Internal combustion engines have generators called alternators that generate electricity for the vehicle while recharging the battery. Knowing how these alternators function might seem like rocket science, especially for fresh retailers entering the business.

This article highlights the importance of car alternators, how they work, and how to know when the alternator is starting to malfunction.

Table of Contents

The market size of the automotive alternator industry

What are alternators, and how do they work?

How long do alternators last before replacement?

Four reasons for alternator wear

Five signs of a faulty alternator

How to test for malfunctioning alternators

Tips for replacing a faulty alternator

Final words

The market size of the automotive alternator industry

The increasing usage of electrical power in automobiles due to the rise in electrical devices is expected to propel the market for car alternators. The growing demand for vehicles also significantly contributes to the industry’s growth.

According to experts, the global automotive alternator market will expand by US$ 3.29 billion at a 6.08% compound annual growth rate (CAGR) from 2022 to 2027. The car alternator industry is driven by the surging demand for commercial vehicles and passenger cars. Asia Pacific registered the highest market share in 2021, and experts estimate it will continue its dominance.

What are alternators, and how do they work?

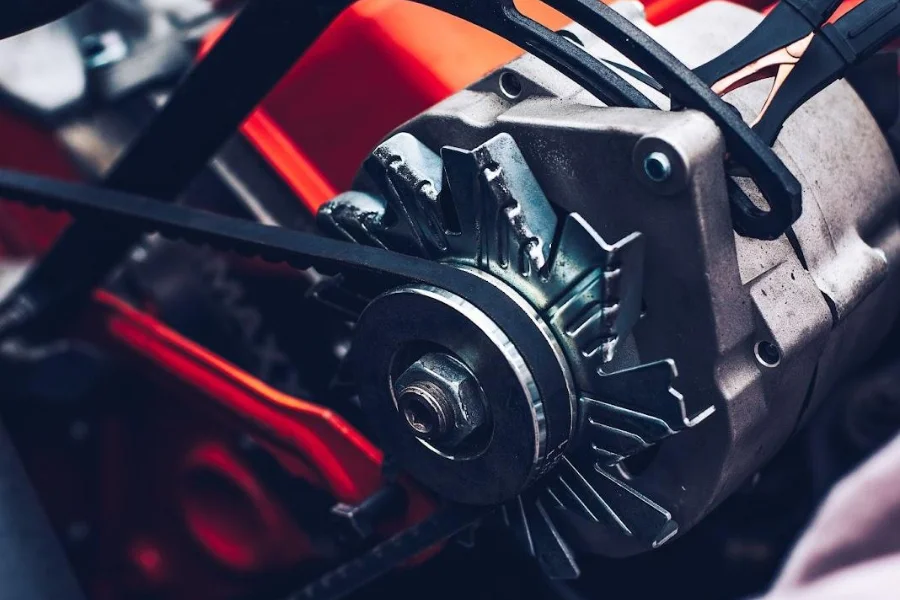

An automotive alternator, located at the front of the engine, is a generator that converts the engine’s mechanical energy to electricity. The equipment also helps recharge the vehicle’s battery.

Going deeper, alternators utilize electromagnetic induction to generate alternating currents. Then, they push this voltage through some built-in diodes to transform it into direct currents.

The generated current passes through a voltage regulator before reaching the car or its battery.

True to their name, voltage regulators ensure the current remains stable, preventing overheating or overloading.

However, alternators are not immune to wear and tear, engine environment, and external environmental damage. Eventually, they will need replacements, regardless of how well consumers maintain their vehicles.

How long do alternators last before replacement?

Alternators are not weak electrical components. On the contrary, they usually offer impressive lifespans, removing them from items needing preventative maintenance. However, car owners must replace them at specific intervals.

In addition, climate, usage, and other external influences can affect an alternator’s lifespan. As a result, the equipment can last anywhere between 60,000 to 200,000 miles, depending on these factors.

In some cases, owners may replace their alternators every six years, regardless of their condition. However, that’s an extreme and expensive practice. Instead, owners can opt for an annual charging system inspection.

Using a multimeter, retailers can check the battery while inactive and examine the condition of the alternator.

Four reasons for alternator wear

Accessories

Cars with extra accessories needing heavier electrical draws can stress an alternator, causing it to wear out fast. For example, air suspension pumps require a good amount of current, mainly when a leak in the system forces them to work harder.

Other equipment, like booming stereo equipment, can showcase a taxing power draw. Intense off-road lights also require a good amount of juice.

Bearings

One common cause of alternator failure is when bearings wear out. Over time, these components become weak, rendering them unable to support the rotor.

