Table of Contents

The CNC router and the laser engraver: The differences

Definition

Method

Principle

Applications

Conclusion

The CNC router and the laser engraver: The differences

Both the CNC router and laser engraver are computerized engraving machines, meaning that both require a computer to control the engraving process. Thanks to this, many people mistakenly believe that the CNC engraving machine and laser engraving machine are the same thing. In fact, there are many differences between these two types of machines.

Before going into too much detail on the definition, method, principles, and applications of these two engravers, one point must be made clear. The CNC engraving machine can be referred to as CNC router, CNC routing machine, CNC engraver, or CNC carving machine, while the laser engraving machine refers simply to a laser engraver.

Definition

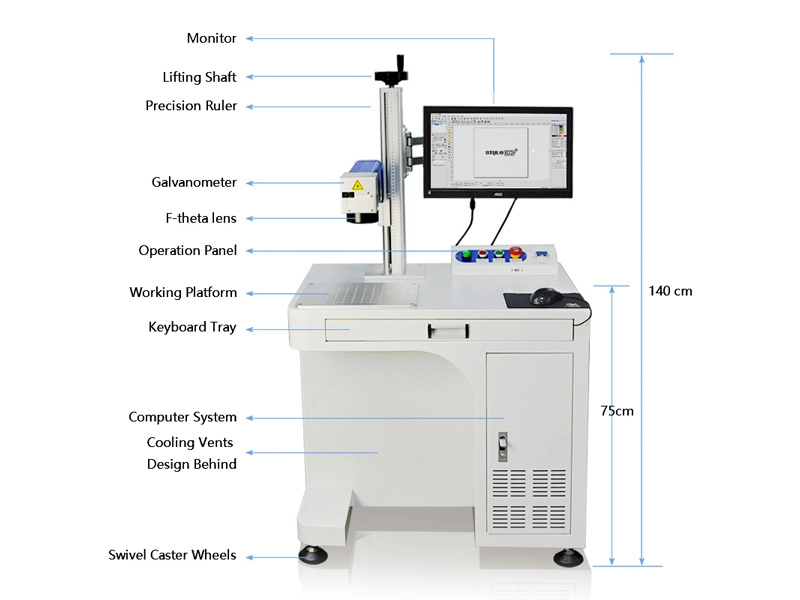

Laser engraving

Laser engraving is based on numerical control technology, with the laser being the engraving hardware. The numerical control system controls the laser head and the motor to move the direction and motion of the laser beam, mirror, lens, and other components, meaning that the laser’s focus can be moved on the X, Y, and Z axes. The material being processed instantly comes into contact with the laser. At this point, the melting and gasification caused by the laser’s heat achieves the purpose of physical modification and engraving.

There is no physical contact with the surface of the material during laser engraving, meaning that it is not affected by mechanical movement, the surface will not deform, and the material generally does not need to be fixed. This also means that the elasticity and flexibility of a material does not impact the engraving process, making it convenient for soft materials. Laser engraving machines offer high processing precision, high speeds, and a wide application field.

