There is a wide range of techniques available that printers can choose from when it comes to t-shirt serigraph printing (also known as screen printing). This article will focus on six of the top serigraph printing techniques for personalized t-shirts.

When screen printing is done in large quantities, it becomes much cheaper and easier, because the more t-shirts produced, the lower the comparative time required to prep the screens.

For now, let’s take a look at the different serigraph printing methods one can use, so you can find out the right method to suit your needs.

Table of Contents

Plastisol

Water-based printing

Discharge serigraph

CMYK printing

Foil printing

Dye sublimation serigraph

Find the right serigraph printing method for you

1. Plastisol

The most common and cheapest ink for t-shirt printing

Plastisol is a very robust type of ink that holds over time. It is oil based, so removing it requires chemicals. Due to that, it is less eco-friendly than some other alternatives.

Nevertheless, plastisol is still the most popular ink, as it can be printed on both light or dark colored t-shirts. Anything printed over a light base will pop and shine a lot more, but each color will add an extra cost. So ultimately, the more colors you choose for the t-shirt design, the more expensive the print gets.

You can also print designs with a large number of colors using plastisol. Depending on how many stations the screen printer has and their automated or hand presses, you can choose either 8, 10, or 12 colors. Designs that have up to three colors are usually the most affordable.

Backer colors are not needed when printing on white t-shirts, because the print will already be on a light color; this is definitely advantageous. Another plus of printing on lighter colored t-shirts is that since less ink is used, the t-shirt will have a softer feel. For example, a single color over white will feel softer and use less ink compared to a multi-colored print of the Rolling Stones logo.

A downside to using more ink is that the prints tend to crack as they get older. If you are worried about your t-shirts getting cracked over time, then the next method is probably a better choice.

2. Water-based printing

Uses inks that are water-based

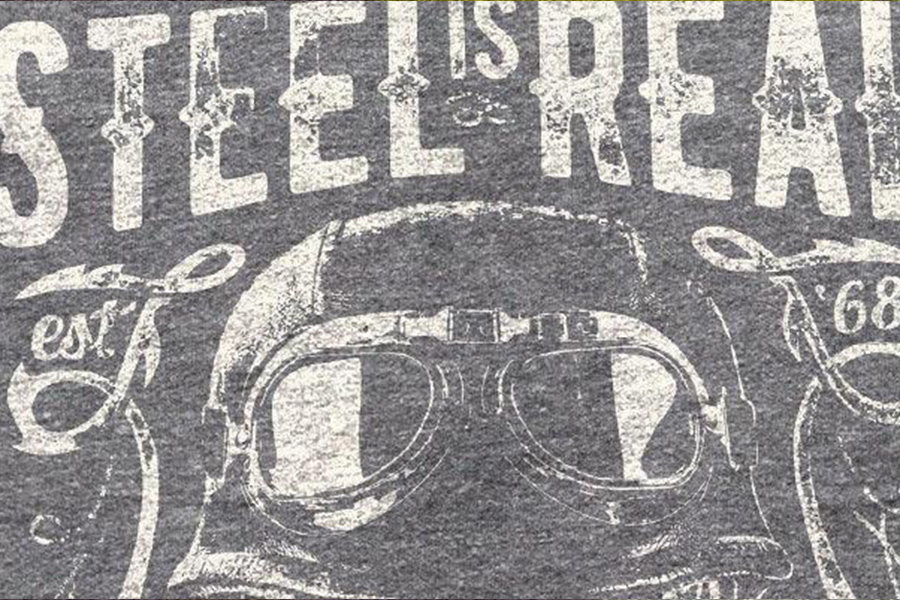

Unlike plastisol, water-based printing provides a super-soft print, is easy to clean up, and does not require chemicals to clean off the inks. It is also a great eco-friendly option, because the inks can be easily washed down the drain and have low toxicity. This type of printing works best on lighter garments, because the colors are not as robust as those of plastisol inks.

Used on darker fabrics, water-based printing will give you a bit of a vintage or faded feel. If you have any questions on which print will look better on your t-shirts, it is best to ask the printers, as they have invaluable experience regarding the different printing techniques.

3. Discharge serigraph

The bleaching method

If you bleach out the dark part of a t-shirt, it will become much more vibrant and soft. This is because there will not be a thick cover of ink over the garment when bleaching is used. Instead of normal ink, discharge inks that remove the t-shirt’s dye are used. In design, this technique is related to bleaching, except it does not damage the fibers, and will change the color of the garment to whatever color you choose.

The way t-shirts react to the discharge printing process can be different. Most printers have preferred textures and even preferred colors to work on when using the discharge printing method. A benefit of using discharge printing is that after the first wash, the t-shirt becomes very soft, and you can barely feel the print.

Discharge printing is a more difficult process than water-based or plastisol printing. If this method is chosen, it is recommended for a high-quality printer to be used.

