With the heavy intelligent manufacturing transformation, China’s equipment manufacturing industry has seized the “Window Period” of rapid development, and the CNC laser equipment market also ushered in rapid growth. According to CCTV Finance and Economics, China’s laser equipment market has grown more than six times in the past ten years, with a compound growth rate of 21.5%. It is estimated that the market scale will exceed 80 billion yuan, and the export scale will reach 10 billion yuan by the end of 2022.

The unprecedented market space and opportunities have attracted more and more companies to rush into the laser cutting track, including comprehensive laser companies with the layout of the whole industry chain and multiple flowering of various application markets, and many professional laser companies focusing on the laser cutting segment track.

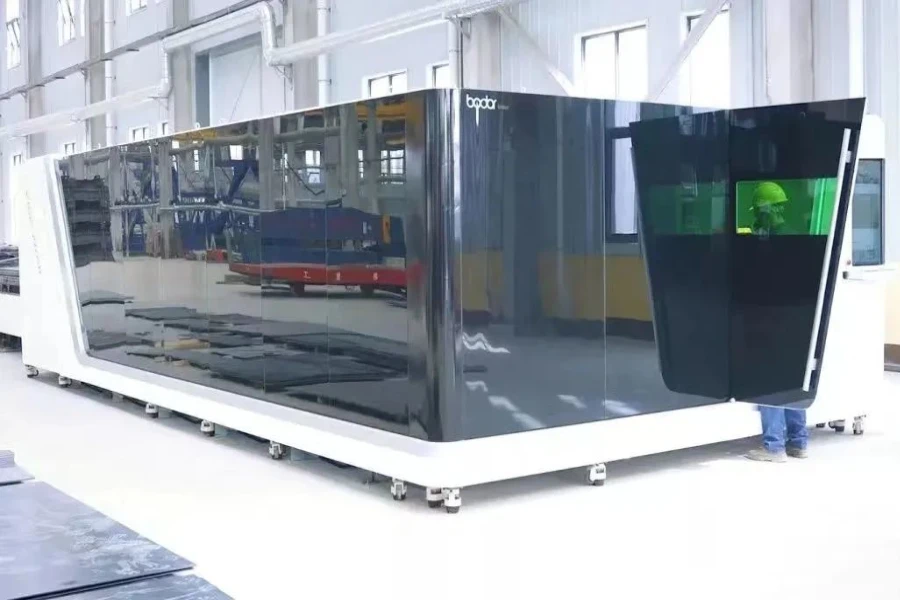

The Bodor Laser in Shandong is one of the typical representatives of the latter. Since its establishment, Bodor Laser has always adhered to focusing on the single category of laser cutting machines, achieving full coverage of the 1.5 kW to 50 kW power range, including three series such as flagship, performance, and economy, and launched different products such as high-end plate, large panel, medium and thin plate, heavy pipe, plate and tube integration to meet the diversified needs of customers.

Founded in 2008, Bodor Laser has stepped up in the tide of the times. Its main business is a global intelligent laser solution provider integrating the research and development, production, sales, and service of laser processing application products. In just over ten years, it has been riding the tide of domestic substitution and writing the story of national brands.

The industrial transformation has given birth to the era of 10 kW, and the precision of Bodor Laser has stepped on the pace of the era.

Over the past decades, the laser cutting industry has undergone a series of changes. At first, the low-power fiber laser cutting machine was used mainly in hardware, kitchen and kitchen utensils, advertising, and other industries. With the continuous improvement of laser power and technology, the thickness and processing efficiency of laser processing material have improved significantly. The industries such as sheet metal processing, fitness equipment, rail transit, auto parts manufacturing, high-end mechanical equipment manufacturing, rail transit, aerospace, and others have also introduced laser cutting technology step by step. And the laser cutting market has ushered in an outbreak period.