CNC engraving

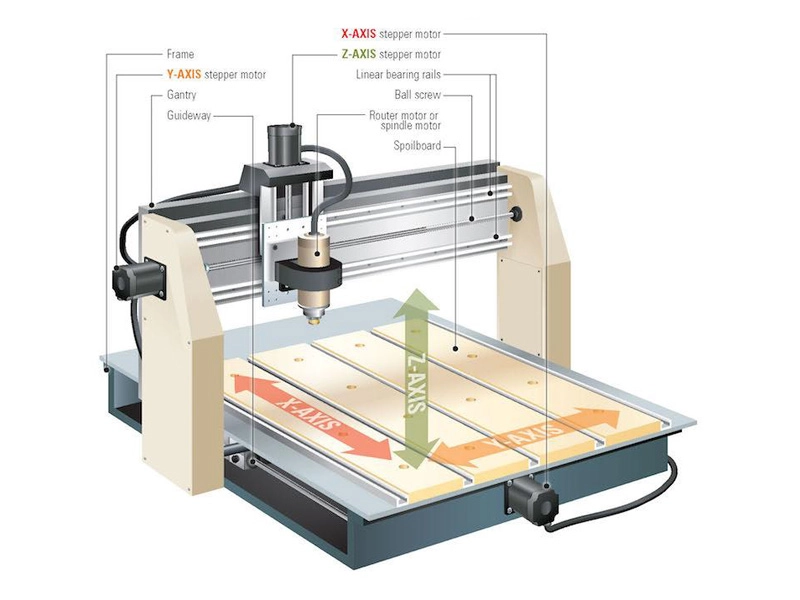

Computer Numerical Control (CNC) is an automated machine tool equipped with a simple program control system. The control system logically processes the program using control codes or other symbolic instructions, and then decodes it so that the machine tool can move and process the engraving.

The CNC carving machine is relatively simple. Through the control of the computer numerical control system, the machine automatically selects the appropriate bit and tool, and then engraves it along the X, Y, and Z axes of the machine tool.

Method

A simple process must be followed to engrave with either the laser or CNC engravers. The engraver must first be connected to a computer. Once this is done, the user can typeset the prepared picture file or path diagram on the computer, and then import it into the engraving machine. However, although both engravers use numerical control systems, they work differently and their mechanical structures also differ.

Laser engraving

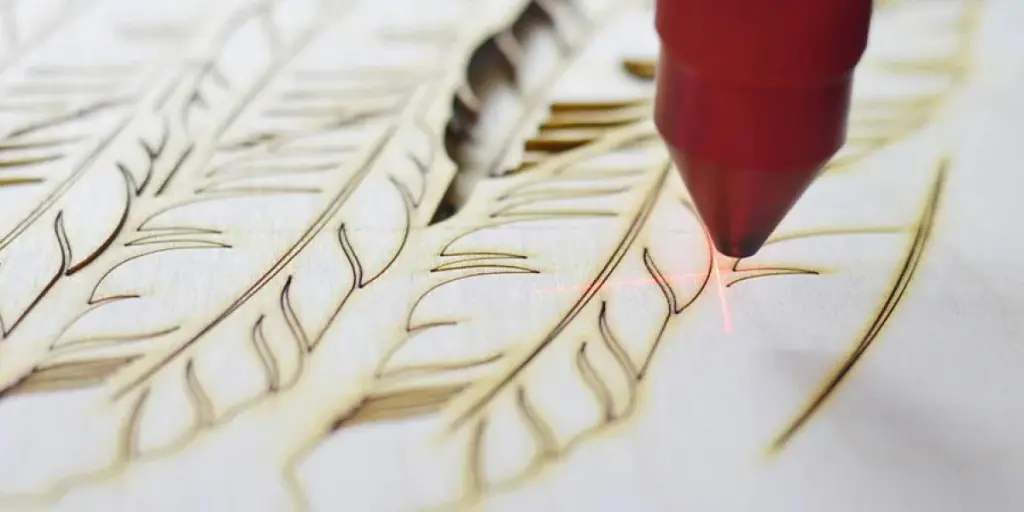

A laser engraver uses a laser, which modifies the material through high temperatures. Therefore, similarly to as can be seen in combustion processes, different combustion chemical reactions will appear on different materials during the work process — each varying depending on the melting point of the material and creating differing cutting effects. Additionally, the cutting process will produce an oily smoke and smell.

Laser engraving is a type of non-contact etching, which protects the surface of the engraved material from being scratched. In addition, the laser beam is very thin, so the slit is small and suitable for precision cutting.

CNC engraving

A CNC router relies on the spindle and bit to work, which, similarly to using a drill bit, can produce dust during the cutting process but will not produce the smoke and smell produced by a laser engraver.

The cutting seam of the CNC engraving machine depends on the diameter of the router bit — of which there are many types. Different router bits are used for different materials.

Principle

Laser engraving

A laser engraving machine emits a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece until it reaches the melting point or boiling point. At the same time, the high-pressure gas runs coaxially with the beam to blow away the molten or vaporized metal. As the relative positions of the beam and the workpiece move, cutting marks will appear on the material, thereby starting the engraving process.

