation

Flexible automation incorporates the features of both fixed and programmable automation. Despite its versatility, it is designed to work with a limited number of products, which gives the option to use it for more than one product without having to spend a lot of time reprogramming.

How automation will change the manufacturing industry

Reduced production time

Time is one of the most important elements in any manufacturing industry. For tasks to be completed, it is an advantage if manufacturers take fewer working hours. By automating industrial machinery, the time to produce different products is reduced because the speed that machines take to complete tasks is shorter than the time taken by human workers.

Robots are also capable of completing difficult production tasks within a short cycle. Even if a factory has highly productive workers, some tasks will have to be dedicated to machines. In production lines that handle heavy tasks, it can take workers long hours to complete them.

Machines with high horsepower numbers can perform them quickly and efficiently. For instance, when lifting and arranging bulk loads, robots can save a lot of work hours.

Ten times higher production precision

Precision production is the result of designs that require highly accurate components made into functioning parts. A study found robots to be ten times more precise than humans. Engineers come up with designs of parts and leave the rest of the job to machines to make them to the right specifications.

The machine used to manufacture the designed components is known as a CNC machine. CNC machines cut pieces of metal materials or sheets into the model from the design in the computer.

Precision manufacturing is also faster than welding and machining elements by hand. Moreover, it saves on the costs of outsourcing designing services and acquiring new parts.

Automation is advancing even further with the emergence of 3D printing. 3D printers optimize manufacturing processes because they design parts and print them in one take.

Manufacturers can maximize production by using simpler and cost-effective methods such as CNC machining and 3D printing.

30% increase in higher-volume production

Machines are capable of producing, packing, and stacking huge volumes of products when working correctly. Because of automation, production efficiency increases by 30%. Therefore, manufacturers can leave machines operating day and night without the need for monitoring.

Furthermore, manufacturers can introduce new items from their production lines. Through offline programming, machines can be incorporated with new codes that allow them to make a new type of product.

Lower operating costs

One of the best advantages of automation is that it reduces the costs of production. Automation technologies can monitor energy consumption and assist manufacturers to make better decisions on how to cut costs.

Automation also helps to reduce labor costs. Depending on the type of work, robots can produce a work rate of 3 to 5 people.

Other costs manufacturers can cut are raw material costs by reducing waste. Waste material can be recycled using technology from complex machinery.

Increased workplace safety

Some of the manufacturing processes, if machining is not an available option, are extremely dangerous for human workers. Through automation, manufacturers can allow machines to handle hazardous operations. This enables human workers to deal with less risky tasks.

For instance, in factories dealing with the manufacture of industrial chemicals, machines can perform the tasks of mixing toxic formulas to limit the chances of chemical poisoning.

Less human error and better product quality

Humans are prone to making mistakes. A study found that 23% of total downtime results from human errors that affect the business’s infrastructure and processes. An average manufacturer experiences 800 hours of downtime yearly, with a minute of downtime costing a $22,000 loss.

In contrast, machines are capable of performing tasks more accurately than humans. Engineers program the machines with codes that maintain consistency. When humans do the same tasks over and over again, they get bored and make errors. Machines perform repetitive tasks without making mistakes, maintaining product quality throughout the production process.

Conclusion

Efficience, precision and profits are what automation has to offer to manufacturers. Even though many people claim automation will cause a lot of job losses, this trend not only brings new job opportunities but also enhance safety in the workplace by undertaking the most repetitive and hazardous tasks. This article has discussed the impact of automation in manufacturing.