In particular, with the continuous development of domestic new energy vehicles, aerospace, rail transit, and other high-value-added industries, the domestic market demand for high-power laser cutting machines is increasing. While providing many market opportunities, it is also constantly guiding the upgrading of the laser cutting industry. In 2017, the 10 kW laser cutting machine came into being under the market demands for higher laser power and greater cutting efficiency. Although the stability of new products was questionable in the market at that time, their powerful performance was recognized quickly by the market, and the laser-cutting market soon entered the era of ten thousand watts.

With the era, Bodor Laser seized the opportunity to follow up quickly. After a period of technical preparation, Bodor Laser sold the first 10 kW device in December 2019, which sounded the clarion call of Bodor Laser, the global leader in 10 kW products. In 2020, the world’s first 40 kW laser cutting equipment developed by Bodor Laser made a stunning debut, and the world’s first 30 kW laser cutting machine was paid for and delivered in November 2020.

Of course, high power is not the only pursuit of the laser cutting industry. To fill the gap in the industry and provide more personalized services for customers in different segments, Bodor Laser has successively developed mortise and tenon series laser cutting machine products that combine the quintessence of China’s millennium with modern laser technology, magnetic levitation laser cutting machine with faster speed and higher accuracy, laser scanning and cutting machine that subverts the industry concept, 22 kW/24 kW laser cutting equipment for the subdivided processing field, and so on. With a full grasp of the laser cutting market segment, various laser cutting machines under Bodor Laser have blossomed in many places, forming a complete product matrix and boosting the laser industry to develop towards the trend of high power, high efficiency, and high intelligence.

Developing new products in the industry and scanning and cutting innovation industry patterns

As mentioned above, China’s laser cutting industry is also undergoing continuous upgrading and transformation in the context of industrial upgrade and enterprise transformation. It is noteworthy that Bodor Laser launched a new category in the industry – laser scanning cutting machines in February 2022. With a new laser application concept, this new category of products subverts the unchanged processing method of laser cutting since its inception, upgrades the static spot cutting to the dynamic spot cutting (each cutting 1 m, the light-spot travels 30 m), significantly improves the absorption efficiency of processed materials to the laser energy, and forms three main advantages such as speed doubling, thickness doubling, and no fear of high reflection.

The laser scanning and cutting machine (SCAN) is an epoch-making product produced under the perfect integration of the BodorPower laser, BodorGenius laser head, BodorThinker bus system, BodorCutting process package, and other products under the original environment of Bodor Laser. Compared with ordinary laser cutting machines, the laser scanning cutting machine with the same power has achieved a leap of 100% increase in cutting thickness and 180% increase in cutting speed, eliminating the power attenuation caused by cutting high reflective materials. The product director of Bodor Laser pointed out.

Since its release, the scanning and cutting machine has attracted the follow-up reports of many domestic authoritative media, captured numerous customers’ favorable comments, and led competitors to imitate to set off a new upsurge in the industry.

Firmly adhering to the globalization strategy that the sales volume ranks first in the world for three consecutive years

It is undeniable that the domestic laser-cutting market has entered the dilemma of No Increase in Incremental Income after experiencing rapid growth and fierce price competition in the past. The sales volume of many companies increased gradually, but the income was flat or even declined. In this case, the overseas market was a Battleground for all companies to gain profits. China’s laser equipment, with high quality, excellent stability, and high-cost performance, has also been accepted and approved by the global market.

According to the CCTV financial report, China’s laser equipment has been accepted and approved by the global market. Since 2019, China’s export of laser equipment has begun to exceed the import value, while the export value in the first ten months of 2022 has reached 9.09 billion yuan, up 27% gradually. According to statistics, the top export-ranking countries of China’s laser processing equipment in the first ten months of 2022 include the United States, South Korea, Russia, India, Brazil, etc.

It is worth mentioning that China’s laser manufacturing caused some concerns of overseas and local companies because of its too strong competitiveness while it has had achievements overseas. In October 2022, India’s Directorate General of Trade Relief (DGTR) announced that it would launch an anti-dumping investigation on industrial laser machinery and equipment imported from China for cutting, marking, and welding in response to the complaint of Sahajanand Laser Technology (SLTL), an Indian industrial laser manufacturer. SLTL has publicly announced that industrial laser machines imported from China have caused substantial damage to India’s domestic industry. According to statistics, Chinese brands represented by Bodor Laser account for more than 70% of the Indian laser-cutting market.

