Laser annealing is one of the new technologies used in fiber optics and electronics, automotive, test tools, and the medical industry for the identification of medical instruments. The method changes the color of different materials with regard to the temperature of the heat used. Colors obtained through laser annealing vary from yellow, green, blue, brown, and red. Laser annealing technology comes with a range of benefits.

In this article, we are going to discuss everything you need to know about laser annealing technology.

Table of Contents

What is laser annealing technology?

Benefits of laser annealing

Principles of laser annealing

How laser annealing works

Applications of laser annealing

How to select a laser annealing machine

Conclusion

What is laser annealing technology?

The laser annealing technology is a quick localized heating and cooling process that results in a change of color of the material being worked on at a certain temperature. The colors vary between red, yellow, and green based on the temperature subjected to the surface being marked. There is low distortion on materials during the annealing process thus producing high-quality products.

The following are the four types of laser annealing machines and examples of materials they can mark.

– UV lasers – metals, glass, plastics, and paper

– CO2 lasers – textiles and paperboard

– Fiber lasers – rubber and plastics

– YAG lasers – thin metal sheets and substrates like aluminum

Benefits of laser annealing

– The process is fast so it saves time and creates fewer distortions on the materials.

– It retains the original properties and shapes of the workpieces.

– The process is efficient and clean as it does not require chemicals.

– It is cost-effective because it produces high-quality products with less waste of materials.

– It is highly productive due to increased output.

Principles of laser annealing

Laser annealing is basically exhibited through the thin-film interference occurrence while giving metals a colored look. When light is shone on an annealed workpiece surface, it is cleaved into two waves. The waves are split by differential reflections.

The first reflection is seen when the superficial oxide layer is hit by light rays. Afterward, the second reflection comes about when the light passing through the oxidized layer reaches the unmodified substrate. Both reflections have waveforms that are out of phase; thus have different wavelengths. The waves destructively or constructively interfere with each other to produce specific colors for the workpiece. The constructive interference gives the material its main color.

A fraction of passing light is absorbed by the oxide layer. More light will be absorbed if the layer is thicker and less is reflected simultaneously. As a result, the surface increases its darkness with the increasing thickness of the oxide layer. In this case, different laser parameters are managed to attain various beautiful colors.

How laser annealing works

Annealing is generated when laser annealing equipment locally heats a metal until it is almost at its melting point. The lattice structure changes during this process where the generation of oxide on the surface of the workpiece is shown in the aspect of various annealing colors. The colors appear at around 200oC because they are temperature-stable.

Higher temperatures revert the lattice to its standard state. In this case, the mark disappears; thus, the finished surface remains fully preserved. After the process is complete, the material begins to cool showing the intended mark. Generally, laser marking is only enabled by metals that change color when subjected to heat and oxygen. Examples of these metals are titanium and steel.

Applications of laser annealing

Below are examples of laser annealing applications:

– Electronics and fiber optics

– Aerospace, automotive, and defense industries

– Pharmaceutical industries for medical implants

– Test tools like laser marking systems by Toshiba

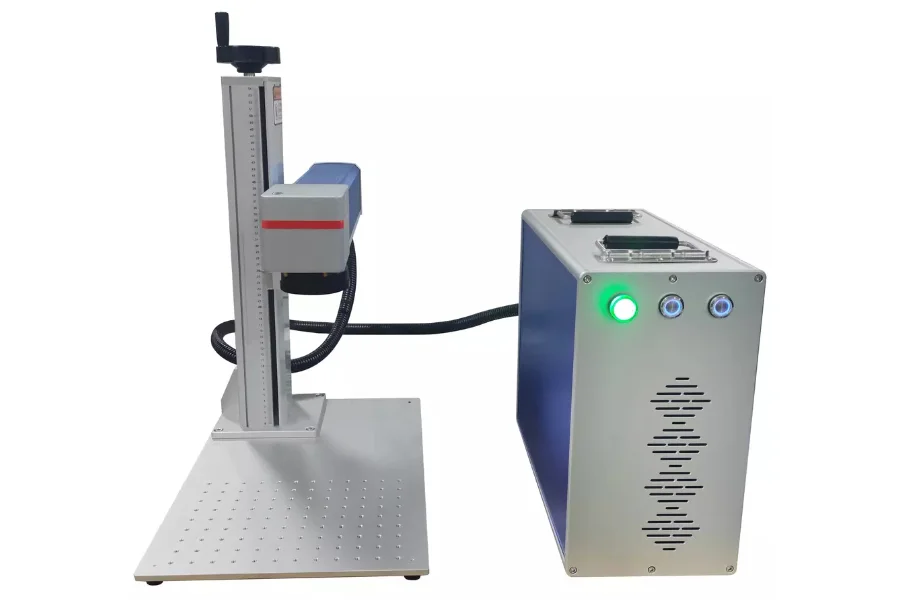

How to select a laser annealing machine

1. Material to be marked

Materials being marked determine the model of the laser marking machine suitable for a buyer’s projects. This is because various materials have different optic properties. A single laser machine interacting with different materials produces varied results. For example, there is extra work when marking transparent or translucent materials compared to when using lasers to mark opaque workpieces. This is a result of light passing through the translucent materials which scatter the light and thus make laser annealing difficult. Also, the color of the material affects laser marking. Black workpieces are easier to mark because they absorb all light.

2. Cost

Buyers should consider acquiring laser machines that last long while performing at peak efficiency. Depending on their budget, they should take into account the initial cost of the laser equipment, its peripherals, and the kind of maintenance during its service time. For instance, a fiber laser machine’s cost ranges from USD 3,500 to USD 28,500, while a CO2 laser marking machine falls between USD 4,500 and USD 70,000. Therefore, buyers should choose machines that operate for about ten years with minimal maintenance. The functionality of laser machines should go hand in hand with their affordability and reliability.

3. Accuracy

Various industries have different laser annealing accuracy requirements. The laser beam penetrates into the material surface for about 20 to 30 microns. This results in minimal changes to the workpiece, which influences the precision and accuracy of the markings. The level of accuracy is determined by factors like the beam spot size on the material and where a small spot produces a more precise marking. Also, thermal control and the optical system quality have to be in check to consistently produce accurate results.

4. Marking speed

There is a variance in the marking speed of several models of laser annealing equipment. They are differentiated by either being low-end or high-end models. The factors that affect a machine’s marking speed include the model quality, marking sizes, and the material type to be marked. For instance, a UV laser has a marking speed of about 9000 mm/s. A good-quality laser provides an average speed to mark a material like a key fob within 30 seconds. And there are higher-quality lasers that can complete the same task in less than 5 seconds. Additionally, laser marking takes more time than etching, but does not harm the material surface and produces ineffable marks.

Conclusion

Laser annealing technology has evolved over the years and currently offers the greatest benefit—improved accuracy. The heat treatment process alters the mechanical and physical properties of certain materials. For instance, metals increase ductility, decrease hardness, and get rid of internal stress. Buyers need to understand the annealing process, its advantages & disadvantages, and factors to consider when choosing the laser machines for their laser marking tasks. To acquire high-performance laser annealing equipment, visit Alibaba.com.