4. CMYK printing

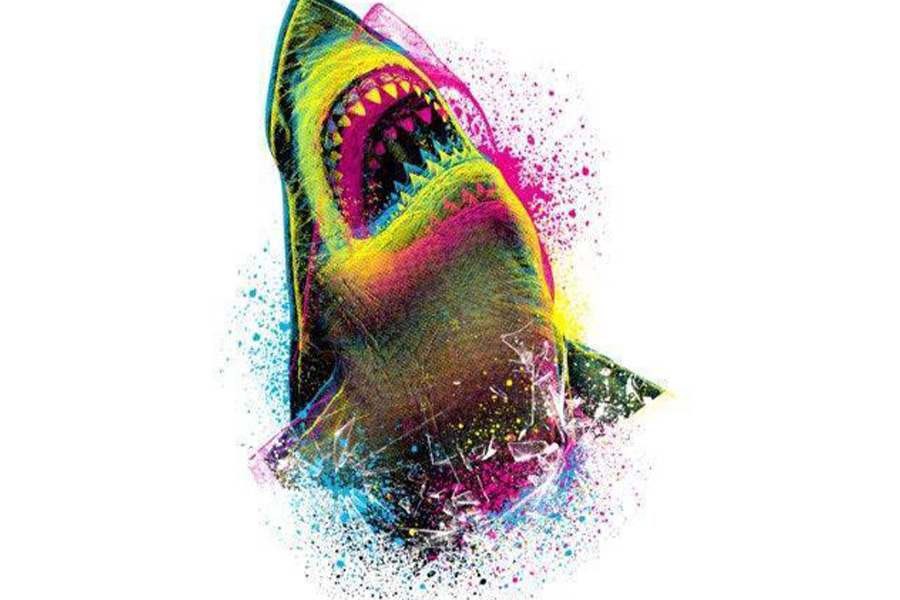

Uses cyan, yellow, magenta, and black to emulate a photorealistic print

While the print will not be quite as crisp as the real thing, it will certainly come close! CMYK printing (also known as four-color process printing) is another serigraph printing technique that printers can use.

It may be surprising that such vibrant and accurate prints can be achieved from just four base colors, but you can combine those four colors to get incredible color detail and depth. This form of simulated process printing is a highly technical task for printers, so it is recommended for an experienced printer to undertake the task, especially for the color separation process.

The design is first run through software that breaks up the colors, then the darkness of all the films is manually adjusted. Some testing may also be done to calibrate the different color layers.

5. Foil printing

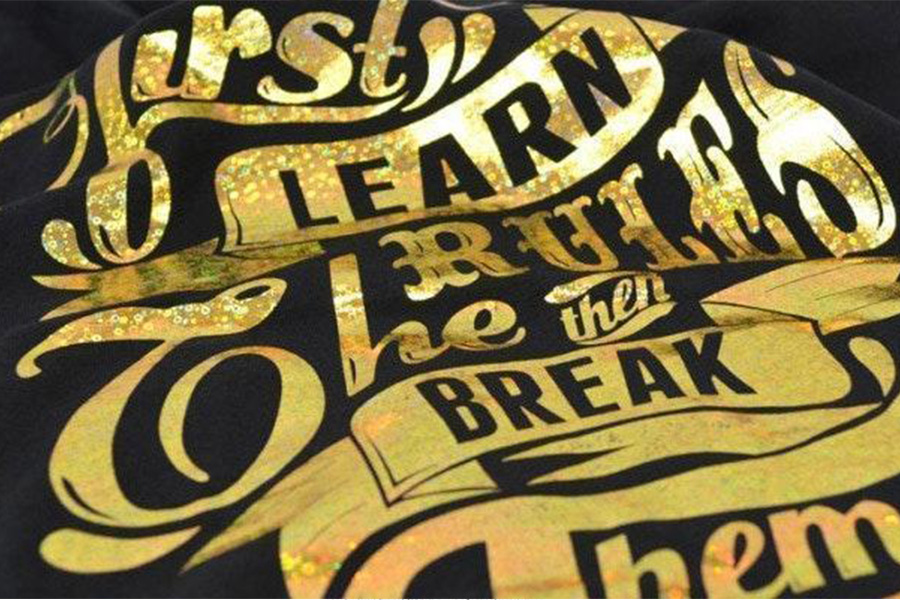

Used for a metallic effect

The foil printing method is used for applying golden or metallic prints on garments. The t-shirt is first covered with an adhesive, then foil is put over the adhesive. Once it is laid down, the excess is removed. The foil will remain on the parts of the t-shirt that had adhesive and be removed from everywhere else.

Foil printed t-shirts do not usually hold the print long after a number of washes. An alternative way of achieving a similar metallic effect is by using metallic inks. They will not be as shiny, but they will hold up much longer. Another benefit is that they are cheaper.

6. Dye sublimation serigraph

All-over t-shirt print

Dye sublimation is a serigraph printing technique that is used by a lot of print-on-demand printers. It involves the design being printed out onto a large piece of paper, which is usually large enough to cover the entire t-shirt. The special type of paper used for this is called sublimation paper.

The design is first printed out on the large sheet of sublimation paper, then it is turned over, so the ink comes into contact with the t-shirt. After that, a heat press compresses the ink onto the t-shirt, causing it to stick. When the sublimation paper is removed, the colorful design appears on the t-shirt.

It is important to note that dye sublimation cannot be used for 100% cotton t-shirts, as the t-shirt needs to have a high polyester count for the printing technique to work.

It is still a very cool printing method because it is full-color, meaning that you can use as many colors as you want, and it will not impact the price. However, when looked at relative to the other printing methods, dye sublimation is the most expensive way of printing t-shirts, as there are many steps involved, and it uses a lot of ink. So price-wise, it is at the opposite end of the range from plastisol ink printing.

Find the right serigraph printing method for you

On the whole, screen printing provides a wide variety of options, and the colors hold up really well.

Printers can use screen printing for various types of printing, from basic to high-end product printing.

Source from kingjetprinter.com