CNC engraving

A CNC engraving machine relies on the high-speed, rotating engraving head, which is driven by the motor spindle. The processing material, which is fixed onto the worktable, can then be cut by the cutting tool, which is configured according to the processing material. Various 2D and 3D designs can be realized by creating embossed graphics or text on the computer and then engaging the automatic engraving operation.

Applications

Laser engraving

The laser engraving machine can only perform cutting and shallow carving on an object’s surface, such as shadow carving to create portraits on marble tombstones.

Laser engravers can be roughly divided into non-metal laser engraving machines (CO2 laser engraving machine) and metal laser engraving machines (fiber laser engraving machine):

- Non-metallic engraving machine: These can be divided into ordinary engraving machines and non-metallic laser marking machines. Non-metallic laser engravers are suitable for materials such as wood, paper, leather, cloth, plexiglass, epoxy resin, acrylic, wool, plastic, rubber, ceramic tiles, marble, crystal, jade, bamboo products, and other non-metallic materials.

- Metal engraving machines: These can be divided into metal laser marking machines, and all-in-one metal engraving and cutting machines. The applicable materials for engraving with metal laser engravers include metal sheet, acrylic, plexiglass, glass, cloth, leather, paper, bamboo and wood products, film, canvas, etc.

CNC engraving

The CNC engraving machine has a very wide range of applications and can be applied to various fields and industries. To this end, it is suitable for engraving and cutting various materials (except for materials with low melting points).

The CNC engraver can be cut or make reliefs, and can be applied to furniture, musical instruments, handicrafts, molds, signs, souvenirs, and processable materials including wood, foam, acrylic, plastic, PVC, ABS, stone, imitation stone, marble, aluminum-plastic panels, copper, aluminum, and other soft metal materials.

Conclusion

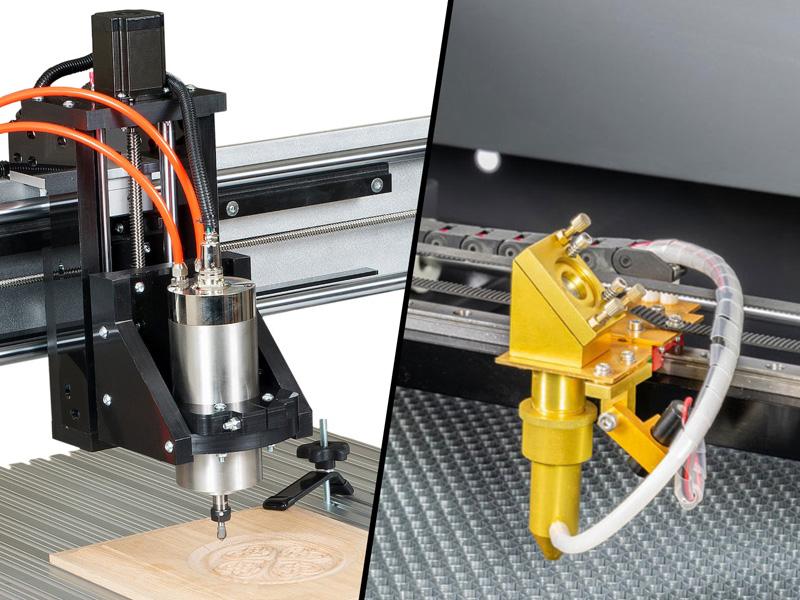

The biggest difference between the laser engraver and CNC engraver is that the laser engraver machine’s tools are a complete set of optical components, while the CNC router machine’s tools are a collection of parts from various entities. The laser etching machine uses a laser’s high energy to cut or engrave the material, while the CNC carving machine uses a high-speed rotating cutter head to cut and engrave the material. This means that the process that the engraved object is submitted to differs between the two methods.

Having said that, there is a degree of interconnectivity between these two methods, as the laser engraving machine can work as a CNC carving machine and the CNC engraving machine can also be equipped with a laser head for engraving.

Thus, depending on the usage and cut you require for your engraving projects, you may purchase a laser engraver, a CNC router, or a hybrid of the two.

Source from stylecnc.com

Disclaimer: The information set forth above is provided by stylecnc independentiy of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller andproducts.