Of course, the impact of Chinese laser companies on the global application market is not limited to the vicinity of China. Take Bodor Laser as an example – after more than ten years of development and layout, Bodor Laser has more than 2000 employees from more than 20 countries and regions such as the United Kingdom, Italy, Canada, and Australia, and has achieved 24-hour uninterrupted service. Whether in Chicago, Tokyo, Paris, Seoul, Mumbai, etc., Bodor Laser has local employees who can provide localized services at all times. After more than ten years of market development, Bodor Laser’s 10 kW laser products have been sold to more than 180 countries and regions and recognized by more than 40,000 metal processing companies. The sales of 10 kW products have also successfully exceeded 2,000 sets.

According to the customs export volume data, the export data of Bodor Laser has been the first for seven consecutive years since 2015. In the past three years, Bodor Laser has won the world’s top sales for three recent years with annual shipments of 2,672 sets (2019), 3,727 sets (2020), and 5,190 sets (2021).

R&D investment has increased 30 times in the past 7 years based on one institute and two centers

The outstanding market performance is inseparable from Bodor Laser’s continuous investment in technology research and development. For ten years and more, Bodor Laser has laid out the product Power+Innovation two-wheel drive pattern and invested many human and material resources in independent research and development. The data shows that the R&D investment of Bodor Laser has increased by nearly 30 times from 2016 to 2022.

To consolidate the foundation of R&DA and develop high-quality laser cutting machines, Bodor Laser has created One Institute and Two Centers formed by the research and development center, innovation center, and laser application research institute. Among them, Bodor R&D Center, one of the most authoritative R&D platforms in the industry, has a large number of top talents, constantly subverts innovation, and continues to promote the rapid development of laser technology in China. Bodor and CAE Member have jointly established an academic expert joint innovation center to provide scientific guidance for the long-term development of the laser industry and cultivate many outstanding talents in the industry. The Laser Application Research Institute, headquartered in Shanghai, is the most cutting-edge institution focusing on the research and application of high-end technology in the industry, realizing the rapid market application of many black technologies and empowering the laser industry.

In addition, Bodor Laser has also set up overseas technical institutions in Germany, the United States, Japan, India, and other countries to integrate the core technology and talents of the global laser industry and bring more possibilities to the product and industry of Bodor Laser. Supported by One Institute and Two Centers and four major overseas institutions, Bodor Laser has made leapfrog progress in technology research and development, product iteration, and others, and repeatedly filled the gap in China’s laser cutting technology.

Summary

In 2016, Bodor Laser broke through the core technology of laser and developed advanced laser manufacturing application technology and equipment, included in the 13th Five-Year Plan national scientific and technological innovation plan. In December 2021, the 14th Five-Year Plan manufacturing development plan pointed out that China should vigorously develop intelligent manufacturing equipment, including advanced laser processing equipment, such as ultrafast lasers.

In fact, the current domestic laser companies with relatively large scales are still generally engaged in the general industrial laser market. The technical barriers are relatively low, but the application space and demand are huge, and easy to occupy the market share quickly. However, it cannot ignore that the transformation and upgrading of the traditional domestic manufacturing industry have reached a critical stage. With the export of 10 billion yuan approaching, China has vigorously promoted the development of the high-end equipment manufacturing industry, and the growth space of high-end laser equipment has become more and more.

Bodor Laser believes that companies with strong Product Power+Innovation Power can maintain strong competitiveness in the more fierce international battlefield in the future. Bond Laser, which continuously focuses on laser cutting single-category products, will continue to strengthen product research and development, provide better products and services for global metal processing companies, and create a new business card for China Intelligent Manufacturing. Make China Intelligent Manufacturing Famous in the World!

Source from ofweek.com