Excessive pressure can also make bearings wear out faster. For instance, the timing belt may be excessively tight, causing this issue. Also, engine fluids leaking onto the alternator can catalyze quick wear out.

Defrost and A/C systems

Usually, drivers would use defrost systems frequently in cold climates to ensure the car’s temperature remains comfortable. As a result, the vehicle’s A/C compressor, electric window defrosters, blower fans, and heated steering wheels/seats undergo heavy use.

Likewise, hot weather conditions see frequent use of fans and air conditioning. Unfortunately, using defrost and A/C systems heavily will cause the alternator to wear out quickly.

Battery

Faulty batteries that can’t sustain a reasonable charge or ones nearing the end of their lifespan can cause issues for alternators. Such situations force the alternator to double the effort to keep the battery charged and ready to go.

Five signs of a faulty alternator

Fluctuating headlights

Faulty alternators can only produce irregular output. As a result, headlight fluctuation is one visual indication of this issue.

Faulty alternators can cause the headlight output to flicker between dim and bright or stay fainter than usual. Also worth noting is that interior lights are not exempted from this problem.

Erratic electronics behavior

Reduced voltage conditions from faulty alternators can affect a vehicle’s entire system. In addition, onboard computers and electronics won’t receive enough power, causing unpredictable performance.

So when power windows start misbehaving or the radio is experiencing static, it could point toward a faulty alternator.

Unnecessary dashboard warning lights

Although a low battery warning light is the first thing you’ll see for faulty alternators, other signs may light up for problems that don’t exist. For instance, the seat belt sign would glow even when the driver has the seat belts on.

Audible growling noise

Alternators with worn-out bearings will generate an audible growing noise when spinning. Retailers can open the hood and listen attentively while the engine is running.

If bearings are causing the issue, car owners will hear them over the engine’s sound. Sometimes, it may be audible enough to hear from the vehicle’s interior.

Acrid burning smell

While not a common sign, alternators will generate an acrid burning smell at the end of their lifespan. It may result from burned-out coils or brushes or the timing belt slipping over the dragging pulley.

How to test for malfunctioning alternators

Testing an alternator also requires checking the battery. So the first step is getting a battery tester to confirm whether it can hold a charge or needs replacing.

After recharging or replacing the battery, owners can check the alternator’s output with a multimeter. However, they must set the multimeter’s knob to a value greater than 15 on the DC volts area.

An idle, fully charged battery should show results between 12.6 and 13.2 volts. But, the alternator must surpass that voltage, especially when the engine is running.

More importantly, owners should also clean and tighten all wiring connections (particularly the main battery terminals) during these initial stages. Also, they must inspect the timing belt, ensuring it has enough tension to rotate the alternator’s pulley without slipping.

For the preliminary test, ignite the engine and grab the multimeter’s terminals. Place the positive terminal on the positive battery terminal and the negative to negative. Then, check the voltage output value displayed on the multimeter.

An idle alternator should place somewhere between 14.2 and 14.7 volts. So, anything higher indicates a problem with the equipment.

But, if the voltage sits in the 14 range, turn on some accessories, like headlights and radio. The slightly heavier load should drop the alternator’s output slightly, but not below 13.

However, if the readings go below 13, the alternator is not supplying enough charge to handle the activated accessories. In addition, owners can also check the wiring connecting the battery and alternator to ensure everything is in perfect shape, without cuts or visible corrosion.

Tips for replacing a faulty alternator

Disconnect the battery

The first thing to do when replacing an alternator is to break the battery connection. Failing to do this may cause issues with live wires, leading to more severe problems, including giving a shock.

Disconnect the wires

After disconnecting the battery, it’s time to remove all wires from the alternator. Try labeling them before loosening them to avoid making the wrong connections once you are done.

Remove the timing belt from the pulley

Timing belt removal depends on the vehicle type. Owners can find screw-type or rod-end-type tensioners (for applying tension). For loosening the tensioner, they should grab a socket or wrench and turn until enough tension escapes, making removing the belt possible.

Unscrew all bolts

Next, remove all the bolts connecting the alternator to the bracket. Again, remember that the number of bolts may differ according to the model.

Reverse the process

After inserting the replacement alternator, it’s only a matter of reversing the previous processes. Next, tighten the bolts, reapply the timing belt, increase the tension, and connect all wires.

Final words

Alternators are essential components for generating electricity in vehicles. As a result, faulty ones can cause mishaps like dashboard lights turning on for no reason and low current generation.

Car owners may decide to change alternators every six years, but it’s best to perform tests before making replacements. Sellers can follow this guide to learn how to detect faulty car alternators and how to replace them.